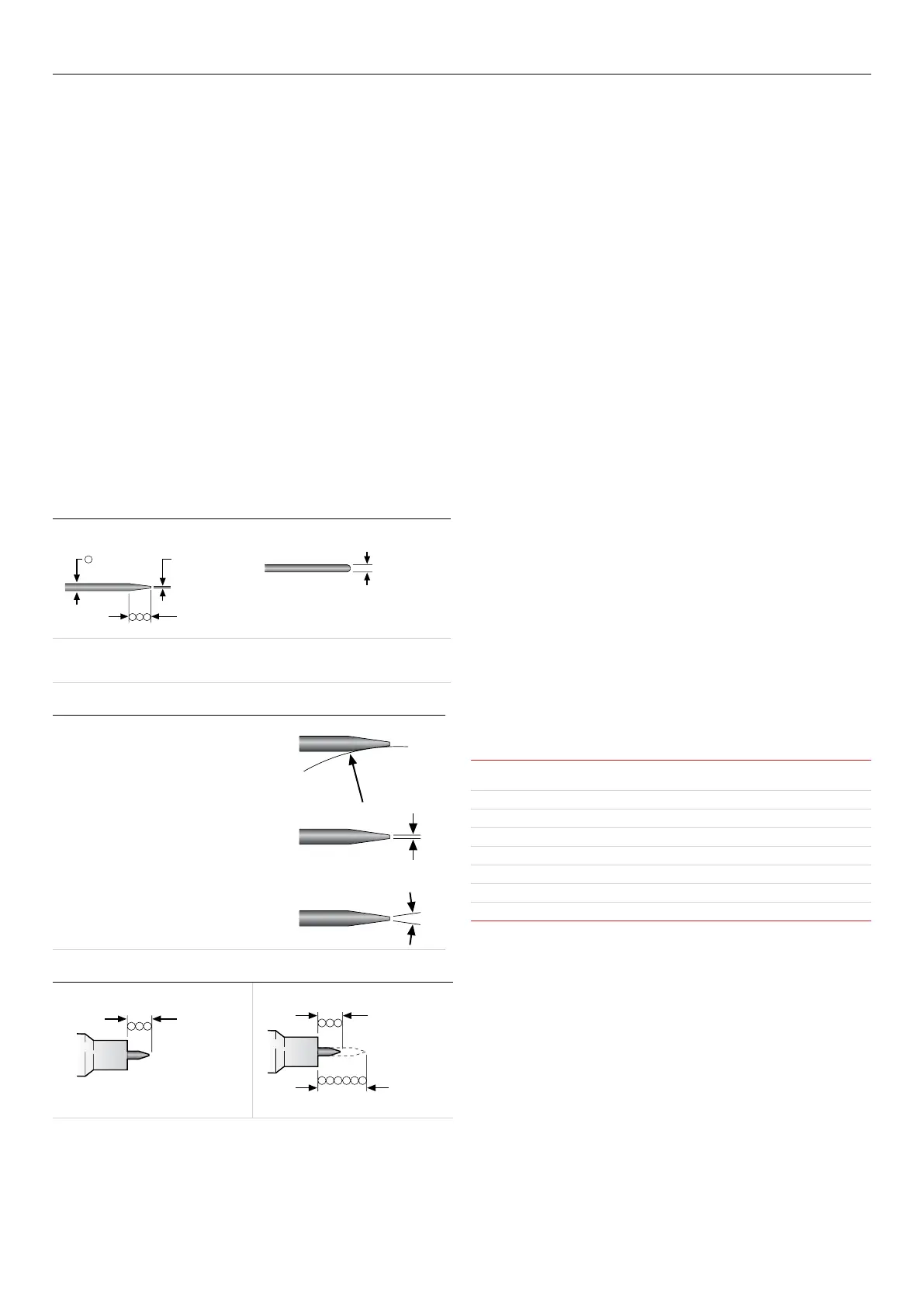

Tungsten tip preparation

= Diameter

Taper length

Flat

1/4–1/2x Dia

Max. ball

1x Dia

Ball tip by arcing on clean metal at low current DCRP (EP) then slowly

increase current to form the desired ball diameter. Return setting to AC.

