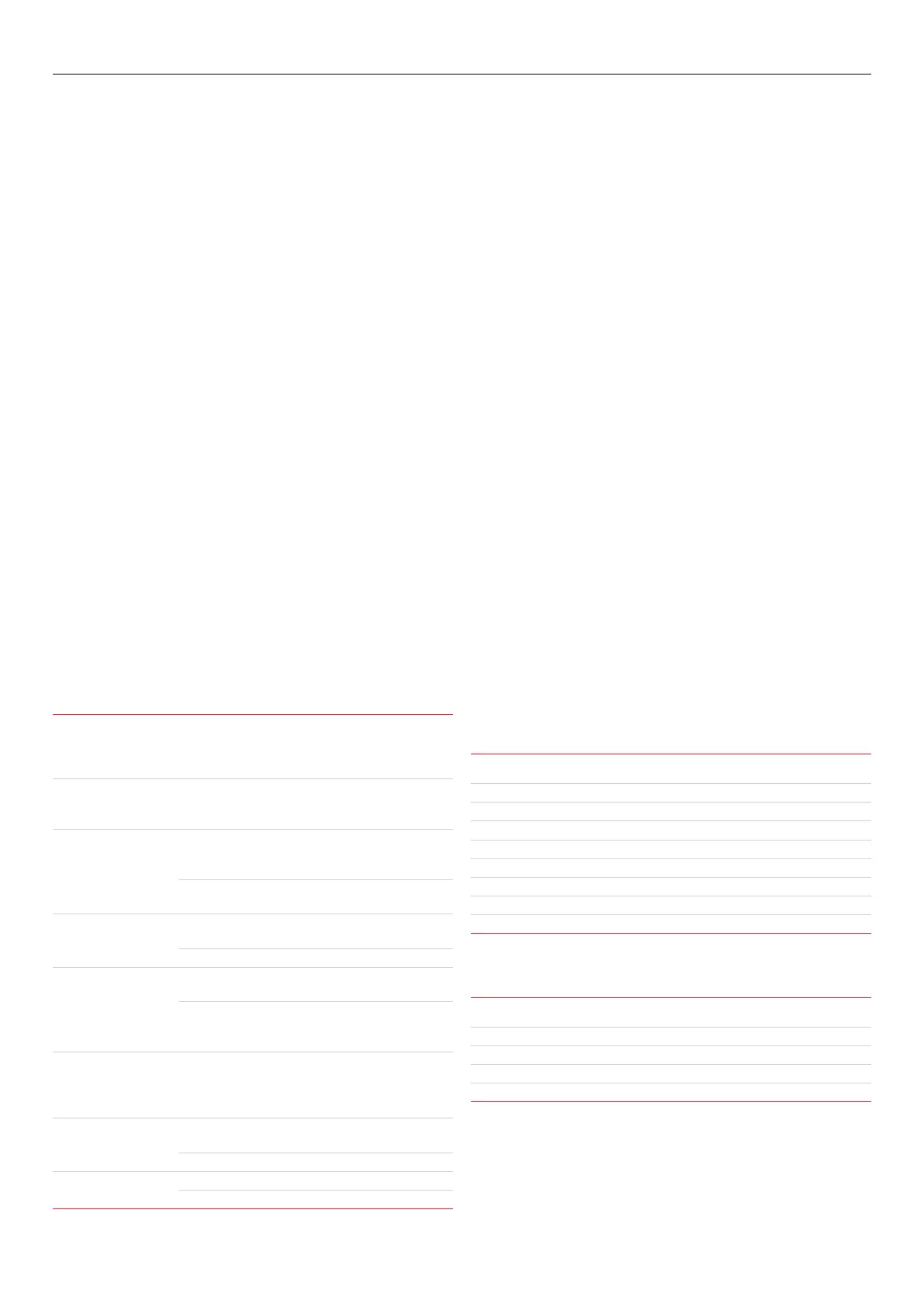

Shielding gases

Material Shielding gas Benets

Brass Argon Stable arc

Low fume

Cobalt-based alloys Argon Stable and easy to control arc

Copper-nickel

(Monel)

Argon Stable and easy to control arc

Can be used for copper-nickel

to steel

Deoxised copper Helium Increased heat input

Stable arc

Good penetration

Helium(75%)

/Argon(25%)

Stable arc

Lower penetration

Nickel alloys

(Inconel)

