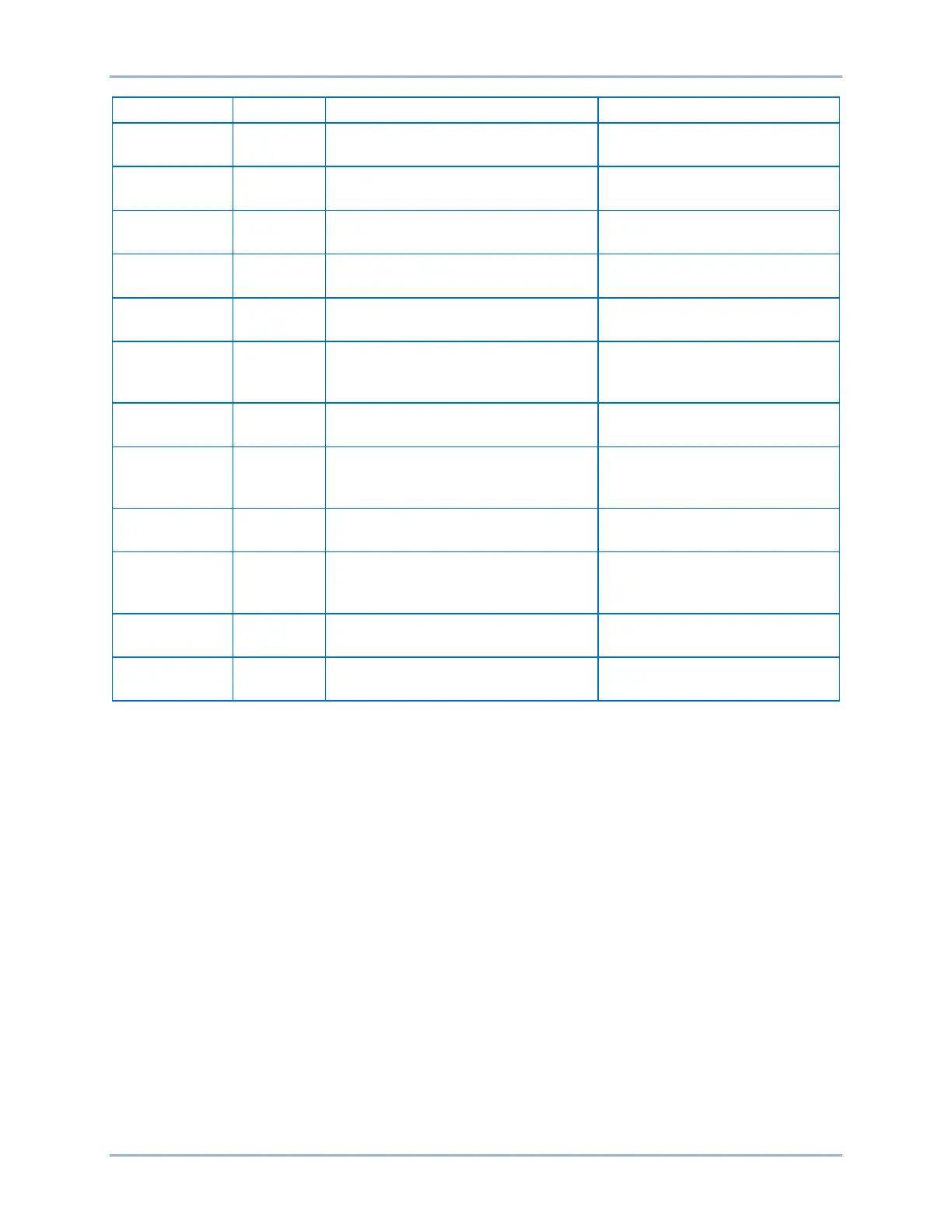

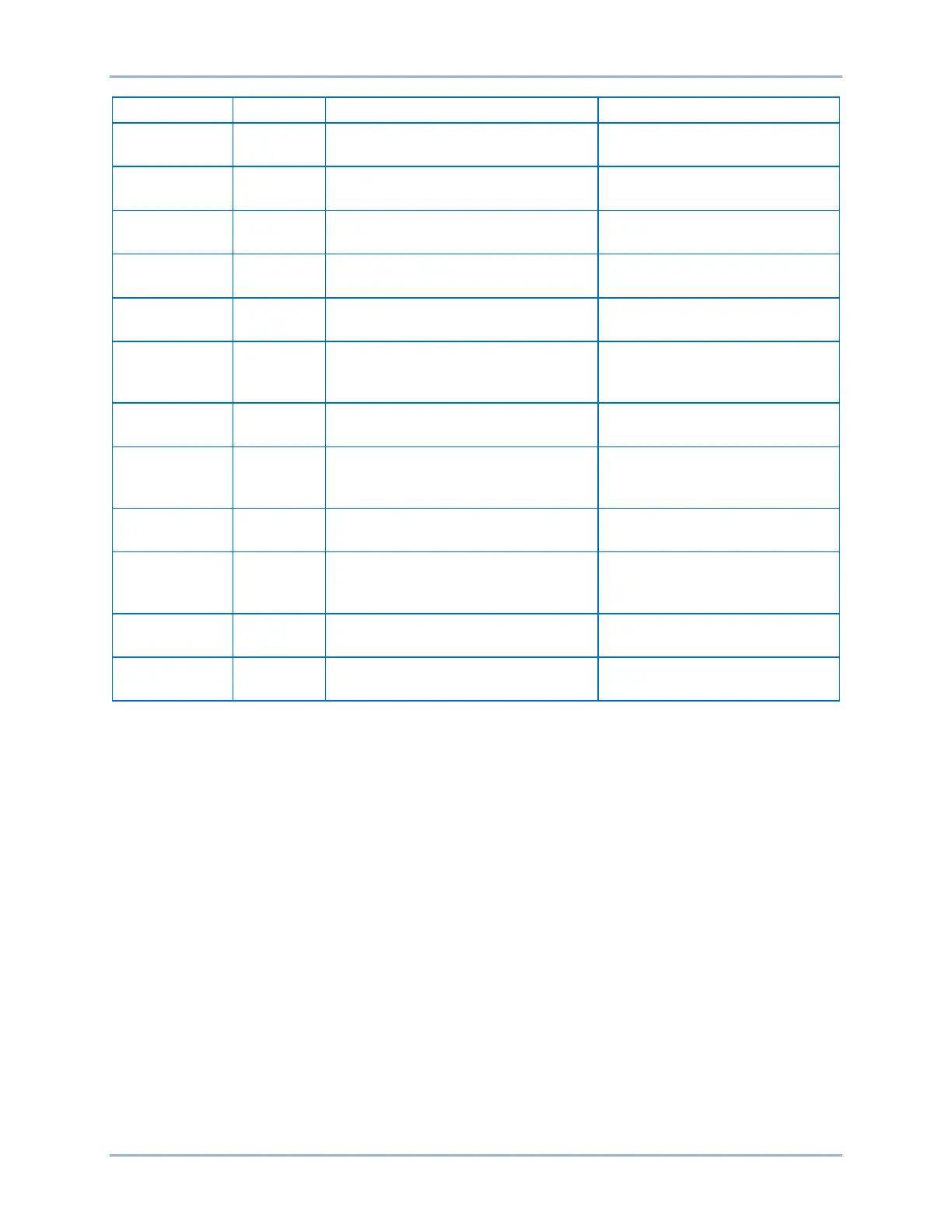

66-4 9424200996

Phase Current Differential (87) Test BE1-11m

System Parameters, Sensing

Transformers

System Parameters, Sensing

Transformers

Sets phase VT connection to

4W-Y

System Parameters, Sensing

Transformers

Sets 27/59 mode to phase-

neutral

System Parameters, Sensing

Transformers

Sets the tap for circuit 1 to 2.00

A secondary

System Parameters, Sensing

Transformers

Sets the tap for circuit 2 to 2.00

A secondary

Differential

Protection, Current, Phase

Differential (87)

Sets the type of operation

protection to traditional phase

Protection, Current, Phase

Differential (87)

Sets the element to operate

using average restraint current

Pickup (MOT)

Protection, Current, Phase

Differential (87)

Sets the minimum amount of

operate current required for a

Protection, Current, Phase

Differential (87)

Sets the 1

st

slope of the restraint

characteristic to 20%

Pickup (MOT)

Protection, Current, Phase

Differential (87)

The 2

nd

slope is active when the

measured maximum restraint

current is greater 3x tap

Protection, Current, Phase

Differential (87)

Sets the 2

nd

slope of the

restraint characteristic to 40%

Protection, Current, Phase

Differential (87)

Sets the trip time delay to 100

ms

