52

BOC Smootharc Multi 180/200 Operating manual

Electrode type and size

As a general rule the selection of an electrode is straight forward, in that

it is only a matter of selecting an electrode of similar composition to the

parent metal. It will be found, however, that for some metals there is a

choice of several electrodes, each of which has particular properties to

suit specic classes of work. Often, one electrode in the group will be

more suitable for general applications due to its all round qualities.

The table following shows just a few of the wide range of electrodes

available from BOC with their typical areas of application.

For example, the average welder will carry out most fabrication using

mild steel and for this material has a choice of various standard BOC

electrodes, each of which will have qualities suited to particular tasks.

For general mild steel work, however, BOC Smootharc 13 electrodes

will handle virtually all applications. BOC Smootharc 13 is suitable for

welding mild steel in all positions using AC or DC power sources. Its easy-

striking characteristics and the tolerance it has for work where t-up

and plate surfaces are not considered good, make it the most attractive

electrode of its class. Continuous development and improvement of BOC

Smootharc 13 has provided in-built operating qualities which appeals to

the beginner and experienced operator alike.

The size of the electrode is generally dependent on the thickness of the

section being welded, and the larger the section the larger the electrode

required. In the case of light sheet the electrode size used is generally

slightly larger than the work being welded. This means that if 1.5 mm

sheet is being welded, 2.0 mm diameter electrode is the recommended

size. The following table gives the recommended maximum size of

electrodes that may be used for various thicknesses of section.

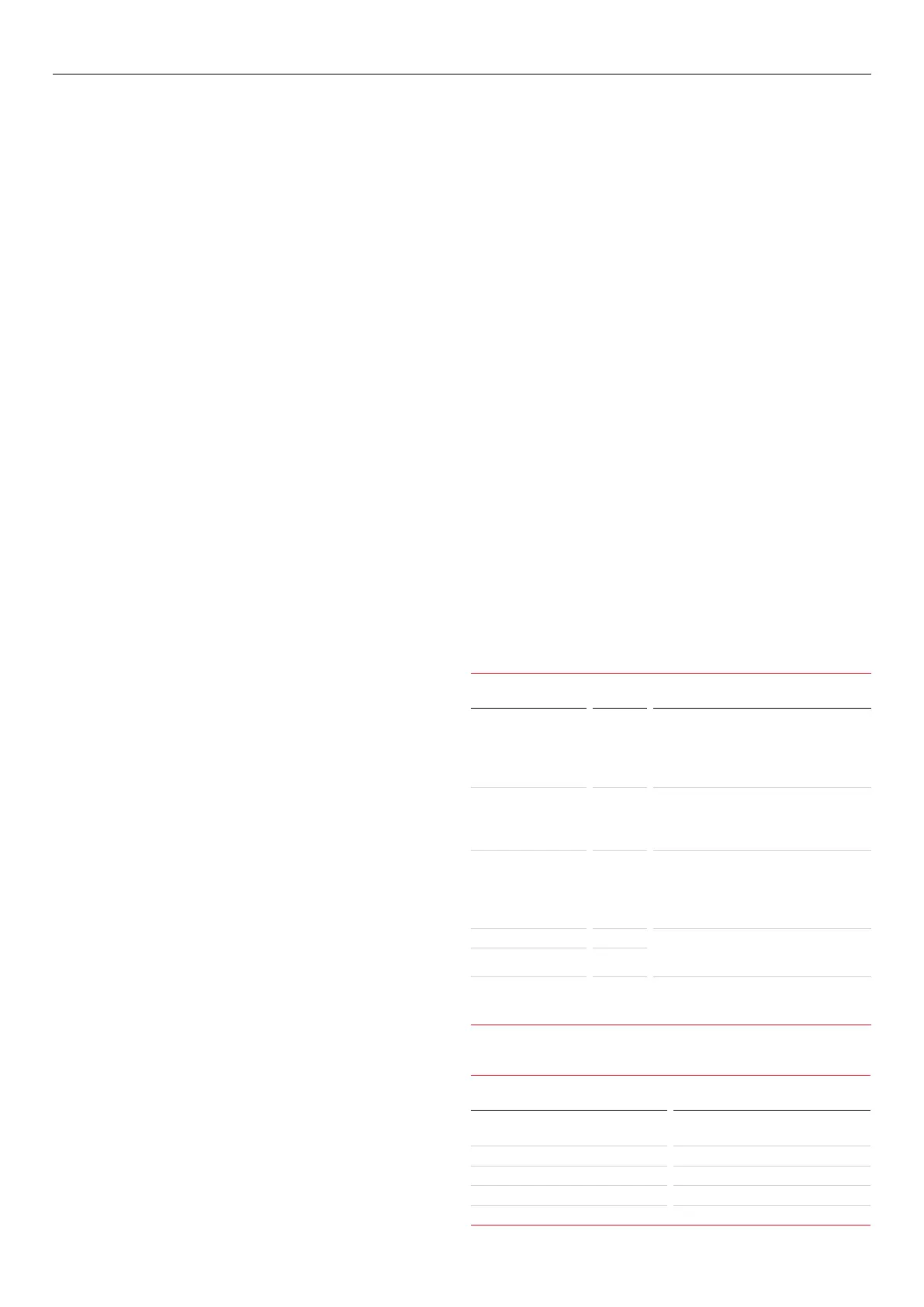

Electrodes and typical applications

Name AWS Class. Application

BOC Smootharc 13 E6013

A premium quality electrode for general

structural and sheet metal work in all

positions including vertical down using

low carbon steels

BOC Smootharc 24 E7024

An iron powder electrode for high speed

welding for H-V llets and at butt joints.

