14

BOC Smootharc Multi 180/200 Operating manual

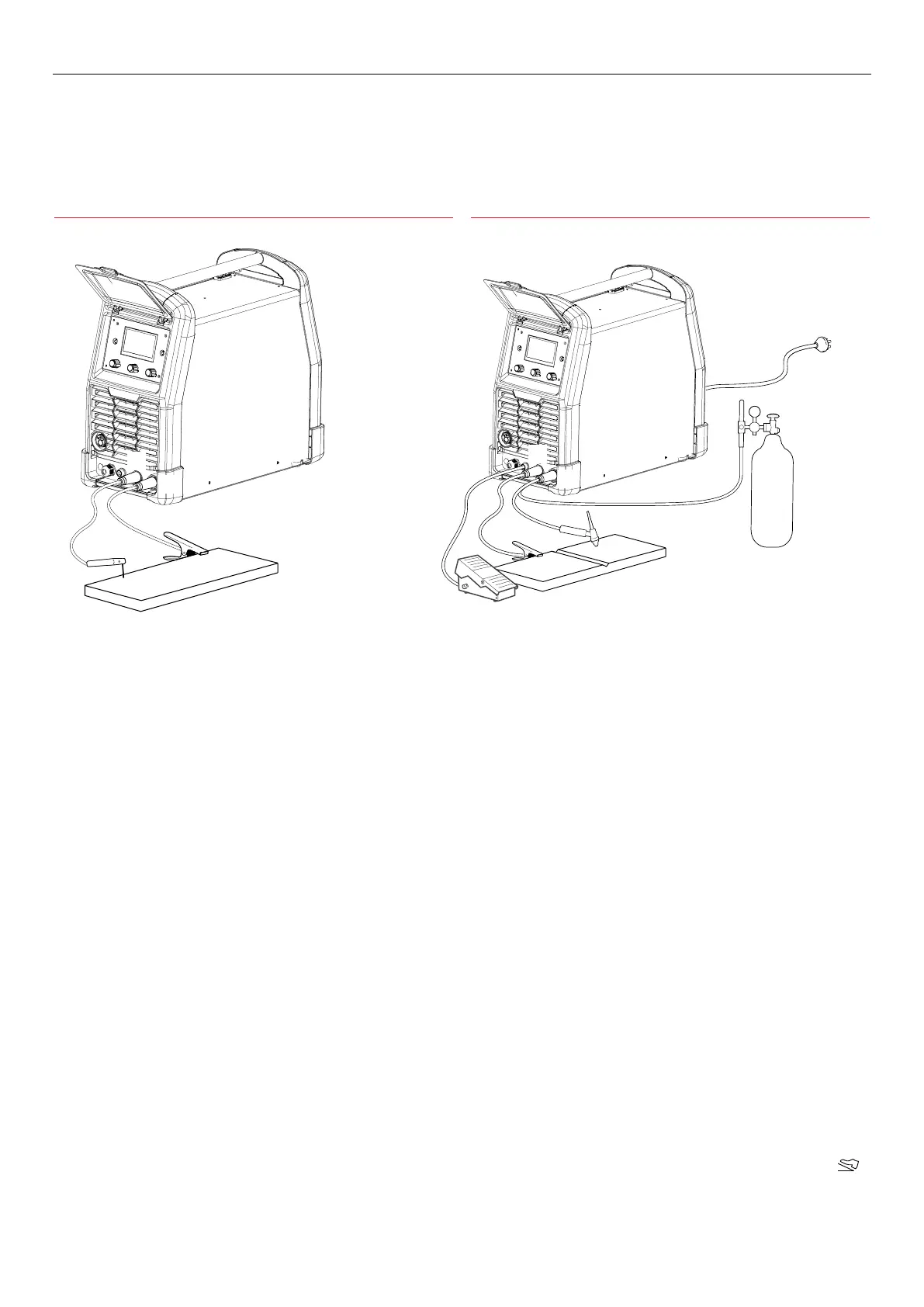

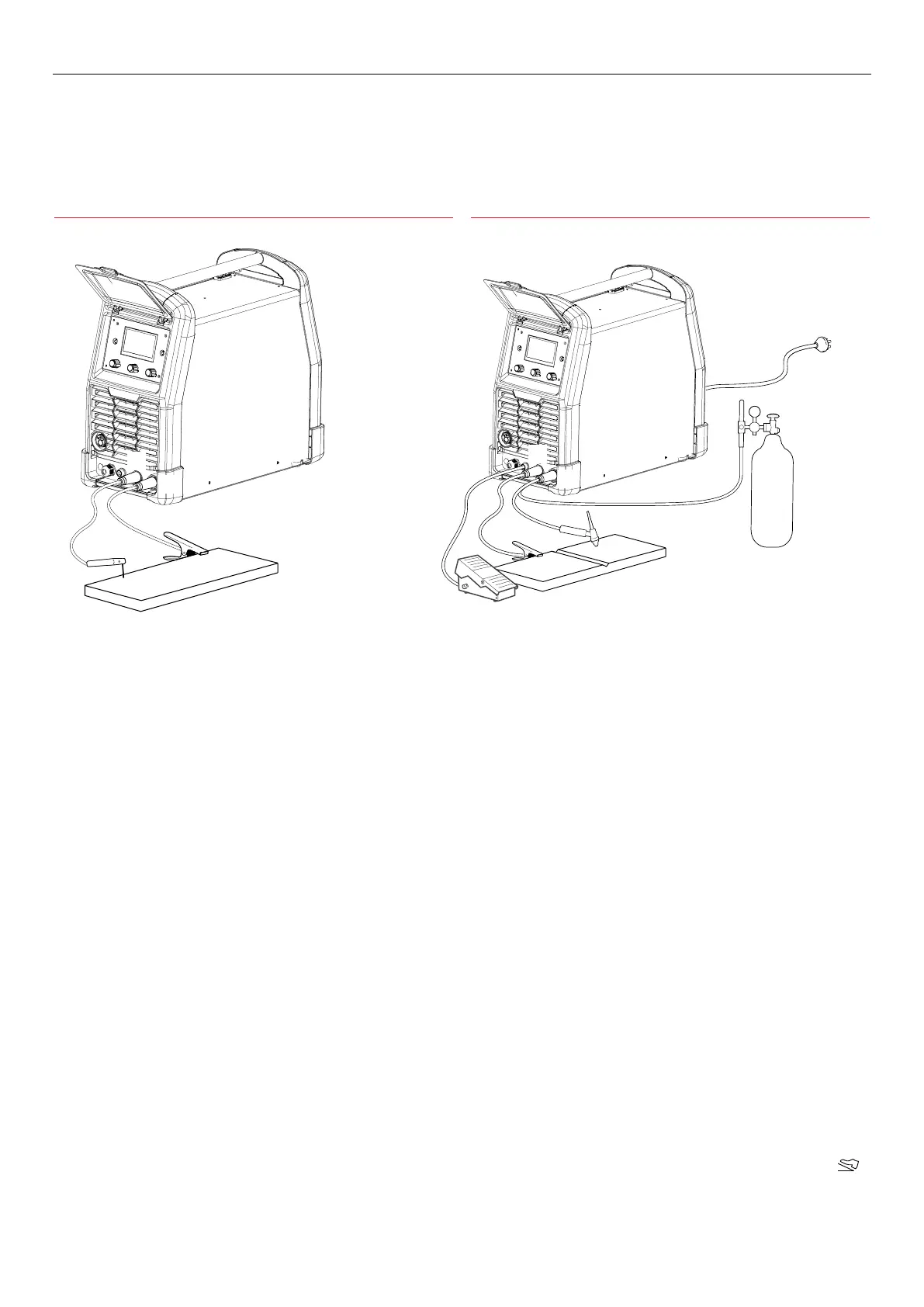

Installation for TIG setupInstallation for MMA process

MMA

1. Connect the [C] electrode holder to the [13] positive (+) terminal of

the machine and fasten it clockwise for DCEP.

2. Connect the [E] work return lead into the [14] negative (-) terminal

of the machine and fasten it clockwise (DCEP).

Please note that for manual metal arc (MMA) welding the electrode

holder can be switched to the negative pole of the welding machine if

so required by the specication of the electrode for DCEN.

TIG

1. Select correct shielding gas for the application. Connect the gas

cylinder to the regulator. Connect gas hose from TIG torch [G] to

theregulator.

2. Connect the [F] dinse plug of the TIG torch to [14] negative (-)

terminal of the front panel, and fasten it clockwise.

3. Connect [E] work return lead to [13] positive (+) terminal on the

front panel, and fasten it clockwise. Connect the clamp end to the

workpiece.

Setup using optional foot control Part No BOC/FC/LCD

The optional foot pedal switch [H], sold separately, can be used for arc

start control and welding current regulation. Welding current will switch

automatically to foot pedal control after the control plug is connected to

welder’s control cable socket. When the pedal is used, the welder begins

to work at the welding current in accordance with pressure on the pedal.

1. Plug the work return lead into output socket (+), and tighten rmly.

2. Connect work return clamp to the work piece.

3. Connect the gas cylinder to the regulator. Select correct shielding gas

for the application.

4. Connect the dinse plug of the TIG torch to negative (-) of the front

panel, and fasten it clockwise.

5. Connect securely the gas lead of the TIG torch to the gas regulator.

6. Connect the electical lead of the foot control to the control socket (

).

13

13

C

F

H

G

14

14

E

E

Loading...

Loading...