BTL5-A/C/E/G1_-M/U_ _ _ _-K-SR 32/K_ _

Micropulse Linear Transducer - Rod Style

4

english

3 Installation (cont.)

3.2 Transducer, Installation

The smallest permissible distance

between magnet ring and rod

mounting surface is shown in

Fig. 3-2.

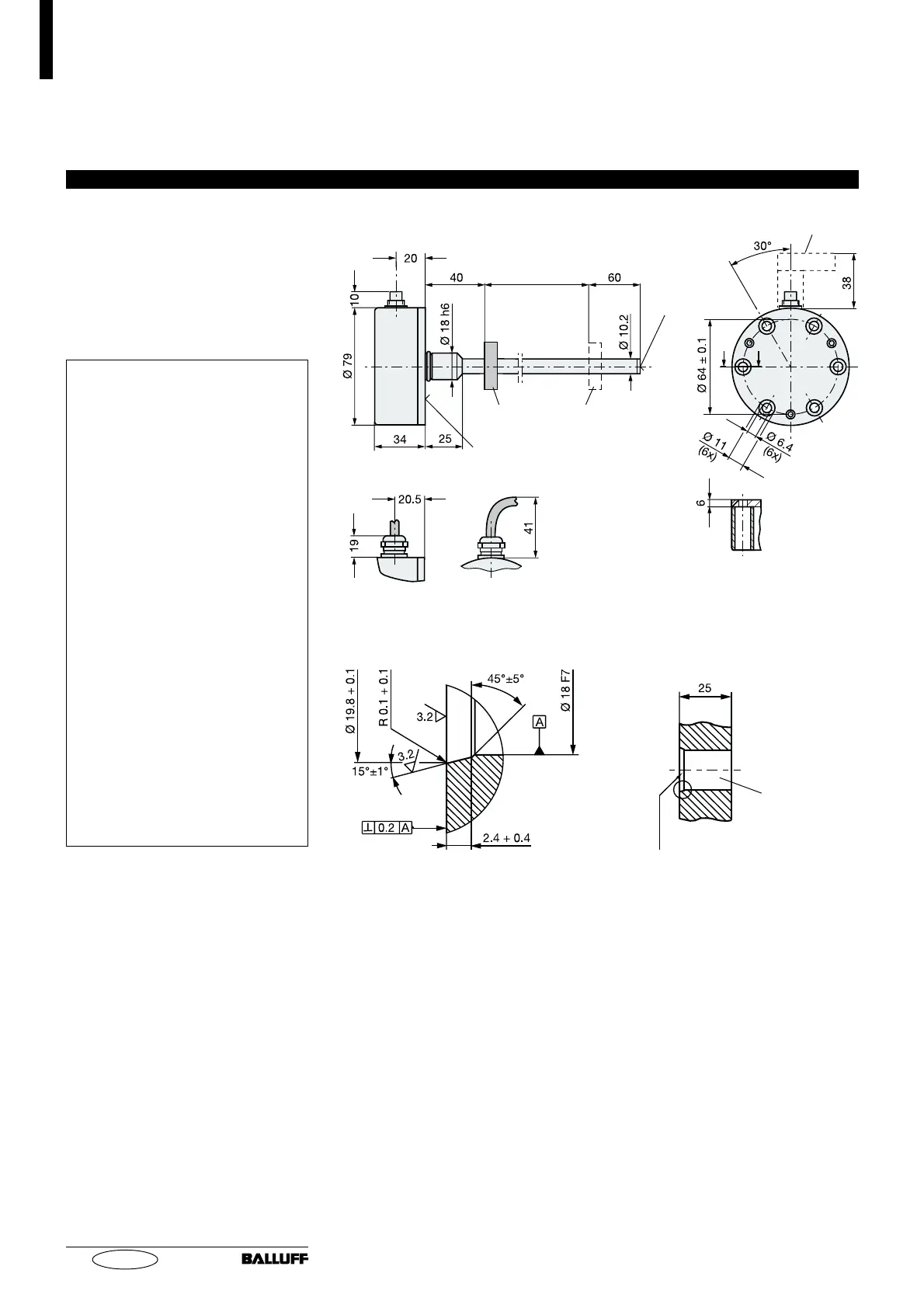

The sealing is carried cut with the

O-ring supplied at the flange facing.

Important Installation Notes:

The contact surface of the trans-

ducer must be completely con-

tacted by the mounting surface.

The O-ring supplied must make a

perfect pressure seal, i.e. the

bevel for the O-ring must be con-

figured exactly as shown in

Fig. 3-3.

To achieve a secure mounting,

attach the transducer with all

6 cylinder head screws ISO 4762,

M6 x 16 - A2-70 (

➥➥

➥➥

➥

Fig. 3-2). All

screws must be tightened to

3.5 Nm.

For horizontal mounting of trans-

ducer with stroke lengths greater

than 500 mm, the pressure tube

should be supported or attached

at its end.

When installing in a hydraulic

cylinder, do not allow the magnet

ring to rub against the pressure

tube. The bore diameter in the

piston and cylinder rod should be

at least 13 mm.

BTL5...K-K05

BTL5...K-SR 32

Damping zone

(unusable area)

threaded hole

M4 x 4/6 deep

Nominal

length

= stroke

Mounting surface

Connector BKS-S 33M

rotates in 90° steps

Magnet ring

6 holes for

mounting the

transducer

Fig. 3-2: Transducer BTL5...K..., dimensions

Fig. 3-3: Thru-hole design for mounting BTL with O-ring

thru-hole

Bevel for O-Ring 15.4 x 2.1

Loading...

Loading...