45

400 Series

Maintenance and service

Safety instructions - Read safety

instructions before any maintenance

work

Avoid injury during maintenance

work - Follow all instructions

and safety precautions during

maintenance.

• Stop the engine and let it cool down

before any inspection, maintenance,

or service operation.

• Lock the boom lift cylinder with the

service support before going under

the boom.

• Apply parking brake. Always park

the loader on level surface before

maintenance work.

• Install the frame lock when lifting

the machine, for instance when

changing tires.

• Before working on the engine or

equipment, disconnect the battery.

Risk of burns - Hot parts. Allow

engine to cool before accessing the

engine. Engine and exhaust parts may

be extremely hot after use.

The adjacent warning label is located

near the engine. Hot areas include

the engine in general, and especially

its exhaust pipe(s) and surrounding

areas.

Maintenance of hydraulic systems

Check hydraulic hoses and components only when the

engine is stopped and hydraulic pressure is released.

Repair all leaks as soon as you have noticed them,

because a small leak can quickly change into a big one.

Do not operate the machine if you have noticed faults

or leaks in hydraulic system. Leaking hydraulic uid can

cause serious personal injuries and is harmful to the

environment.

Check hydraulic hoses for cracks and wear. Follow the

wear of the hoses and stop operation if the outer layer of

any hose has worn out. If there are signs of oil leakage,

put a piece of cardboard under the probable leakage

place in order to nd the leakage. If you nd a fault, the

hose or the component must be replaced. Contact your

Avant dealer or service for spare parts.

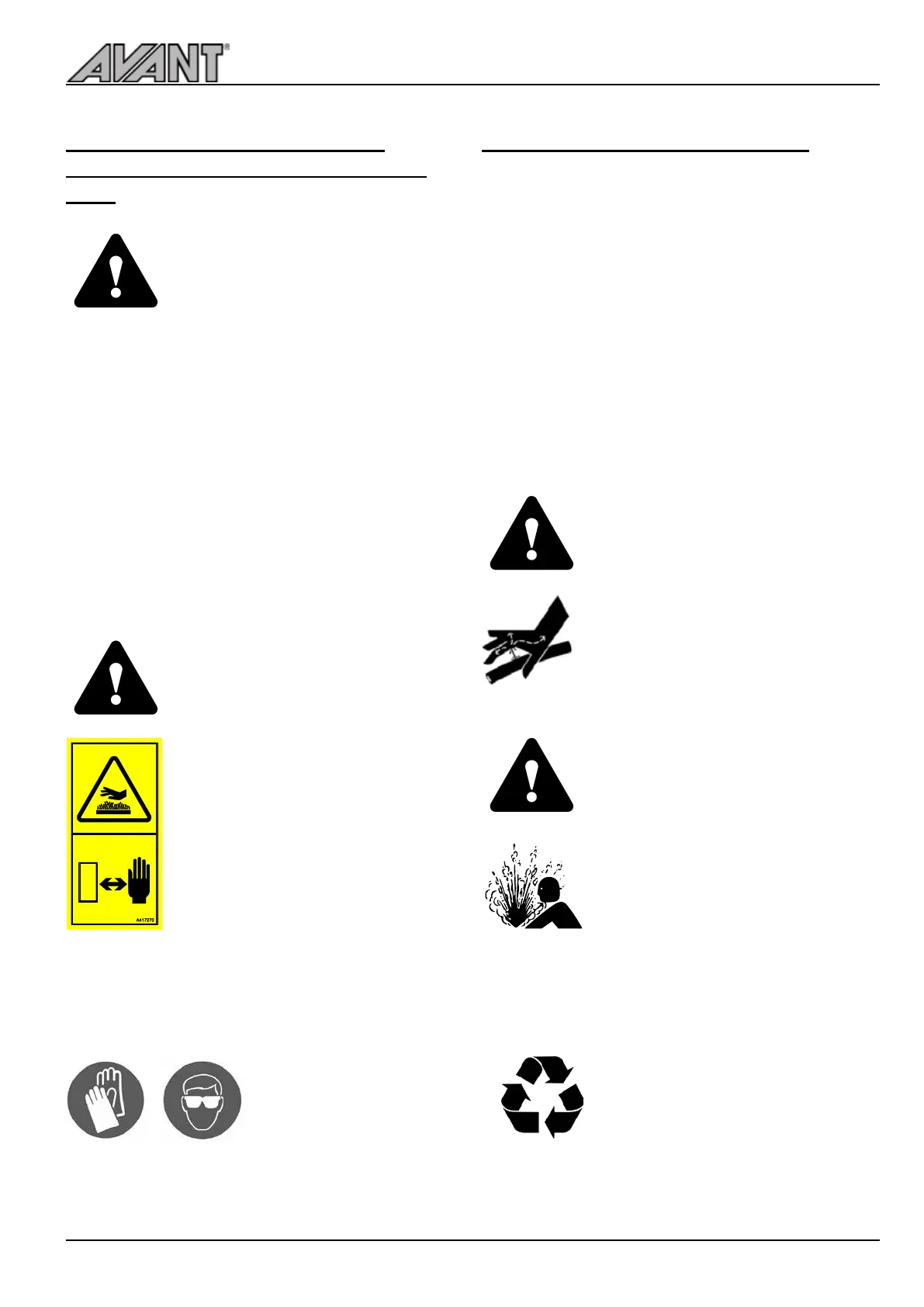

Never handle hydraulic

components if hydraulic system

is pressurized - Risk of injection

of hydraulic oil through skin. High

pressure hydraulic uid can cause

serious injuries. Never use hands

to search for leaks. Do not operate

the machine if you have noticed a

fault in the hydraulic system. See a

doctor immediately if hydraulic uid

penetrates your skin.

Risk of burst of hydraulic oil -

Isolate hydraulic accumulator

before service (Loaders equipped

with optional Smooth Drive system

only).

If the loader is equipped with the

smooth drive option, a pressure

accumulator is tted to the boom

hydraulic circuit. Do not disconnect

any hydarulic component before the

accumulator has been isolated from

the circuit and the residual pressure

has been released.

The uids in the machine are harmful to

the environment. Take waste oil and uids

to recycling station according to the local

regulations in your area.

Wear protective glasses and

gloves when servicing the

machine.

WARNING

WARNING

WARNING

WARNING

Loading...

Loading...