59BOC Smootharc Multi 180/200 Operating manual

Typical defects due to faultytechnique

Manual metal arc welding, like other welding processes, has welding

procedure problems that may develop which can cause defects in the

weld. Some defects are caused by problems with the materials. Other

welding problems may not be foreseeable and may require immediate

corrective action. A poor welding technique and improper choice of

welding parameters can cause weld defects. Defects that can occur

when using the shielded metal arc welding process are slag inclusions,

wagon tracks, porosity, wormhole porosity, undercutting, lack of

fusion, overlapping, burn through, arc strikes, craters, and excessive

weld spatter. Many of these welding technique problems weaken the

weld and can cause cracking. Other problems that can occur which can

reduce the quality of the weld are arc blow, nger nailing, and improper

electrode coating moisture contents.

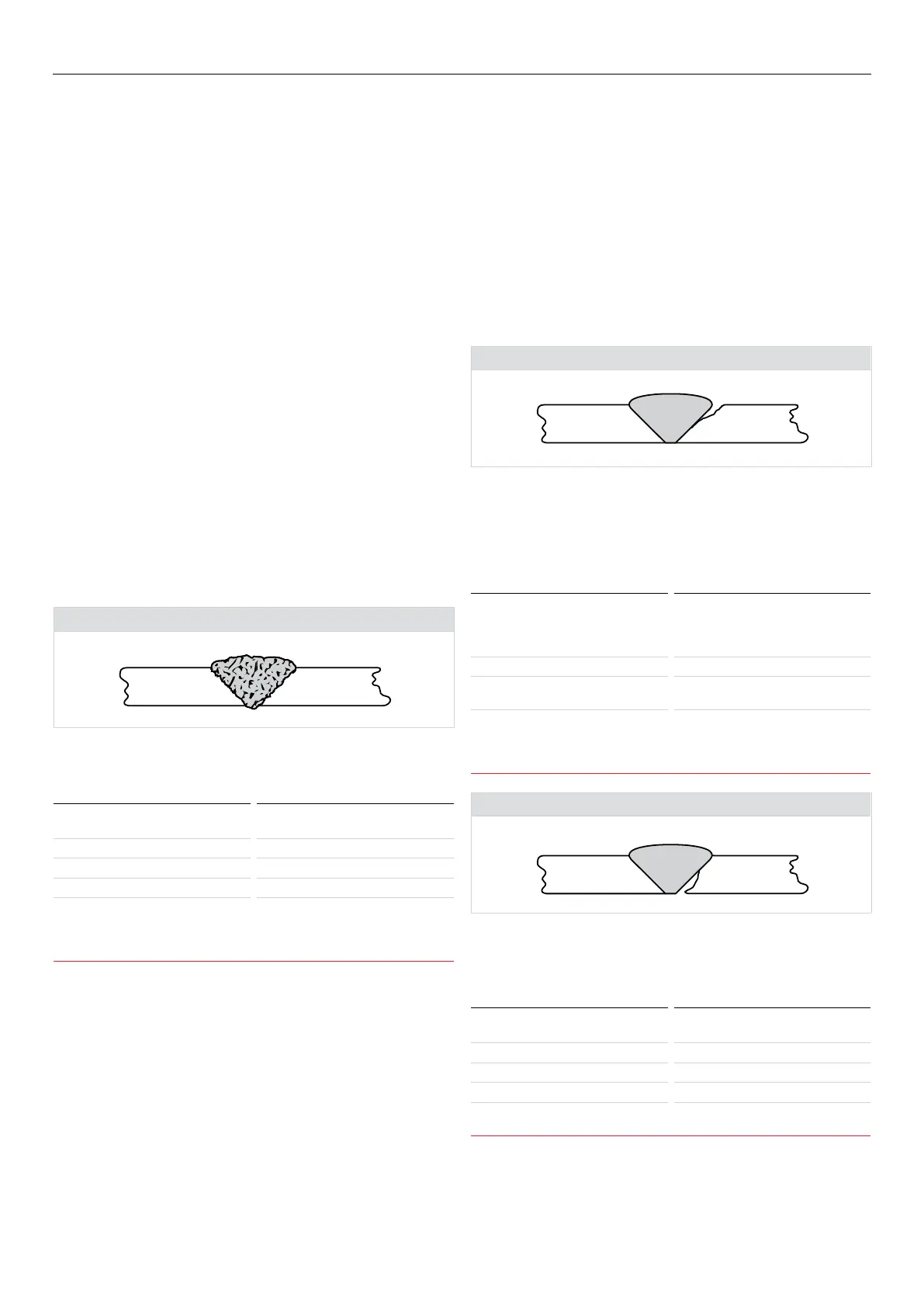

Slag Inclusions

Slag inclusions occur when slag particles are trapped inside the weld

metal which produces a weaker weld.

Cause Prevention

Erratic travel speed Uniform travel speed

Too wide a weaving motion Tighter weaving motion

Slag left on the previous weld pass Complete slag removal before welding

Too large an electrode being used Use a smaller electrode

Letting slag run ahead of the arc Keep the slag behind the arc by

shortening the arc, increasing

the travel speed, or changing the

electrode angle.

