Adjustment of Belt Tension

Be sure to stop the engine before adjusting

the belts.

Before making sure of belt tension, rotate the

belt several times.

If the belt becomes slack due to frequent use, it

may jump or slip.

In addition, if it is overtightened, it may wear

prematurely.

If necessary, adjust it, and always check the

belt for appropriate tension.

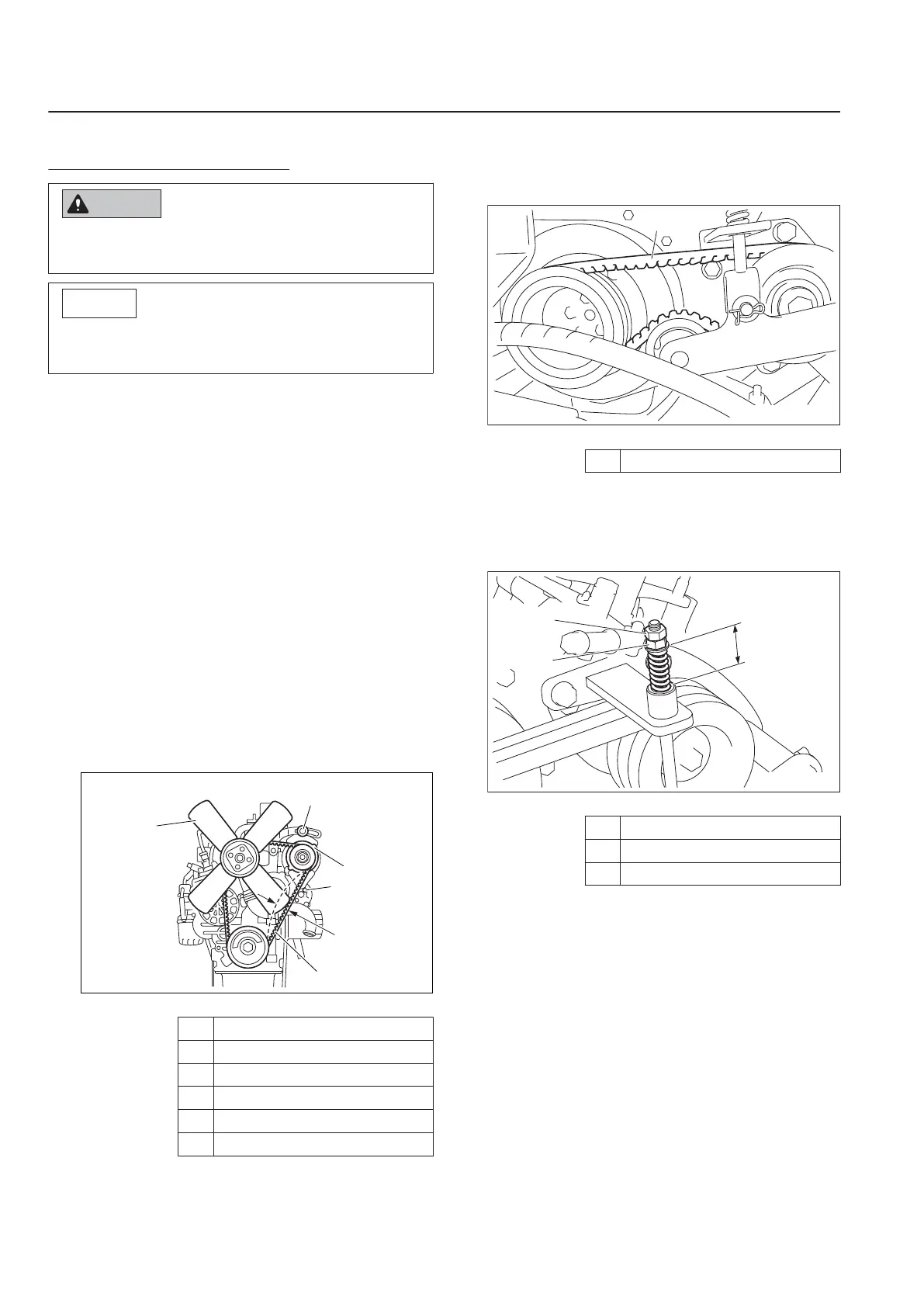

Fan Belt

Press the middle of the belt with your finger

to check the belt tension.

The belt tension is appropriate when the

belt slacks by approximately 10.0 mm (0.39

in) when you apply a force of 98 N (10 kgf)

to the belt at the middle point between the

pulleys.

If the belt tension is incorrect, loosen bolt A

and bolt B (securing the alternator), and

then move the alternator to adjust the

tension.