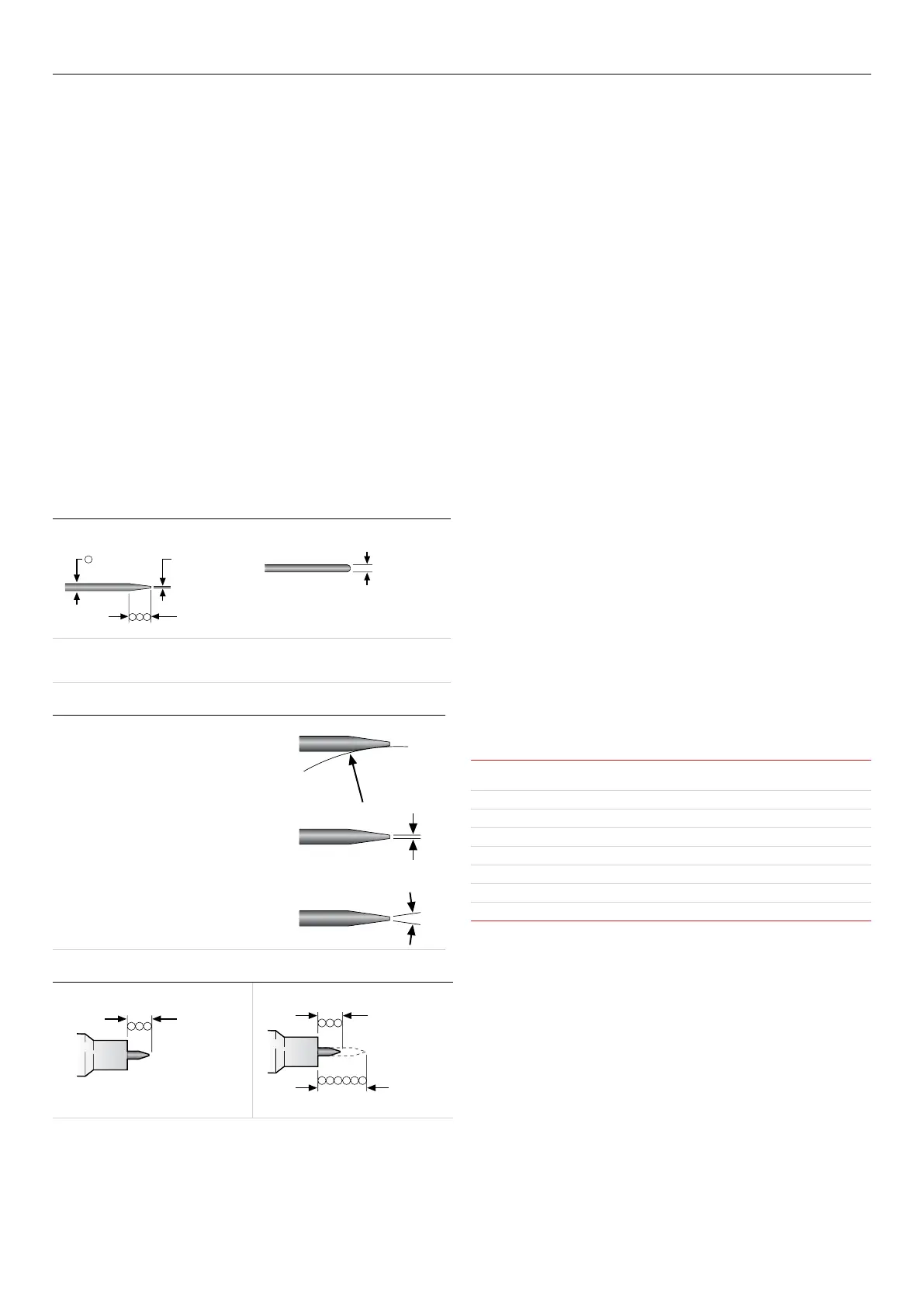

Tungsten grinding

Shape by grinding longitudinally (never

radially). Remove the sharp point to

leave a truncated point with a at

spot. Diameter of at spot determines

amperage capacity (See below). The

included angle determines weld bead

shape and size. Generally, as the

included angle increases, penetration

increases and bead width decreases.

Use a medium (60 grit or ner)

aluminium oxidewheel.

Tungsten extension

General

purpose

3x Dia

General

purpose

3x Dia

Maximum

6x Dia

(in draft free areas)

Tungsten electrode tip shapes and current ranges

Thoriated, ceriated, and lanthanated tungsten electrodes do not ball

as readily as pure or zirconiated tungsten electrodes, and as such are

typically used for DCSP welding. These electrodes maintain a ground

tip shape much better than the pure tungsten electrodes. If used on

AC, thoriated and lanthanated electrodes often spit. Regardless of the

electrode tip geometry selected, it is important that a consistent tip

conguration be used once a welding procedure is established. Changes

in electrode geometry can have a signicant inuence not only on the

weld bead width, depth of penetration, and resultant quality, but also on

the electrical characteristics of the arc. Below is a guide for electrode tip

preparation for a range of sizes with recommended current ranges.

Electrode

diameter (mm)

Diameter arc

tip (mm)

Constant

included angle,

(degrees)

Current range

(A)

1.0 0.125 12 2 – 15

1.0 0.250 20 5 – 30

1.6 0.500 25 8 – 50

1.6 0.800 30 10 – 70

2.3 0.800 35 12 – 90

2.3 1.100 45 15 – 150

3.2 1.100 60 20 – 200

3.2 1.500 90 25 – 250

46

BOC Smootharc Multi 180/200 Operating manual

Loading...

Loading...