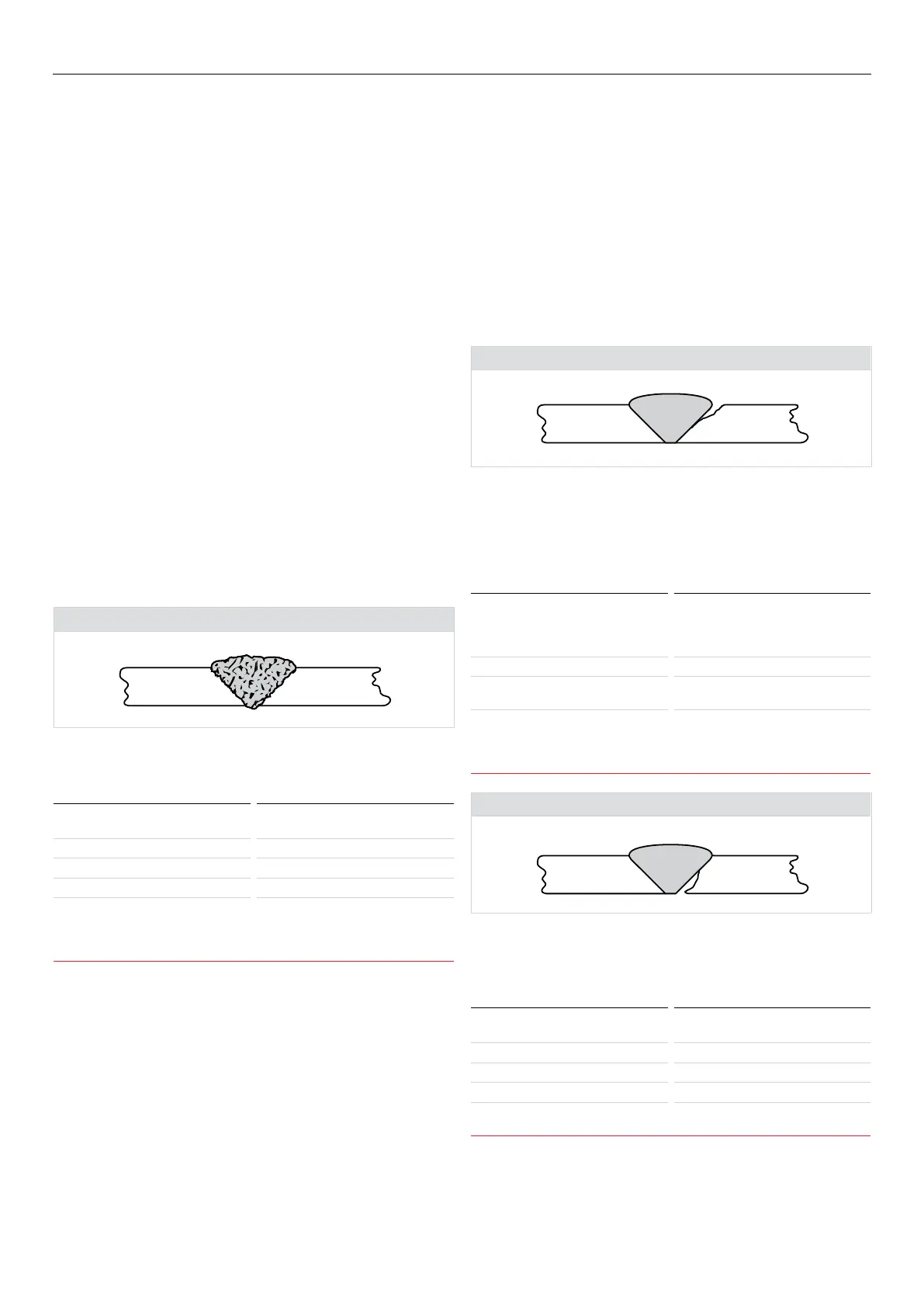

Undercutting

Undercutting is a groove melted in the base metal next to the toe or

root of a weld that is not lled by the weld metal. Undercutting causes

a weaker joint and it can cause cracking. On vertical and horizontal

welds, it can also be caused by too large an electrode size and incorrect

electrode angles.

Cause Prevention

Excessive welding current Choosing the proper welding current

for the type and size of electrode and

the welding position

Too long an arc length Holding the arc as short as possible

Slag left on the previous weld pass Pausing at each side of the weld bead

when a weaving technique isused

Excessive travel speed Using a travel speed slow enough so

that the weld metal can completely

ll all of the melted out areas of the

base metal

Lack of fusion

Lack of fusion is when the weld metal is not fused to the base metal.

This can occur between the weld metal and the base metal or between

passes in a multiple pass weld.

Cause Prevention

Excessive travel speed Reducing the travel speed

Electrode size too large Using a smaller diameter electrode

Welding current too low Increasing the welding current

Poor joint preparation Better joint preparation

Letting the weld metal get ahead of

the arc

Using a proper electrode angle.

Loading...

Loading...