Operating Instructions 500 E Global

Maintenance

8

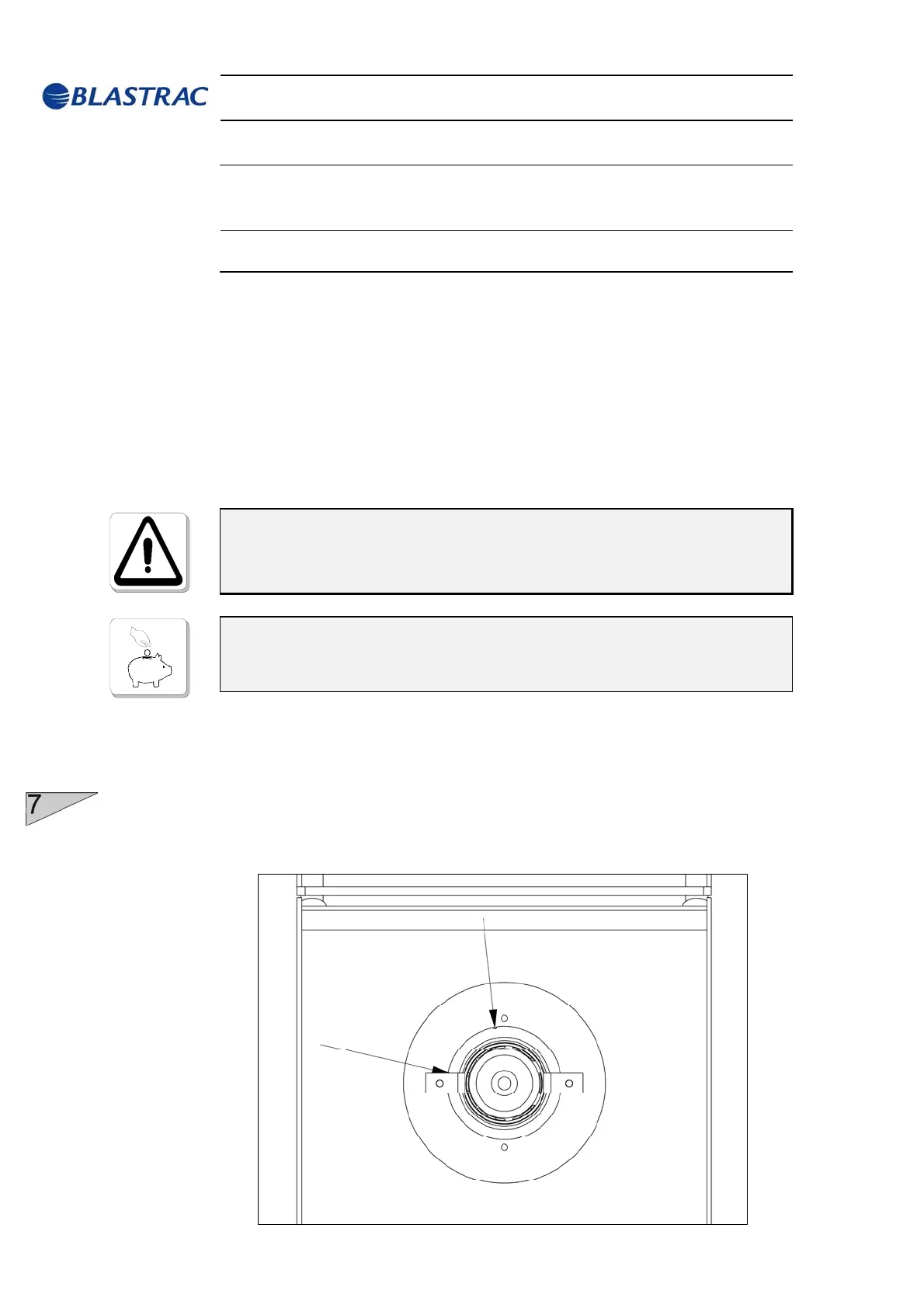

7.6 Setting the control cage

The adjustment is effected by loosening the cage clamps and turning

the control cage in the suitable direction. The cast grooves on the

control cage show the position of the control cage opening. The

following adjustment standard value is valid: the control cage opening

is approximately opposite to the throwing angle. The abrasive grain

size plays an important role here. Different types of abrasive have

different throwing characteristics due to their different weights and

frictional resistance. This means that you must never use different

types of abrasive at the same time.

The adjustment can be carried out as follows:

Determine the notches which indicate the upper and lower

window edges.

If the blast wheel is turning counter-clockwise, set the upper

notch of the control cage to imaginary 11.30 of a dial (fig. 7.2).

Fig. 7.2

Prior to any repair works on the machine and its drives,

secure the machine against unintentional switching-on. Put

the machine to its safety off position.

After fitting new spare parts always create a blast pattern in order

to check the blasting direction. This is the only way to grant

economical work and to avoid unnecessary wear and repair costs.

Loading...

Loading...