12

BOC Smootharc Multi 180/200 Operating manual

Installation

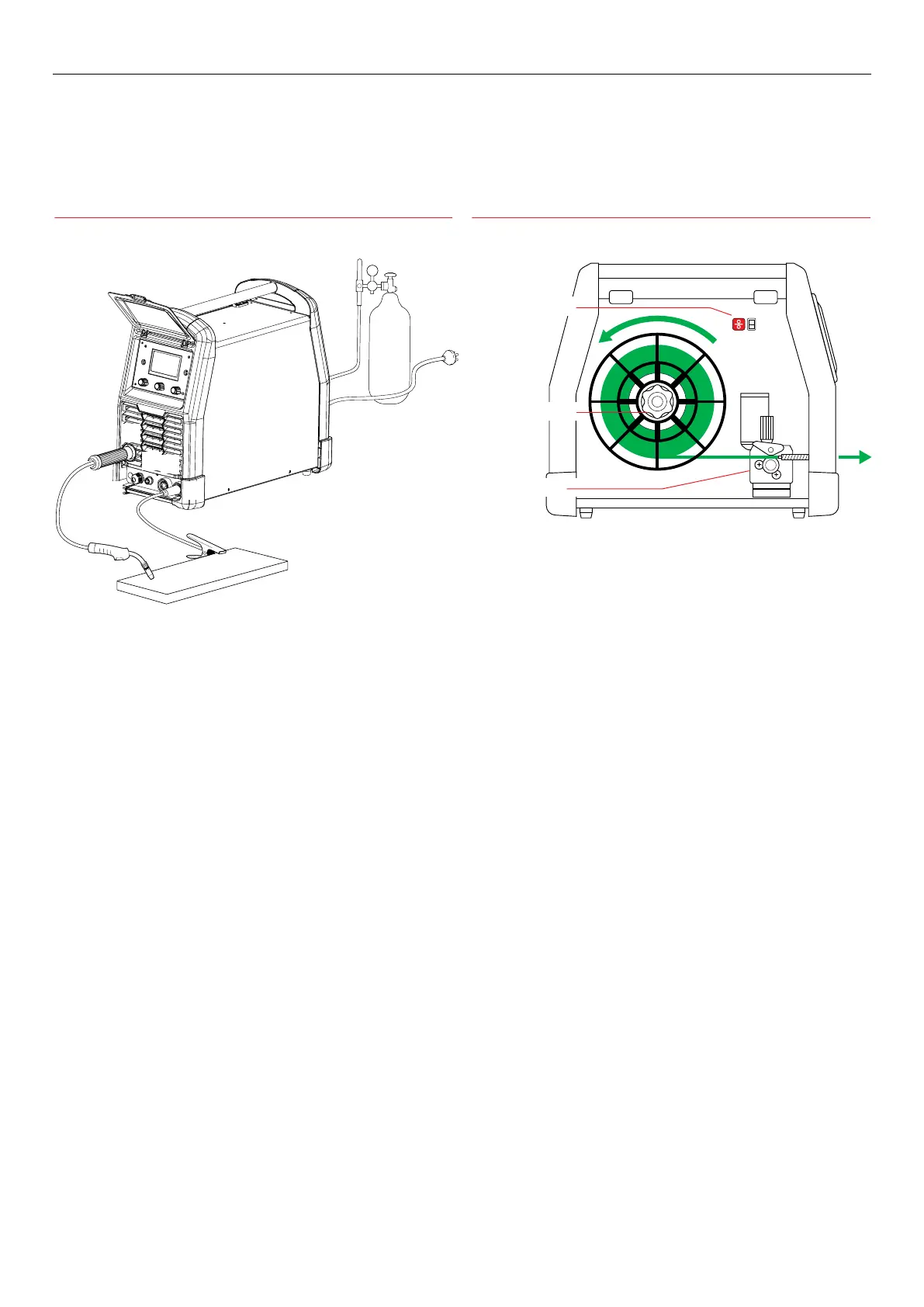

Installation for MIG/MAG process Wire feed installation

MIG/MAG

1. Connect the gas hose to the regulator and the rear of the machine.

Select correct shielding gas for the application.

2. Insert the [E] work return lead connector into [14] negative terminal

in the front panel.

3. Select correct welding wire for application (see page 38). Ensure you

are wearing safety glasses before loading wire into your machine. Fit

the wire spool to the machine.

4. Select the appropriate feed roller to suit the wire being used. This

machine comes complete with three types of wire feed rollers:

- V groove for use with solid carbon manganese and stainless steels;

- Knurled for use with FCAW wires;

- U groove for aluminium.