Medium to heavy structural applications

in low carbon steels

BOC Smootharc 18 E7018-1

A premium quality all positional hydrogen

controlled electrode for carbon steels in

pressure vessel applications and where

high integrity welding is required and for

free-machining steels containing sulphur

BOC Smootharc S 308L E308L

Rutile basic coated low carbon electrodes

for welding austenitic stainless steel and

dicult to weld material BOC Smootharc S 316L E316L

BOC Smootharc S 309L E309L

Rutile basic coated low carbon electrode

for welding mild steel to stainless steel

and dicult to weld material

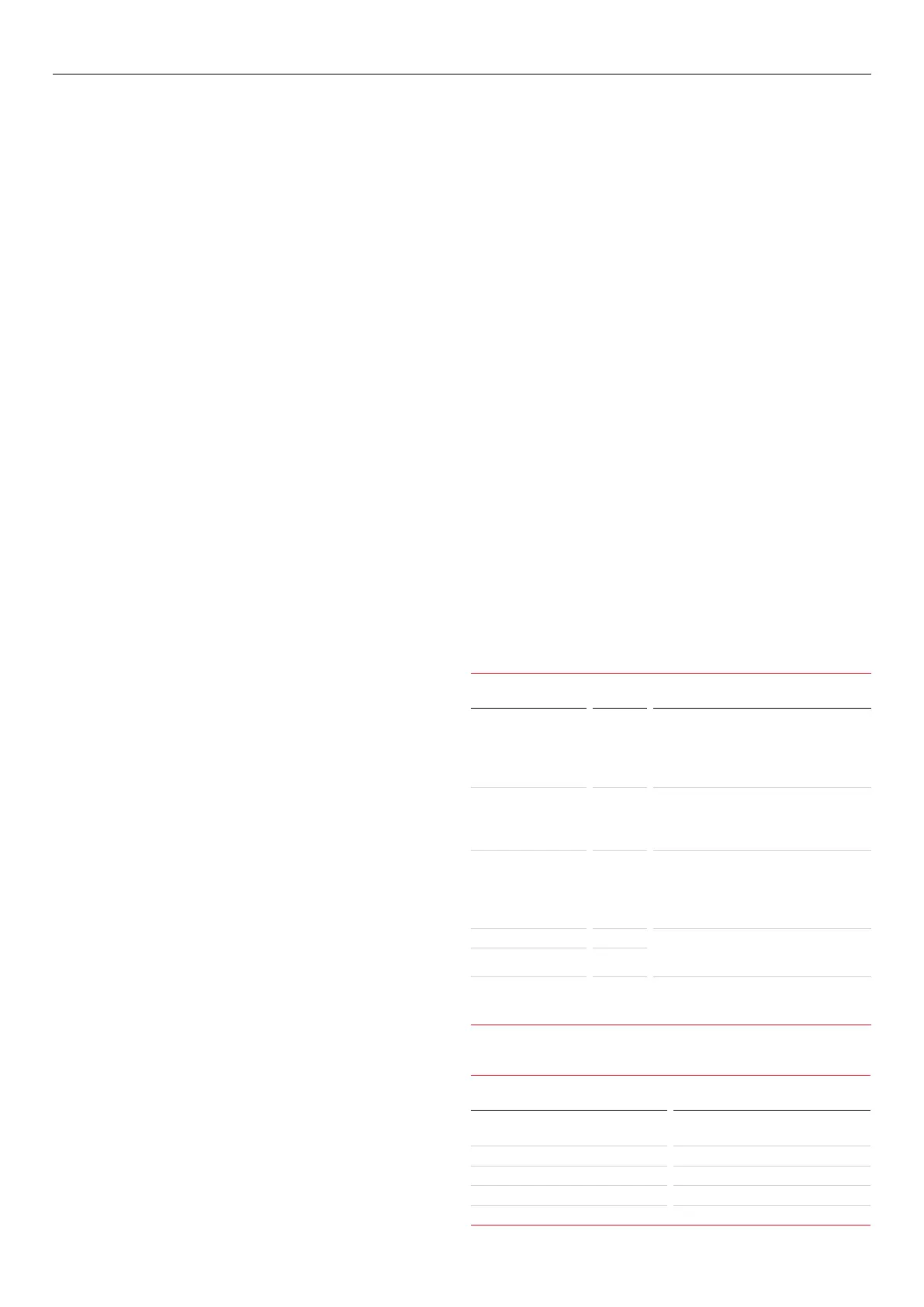

Recommended electrode sizes

Average plate or section thickness Max. recommended electrode dia.

≤1.5 mm 2.0 mm

1.5–2.0 mm 2.5 mm

2.0–5.0 mm 3.15 mm

5.0–8.0 mm 4.0 mm

≤8.0 mm 5.0 mm

Loading...

Loading...