Acceleration pre-control

Function description 15

Version: 1.5

4 Acceleration pre-control

The lag error of an axis during acceleration can be minimized with the aid of the acceleration pre-control.

This can, for example, shorten the cycle times of handling axes or improved the path fidelity of CNC axes.

The meaning of the parameters in conjunction with the acceleration pre-control is explained in the following

chapters.

Note

Reference variables for the acceleration pre-control

P-0-0010, P-0-0071, P-0-0505, P-0-0556, S-0-0348

Requirements

The acceleration pre-control can only be used if the AX5000 is op-

erated in

• 11: position control feedback 1 lag less

or

• 12: position control feedback 2 lag less mode.

The AX5000 receives a new set position value cyclically (e.g. every

2 ms) and interpolates between the new set values with the cycle

time of the position controller (default value 250 µs).

The acceleration results from the second derivative of the position.

In the case of linear interpolation of the set values the value of the

second derivative is always zero.

Therefore cubic interpolation must be set in the AX5000

(P-0-0556):

If cubic interpolation is active, the cycle time of the position con-

troller in the AX5000 (P-0-0004) must not be shorter than 250 µs,

otherwise an error message (F330) will appear.

The acceleration pre-control should be used if possible with a

firmware version ≥ FW v2.10 build 8. The function has already

been implemented in previous versions, but not with the functional-

ity described here.

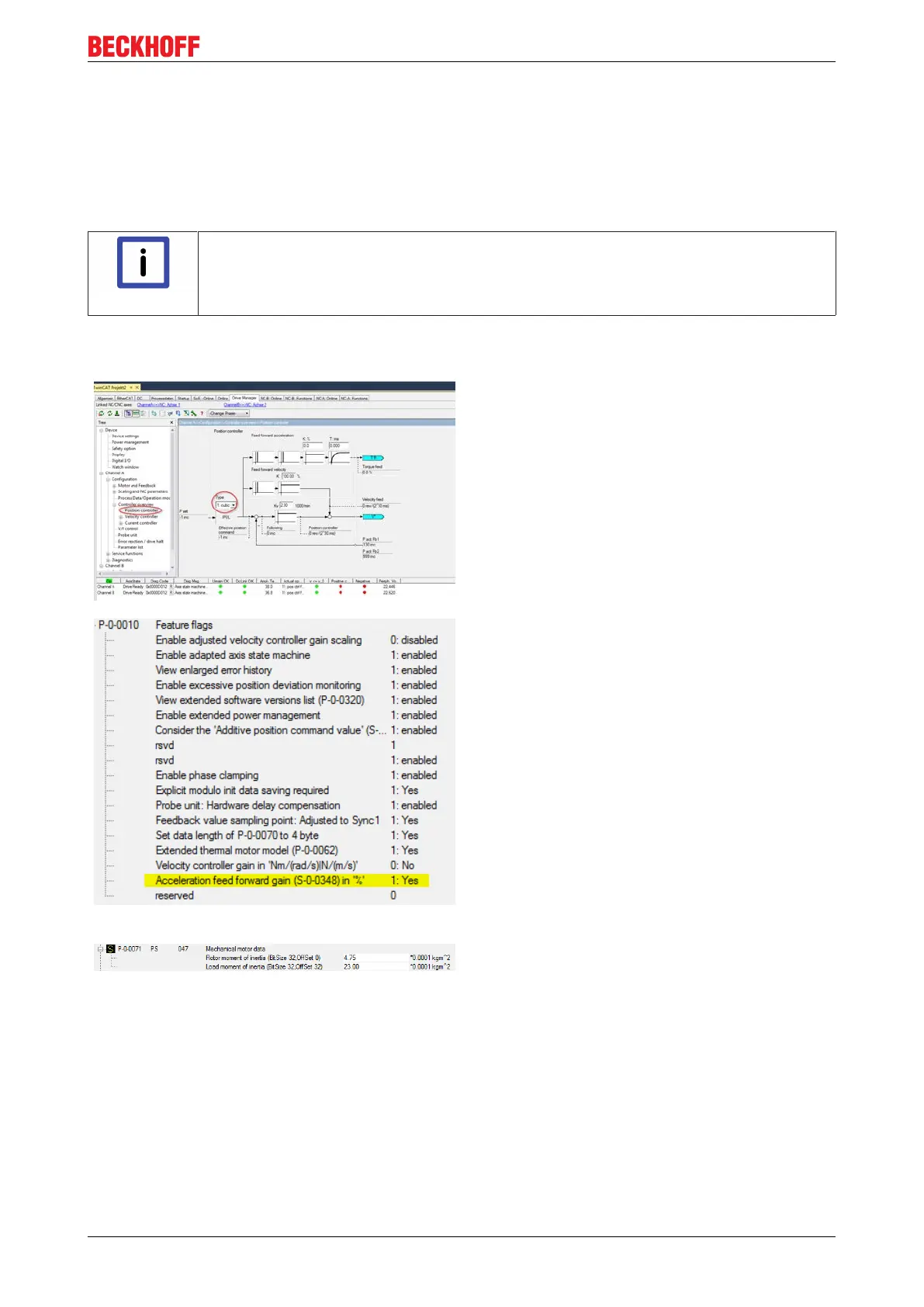

In parameter P-0-0010 "Feature Flags", the associated bit must be

activated so that the scaling of the pre-control takes place in %:

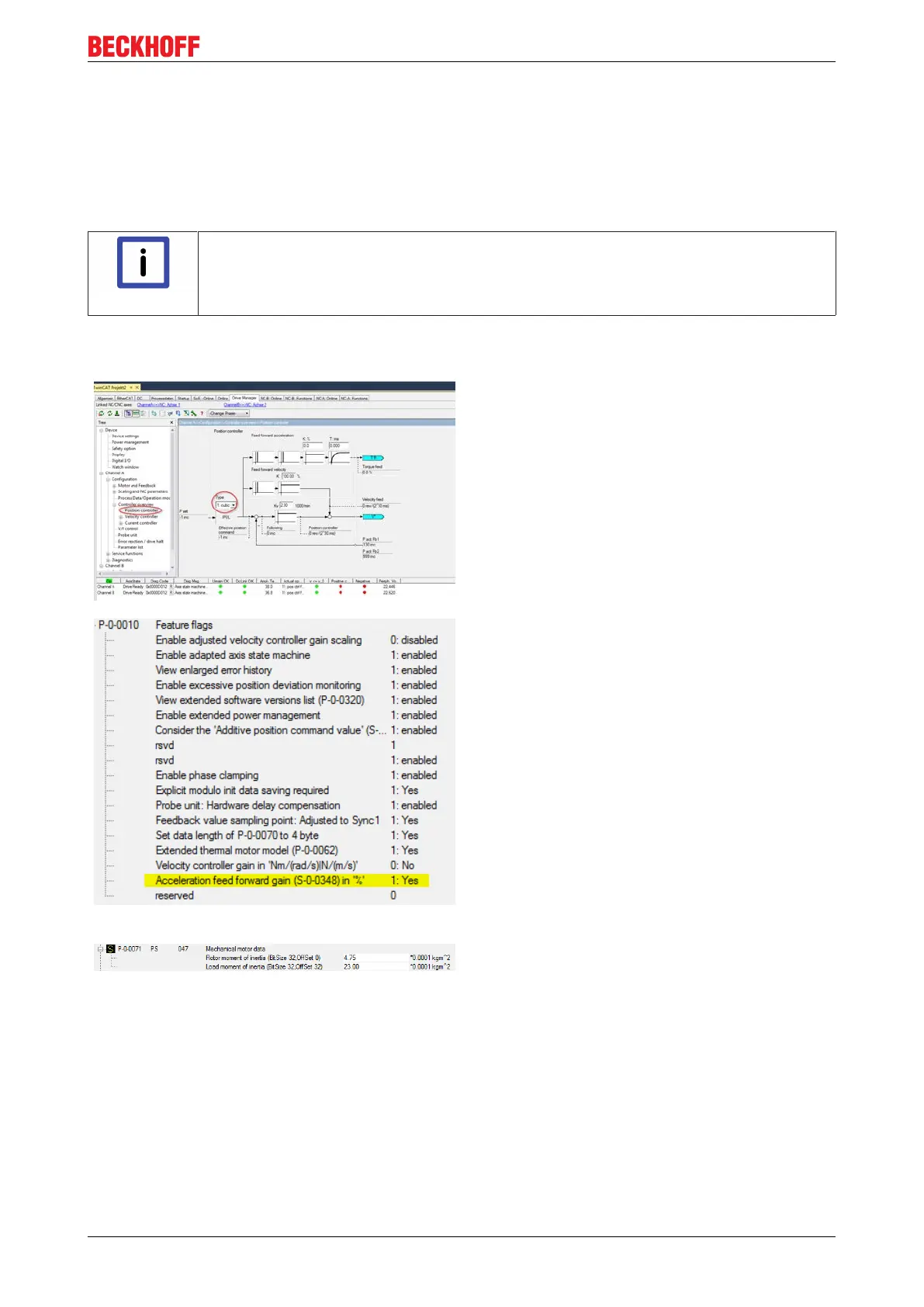

A value for the current is calculated from the acceleration, depend-

ing on the motor and the load conditions. For this, it is important

that the correct values for the mass inertia of the motor and the

load are entered in parameter P-0-0071:

The mass inertia of the motor is read automatically from the elec-

tronic name plate during the configuration.

If the exact value of the load inertia is not known it should be esti-

mated. In most servo applications the ratio of the load inertia to the

motor inertia has a value of between 3 and 10.

Loading...

Loading...