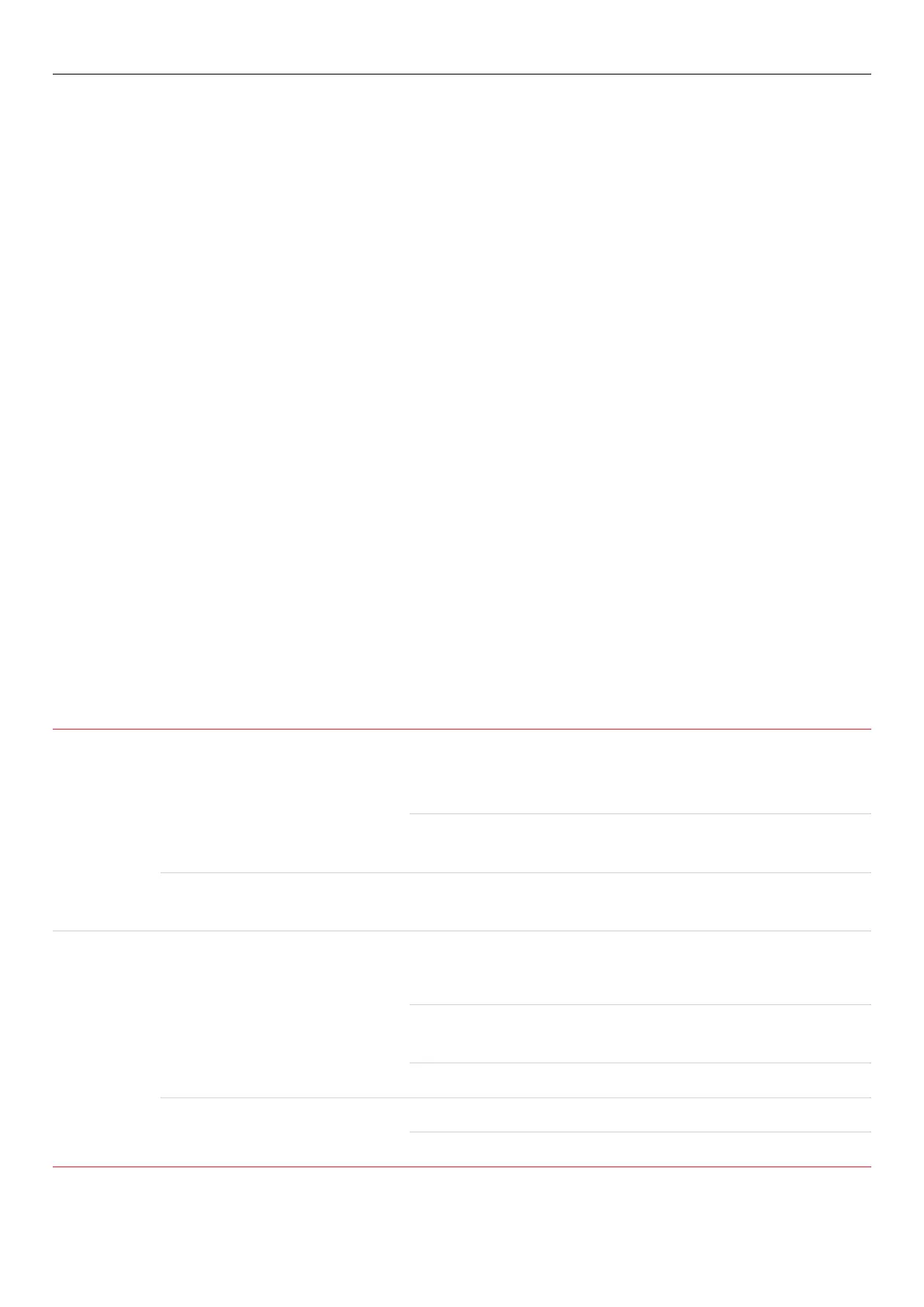

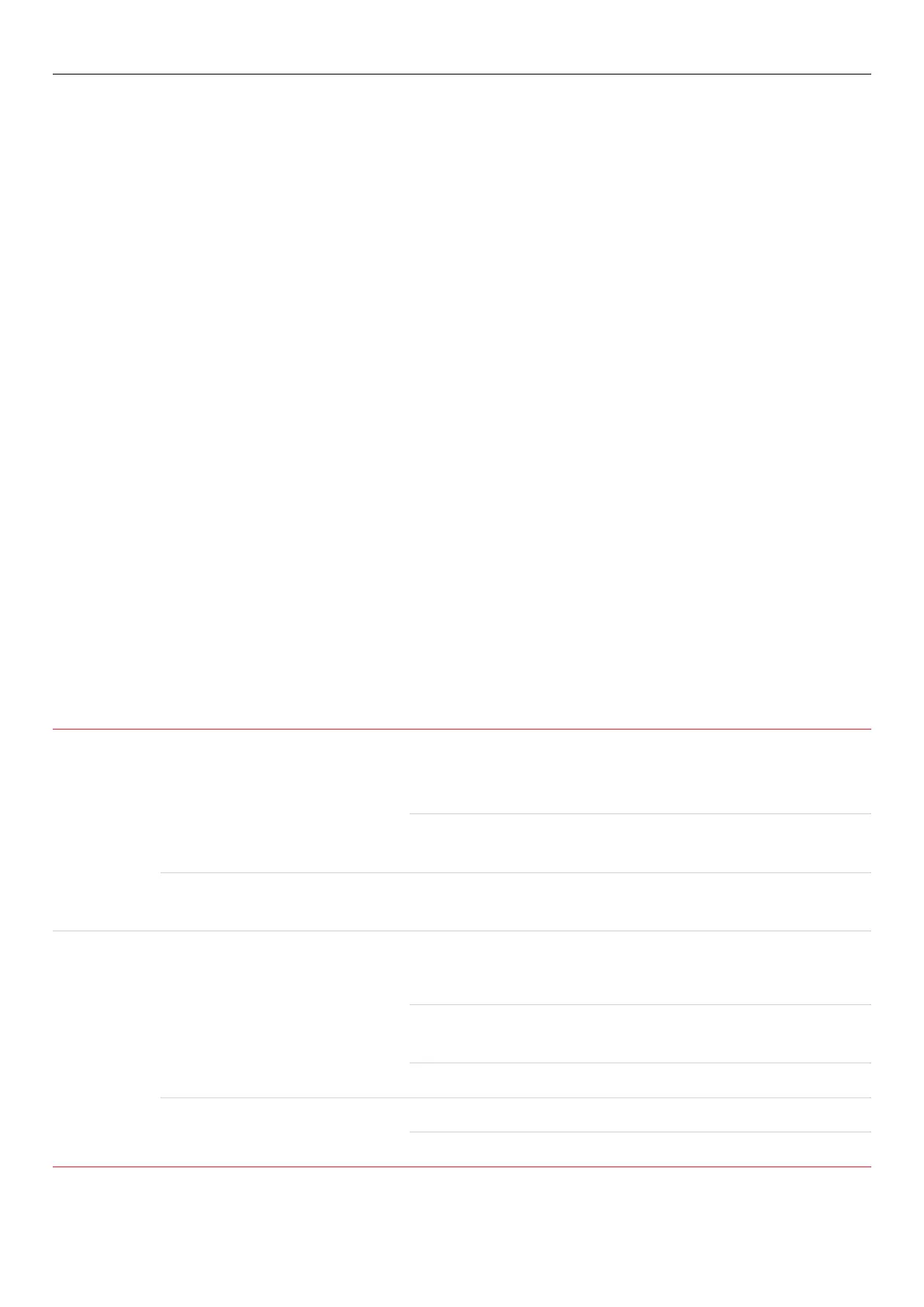

Tungsten electrodes

Base metal type

Thickness

range Desired results

Welding

current Electrode type Shielding gas Tungsten performance characteristics

Copper alloys,

Cu-NI alloys and

Nickelalloys

All General purpose DCSP 2% Thoriated

(EW-Th2)

75% Argon/

25% Helium

Best stability at medium currents. Good arc

starts

Medium tendency to spit

Medium erosion rate

2% Ceriated

(EW-Ce2)

75% Argon/

25% Helium

Low erosion rate. Wide current range. AC or DC.

No spitting. Consistent arc starts

Good stability

Only thick

sections

Increase

penetration or

travel speed

DCSP 2% Ceriated

(EW-Ce2)

75% Argon/

25% Helium

Low erosion rate. Wide current range. AC or DC.

No spitting. Consistent arc starts

Good stability

Mild Steels,

Carbon Steels,

Alloy Steels,

StainlessSteels

and Titanium

alloys

All General purpose DCSP 2% Thoriated

(EW-Th2)

75% Argon/

25% Helium

Best stability at medium currents. Good arc

starts

Medium tendency to spit

Medium erosion rate

2% Ceriated

(EW-Ce2)

75% Argon/

25% Helium

Low erosion rate. Wide current range. AC or DC.

No spitting Consistent arc starts

Good stability

2% Lanthanated

(EWG-La2)

75% Argon/

25% Helium

Lowest erosion rate. Widest current range on

DC. No spitting. Best DC arc starts and stability

Only thick

sections

Increase

penetration or

travel speed

DCSP 2% Ceriated

(EW-Ce2)

75% Argon/

25% Helium

Low erosion rate. Wide current range. No

spitting. Consistent arc starts. Good stability

2% Lanthanated

(EWG-La2)

Helium Lowest erosion rate. Highest current range. No

spitting. Best DC arc starts and stability

45BOC Smootharc Multi 180/200 Operating manual

Loading...

Loading...