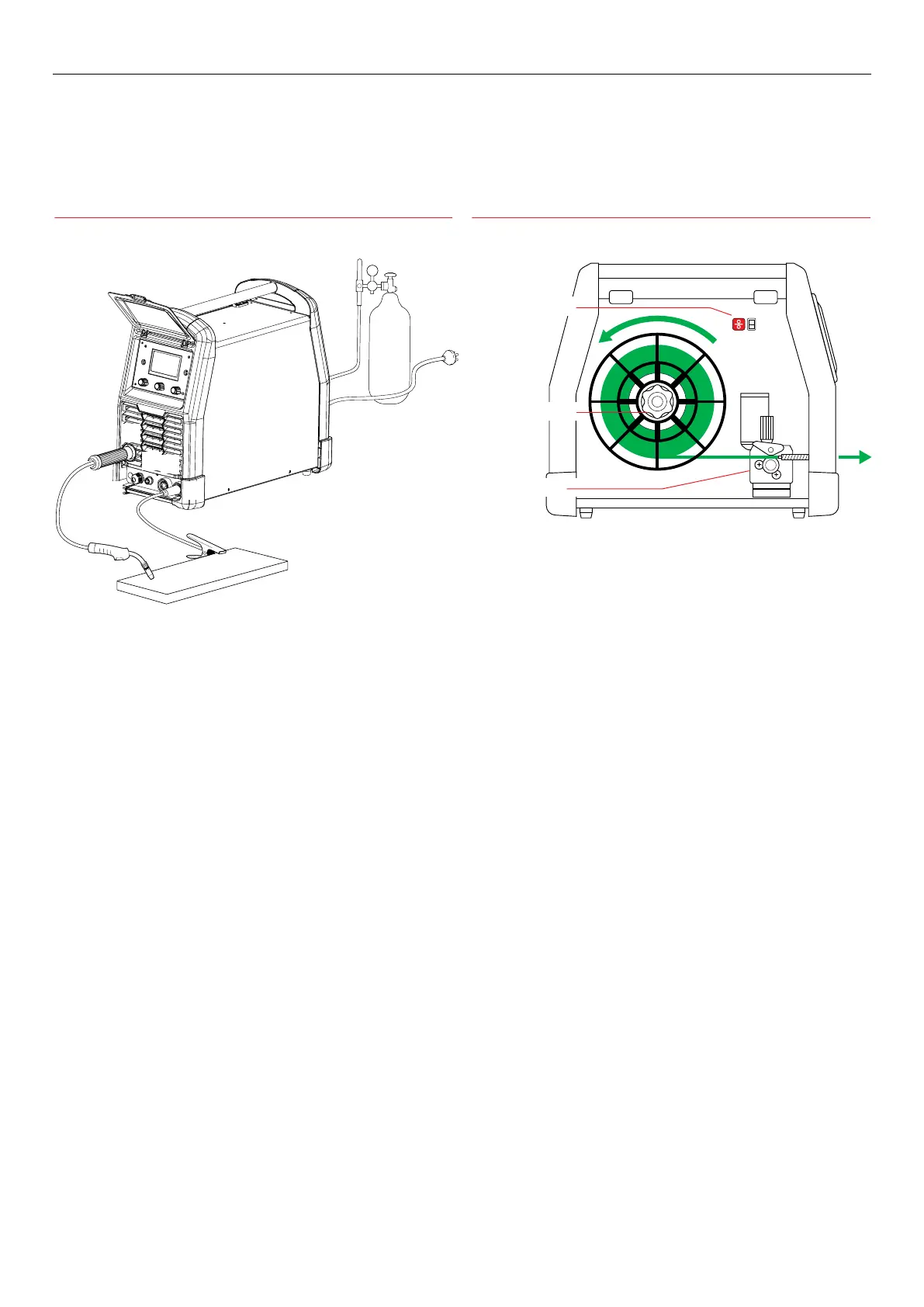

5. Install the wire: loosen the knurled nut from the spool holder; x

the welding wire reel onto the spool holder [3] so that the brake pin

locks into the spool bore; fasten the wire spool using the spool nut.

Ensure the welding wire reel is installed as per diagram above right,

feeding anti-clockwise.

6. Loosen the wire feed tension knob and insert the wire. Tension rollers

ensuring the wire is gripped suciently so as not to slip but avoid

over tightening as this can aect feed quality and cause wire feed

components to wear rapidly. Wire inching is achieved by pressing and

holding the torch trigger.

13

12

1411

A

10

E

3 Wire feed unit

2 Wire spool holder

1 Wire inch button

7. Fit and tighten the [A] torch on the [10] output connection. Ensure

correct torch liner and contact tip are selected.

8. Select the correct polarity for the type of wire used as indicated on

the consumable packaging. For most solid wires the terminal should

be set as torch positive. Therefore the [E] work return lead should be

connected to the [14] negative terminal.

Loading...

Loading...