BestCode Next Series 8 Technical Manual October 2022 Page 206 of 290

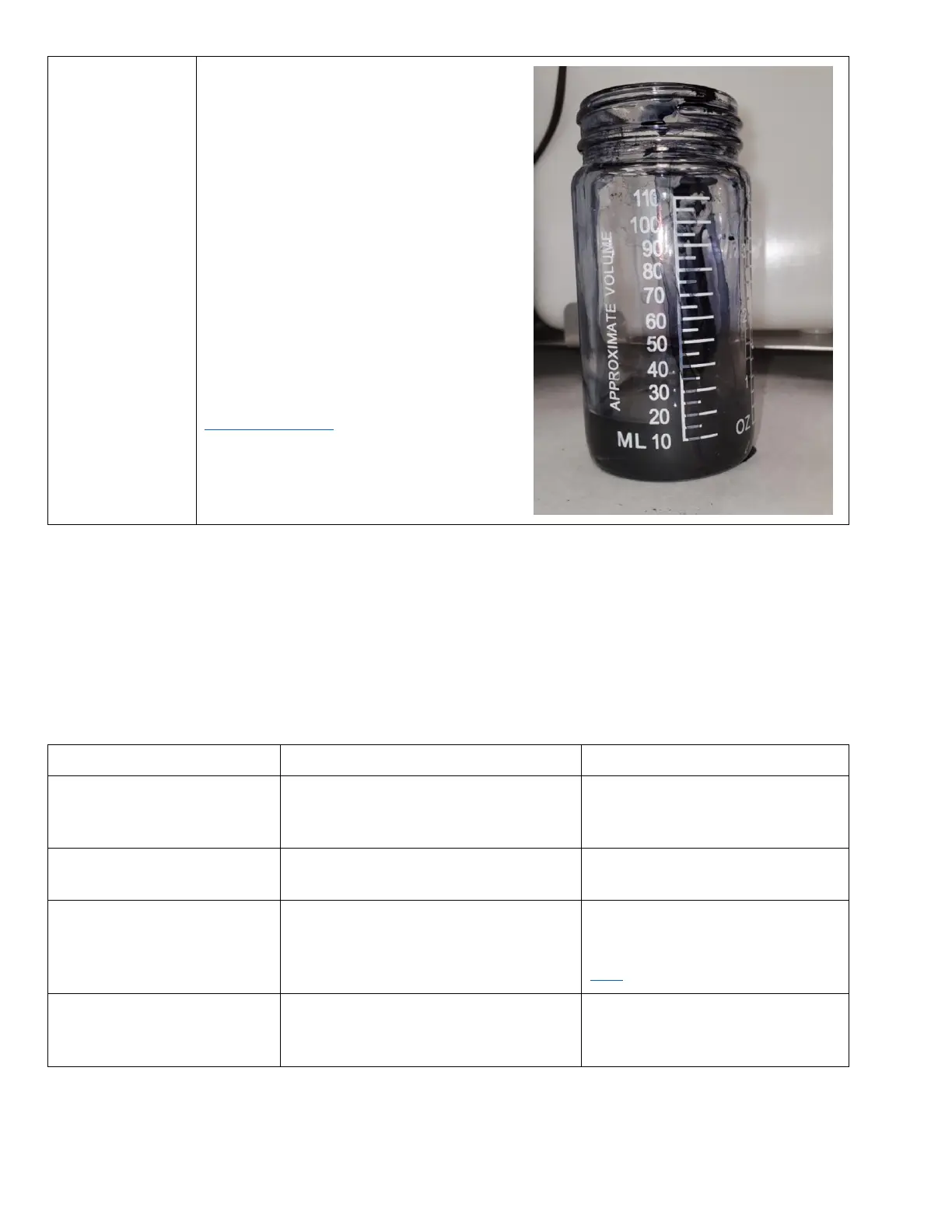

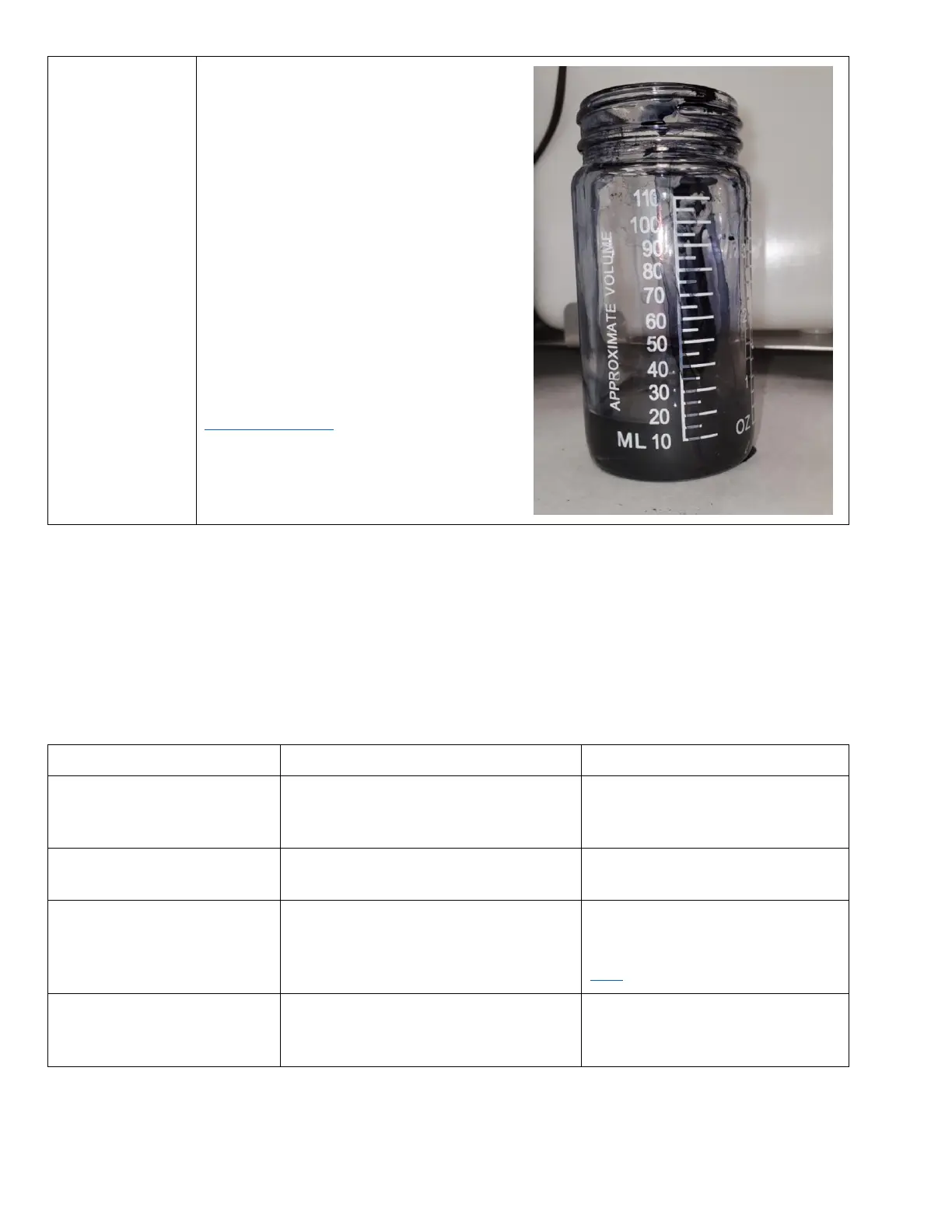

When the time reaches 60 seconds, disable the

pump and viscometer valve and Measure the

Graduated Cylinder.

For all models, there should be atleast 15ml of

Ink or about 0.5oz in the cylinder.

Less than this indicates a flow restriction inside

the viscometer.

Viscometer Cleaning is required.

Common CIJ Issues:

Common Fluidic Issues

Listed here are a few of the most encountered fluidic issues that require troubleshooting.

Pump Fault

Loose Connection

A loose connection on the pick-up side of the ink pump can result in pump faults.

Air Leak at the Tank Pickup

Tube is not fully inserted into the tank pick.

Can be caused by dried ink or deformed

tube.

Remove tube, cut tubing square or

replace tubing. Clean pickup push to

connect and re-insert.

Ink is very thick or dried in the tank and is

blocking the ink pickup

Discard tank, clean pickup tube,

reassemble and install fresh ink.

Air Leak at Pre-pump filter

Compression fittings on the Pre-pump filter

are loose or tube is not inserted deep

enough.

Remove tube, cut tubing square or

replace tubing. Insert tubing into Pre-

pump filter and tighten as instructed

here.

Tube is not fully inserted into the tank pick.

Can be caused by dried ink or deformed

tube

Remove tube, cut tubing square or

replace tubing. Clean pickup push to

connect and re-insert.

Loading...

Loading...