Fan Belt_001

1

Fan Belt

2 Blade

3 Alternator

4 Bolt A

5 Bolt B

A 10 mm (0.39 in)

1.

2.

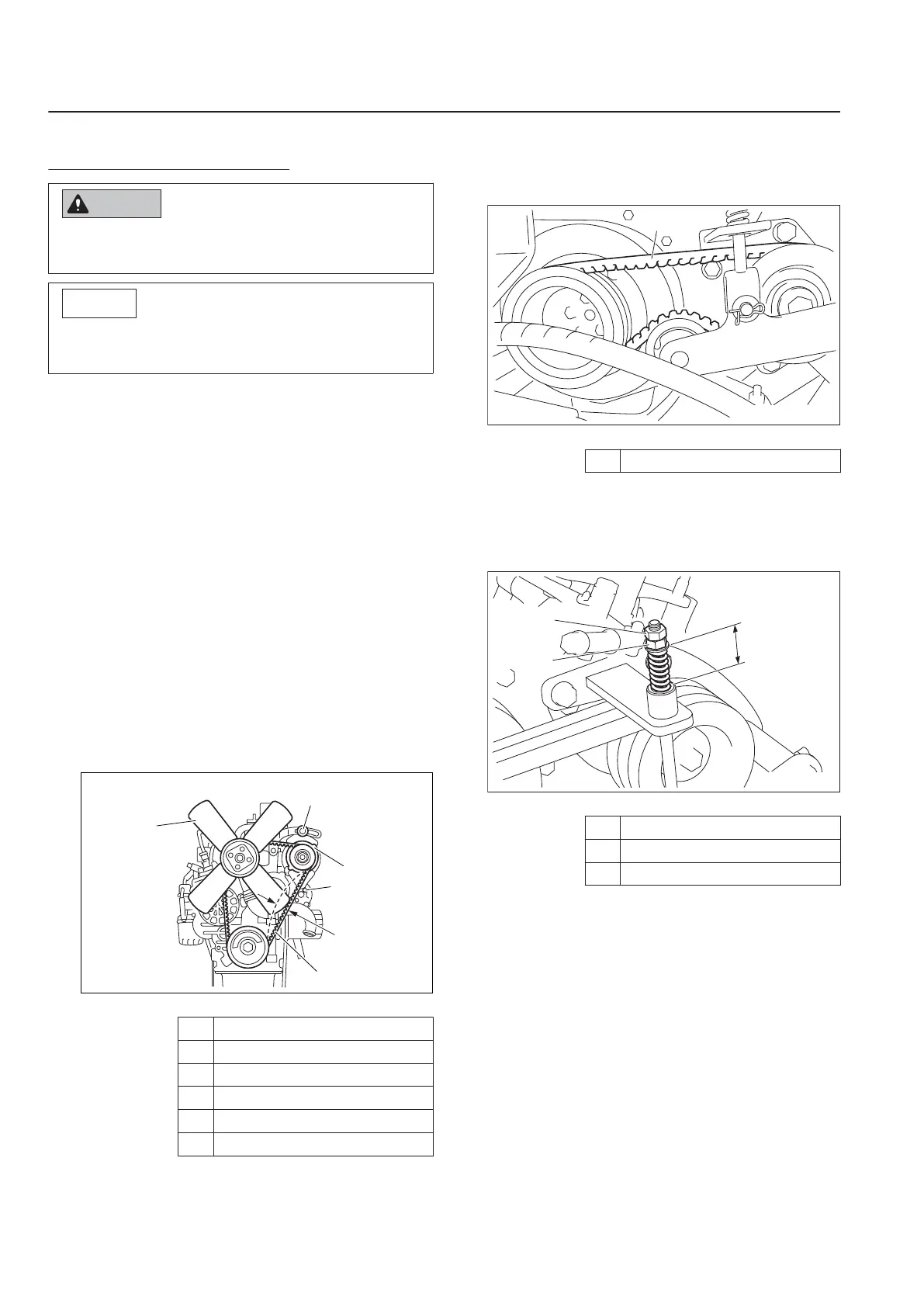

Hydraulic Pump Drive Belt

Open the hood.

Hydraulic Pump Drive Belt_001

1

Hydraulic pump drive belt

Loosen the lock nut, and then turn the nut

to adjust the length of the spring to 35.0

mm (1.38 in).

Secure with the lock nut.

Hydraulic Pump Drive Belt_002

1

Lock nut

2 Nut

A 30.0 - 35.0 mm (1.18 - 1.38 in)

1.

2.

3.

LM331

Maintenance

Page 6-10

Adjustment and Replacement

Loading...

Loading...