Step 2: Use BESTCOMSPlus to configure the BESTlogicPlus programmable logic previously shown in

Figure 66-1.

Step 3: Prepare to monitor the 87R function operation. Operation can be verified by monitoring OUT2

(see Figure 66-1).

Step 4: To test the Minimum Restrained Pickup setting, connect two balanced three-phase current

sources to the BE1-11m in ABC rotation: 0.5∠0°, 0.5∠–120°, 0.5∠120° amps to terminals D1

through D6 and 0.5∠180°, 0.5∠60°, 0.5∠–60° amps to terminals F1 through F6 (0.25x tap).

Step 5: Slowly increase the A-phase current in CT circuit 1 or 2 until OUT2 closes and record the

pickup. This should occur at 0.70 A ±0.05 A. Verify that there is an 87A target on the front-panel

display.

Step 6: Slowly decrease the A-phase current in CT circuit 1 or 2 until OUT2 reopens and record the

dropout. See the functional test report for acceptable ranges.

Step 7: Reset to the current levels in step 4 and reset all targets.

Step 8: Slowly decrease the A-phase current in CT circuit 1 or 2 until OUT2 closes and record the

pickup. This should occur at 0.30 A ±0.05 A. Verify that there is an 87A target on the front-panel

display.

Step 9: Slowly increase the A-phase current in CT circuit 1 or 2 until OUT2 reopens and record the

dropout. See the functional test report for acceptable ranges.

Loading...

Loading...