Argon Stable arc

Manual operation

Helium High speed automated welding

Steel Argon Stable arc

Good penetration

Helium High speed automatic welding

Deeper penetration

Small concentrated HAZ

Magnesium alloys Argon Used with continuous high

frequency AC

Good arc stability

Good cleaning action

Stainless steel Argon Good penetration

Good arc stability

Helium Deeper penetration

Titanium Argon Stable arc

Helium High speed welding

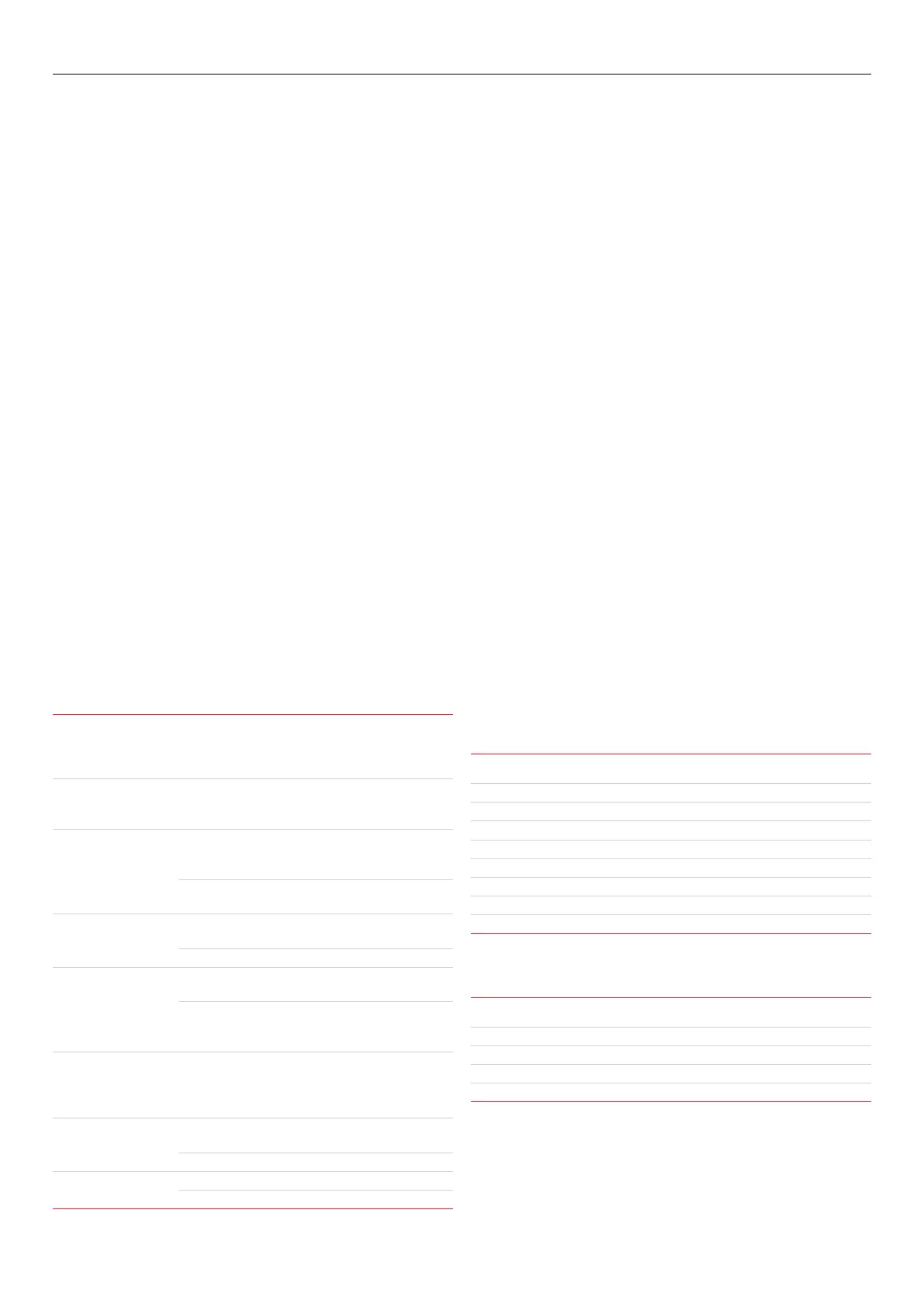

Welding wire

The following table includes the recommended welding consumable for

the most commonly weldedmaterials.

Base material BOC consumable

C-Mn and low carbon steels BOC Mild steel TIG wire

Low Alloy steels

1.25Cr/0.5Mo Comweld CrMo1

2.5Cr/1Mo Comweld CrMo2

Stainless Steel

304/304L Proll 308

316/316L Proll 316

309/309-C-Mn Proll 309

321/Stabilised grades Proll 347

Filler rod diameter (mm) Thickness of metal (mm)

2 0.5 – 2

3 2 – 5

4 5 – 8

4 or 5 8 – 12

5 or 6 12 or more

44

BOC Smootharc Multi 180/200 Operating manual

Loading...

Loading...