W1

T3

V1

T2

U1

T1

W5

T9

V5

T8

U5

T7

V2

T5

U2

T4

W1

T3

V1

T2

U1

T1

W5

T9

V5

T8

U5

T7

W2

T6

V2

T5

U2

T4

W2

T6

WWW.BIGASSSOLUTIONS.COM © 2016 DELTA T CORP. ALL RIGHTS RESERVED.

36

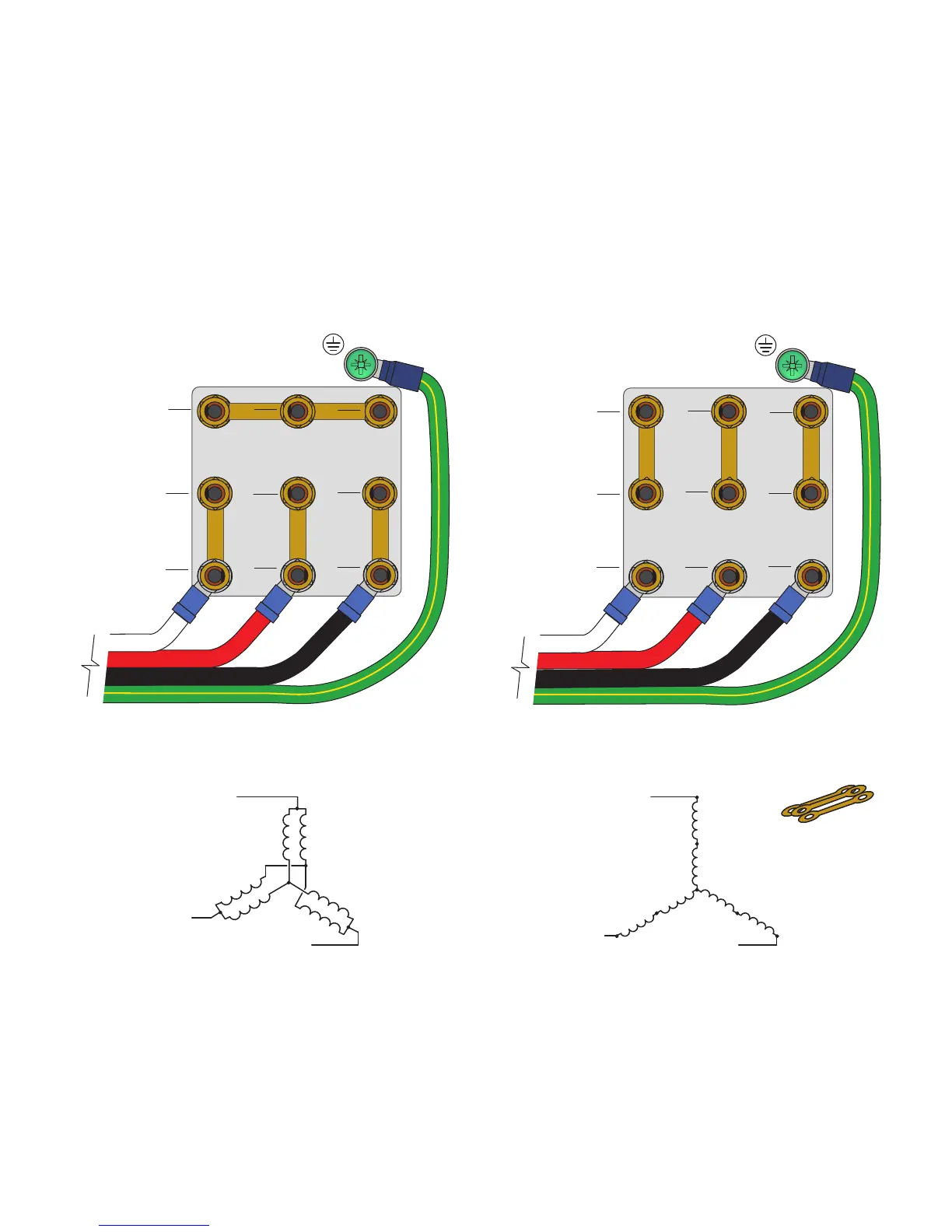

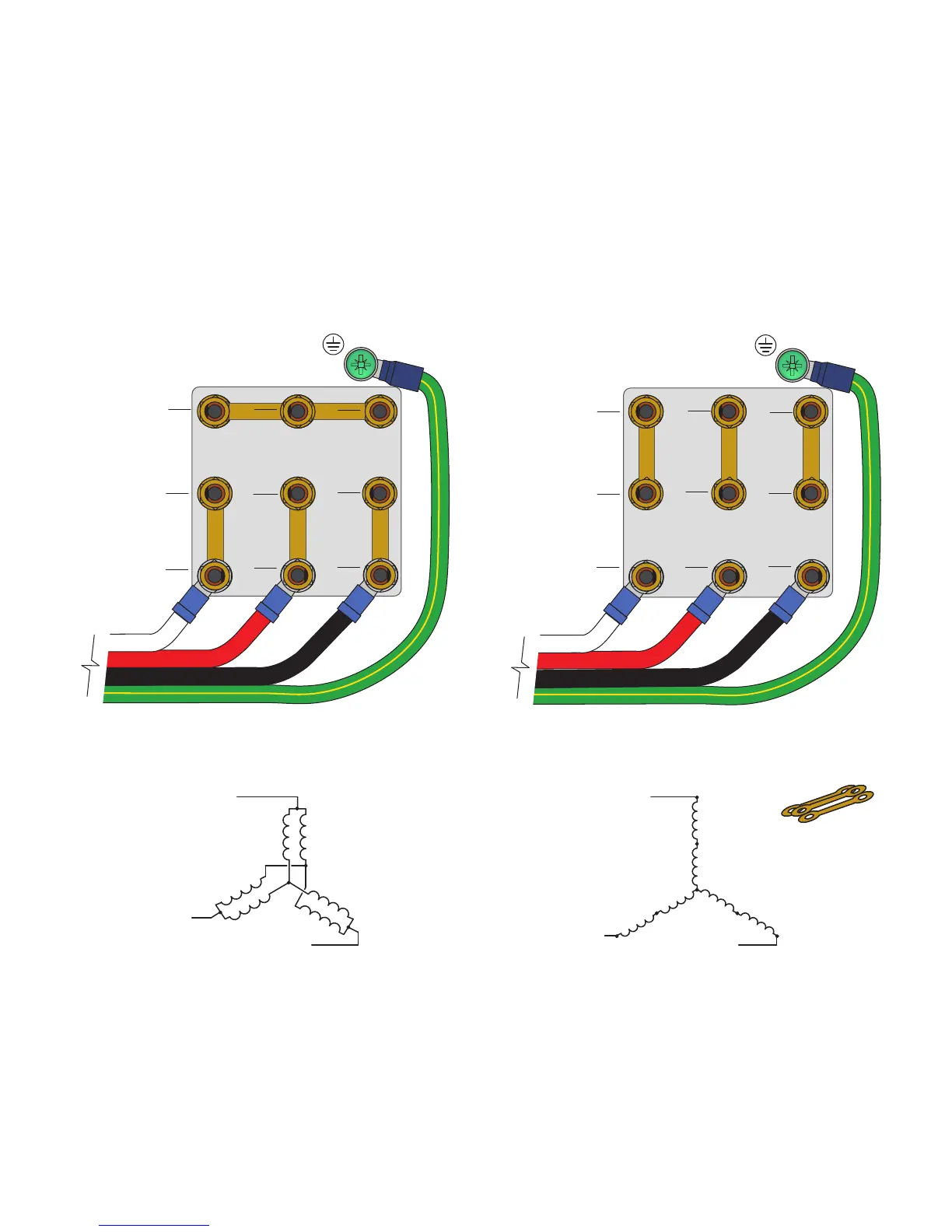

Motor Wiring: 9-Lead, Dual Voltage, Wye Motor Configurations

The motor wiring configurations shown below are applicable to 9-lead, dual voltage, wye wound motors rated for

230/460 VAC and 330/600 VAC. Consult the motor nameplate and/or wiring placard for verification of required

wiring connections. Motors with terminal blocks require ring terminals and a 7 mm nut driver for termination. The

diagrams below include L2 and L3 swap to yield proper motor rotation. Note: Swapping leads to reverse rotation

is done only on the output side of the drive.

Low Voltage

200–240 VAC, 50–60 Hz

330–350 VAC, 50–60 Hz

High Voltage

400–480 VAC, 50–60 Hz

575–600 VAC, 50–60 Hz

Jumper bars are

provided with the

motor

High Voltage

Low Voltage

GREEN W/ YELLOW TRACER

VAC from VFD

BLACK

GREEN W/ YELLOW TRACER

WHITE

RED

BLACK

WHITE

RED

VAC from VFD

Loading...

Loading...