35BOC Smootharc Multi 180/200 Operating manual

If no external gas shield is required, then the ux ll must provide

sucient gas to protect the molten pool and to provide de-oxidisers and

nitride formers to cope with atmospheric contamination. This leaves less

scope to address performance, arc stabilisation, and process tolerance,

so these tend to suer when compared with gas shielded types.

Wire eciencies are also lower, at about 65%, in this mode of operation

than with gas-shielded wires. However, the wires do have a distinct

advantage when it comes to site work in terms of wind tolerance, as

there is no external gas shield to be disrupted.

When using self-shielded wires, external gas supply is not required and,

therefore, the gas shroud is not necessary. However, an extension nozzle

is often used to support and direct the long electrode extensions that

are needed to obtain high deposition rates.

Metal Cored Arc Welding (MCAW)

Metal-cored arc welding (MCAW) uses the heat generated by a DC

electric arc to fuse metal in the joint area, the arc being struck between

a continuously fed consumable ller wire and the workpiece, melting

both the ller wire and the workpiece in the immediate vicinity. The

entire arc area is covered by a shielding gas, which protects the molten

weld pool from the atmosphere.

As MCAW is a variant of the MIG/MAG welding process there are many

common features between the two processes, but there are also several

fundamental dierences.

As with MIG/MAG, direct current power sources with constant voltage

output characteristics are normally employed to supply the welding

current. With metal-cored wires the terminal the ller wire is connected

to depends on the specic product being used, some wires designed to

run on electrode positive, others preferring electrode negative, and some

which will run on either. The work return lead is then connected to the

opposite terminal. Electrode negative operation will usually give better

positional welding characteristics. The output characteristics of the

power source can have an eect on the quality of the weldsproduced.

The wire feed unit takes the ller wire from a spool or bulk pack, and

feeds it through the welding torch, to the arc at a predetermined and

accurately controlled speed. Normally, special knurled feed rolls are

used with metal-cored wires to assist feeding and to prevent crushing

theconsumable.

Unlike MIG/MAG, which uses a solid consumable ller wire, the

consumable used in MCAW is of tubular construction, an outer metal

sheath being lled entirely with metal powder except for a small amount

of non-metallic compounds. These are added to provide some arc

stability and de-oxidation.

MCAW consumables always require an auxiliary gas shield in the

same way that solid MIG/MAG wires do. Wires are normally designed

to operate in argon-carbon dioxide or argon-carbon dioxide-oxygen

mixtures or carbon dioxide. Argon rich mixtures tend to produce lower

fume levels than carbon dioxide.

As with MIG/MAG, the consumable ller wire and the shielding gas are

directed into the arc area by the welding torch. In the head of the torch,

the welding current is transferred to the wire by means of a copper alloy

contact tip, and a gas diuser distributes the shielding gas evenly around

a shroud which then allows the gas to ow over the weld area. The

position of the contact tip relative to the gas shroud may be adjusted to

limit the minimum electrode extension.

Modes of metal transfer with MCAW are very similar to those obtained

in MIG/MAG welding, the process being operable in both ‘dip transfer’

and ‘spray transfer’ modes. Metal-cored wires may also be used in

pulse transfer mode at low mean currents, but this has not been

widelyexploited.

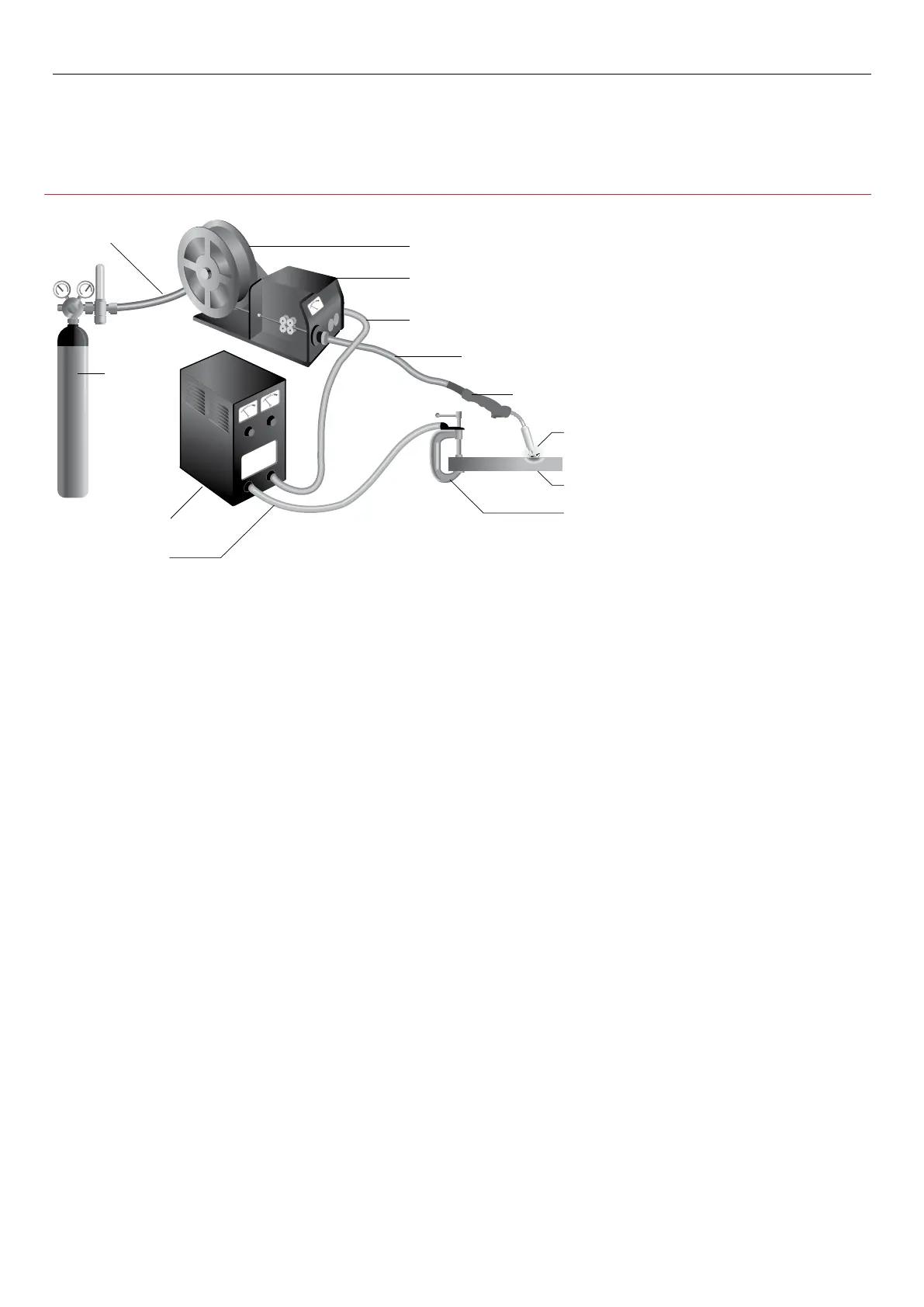

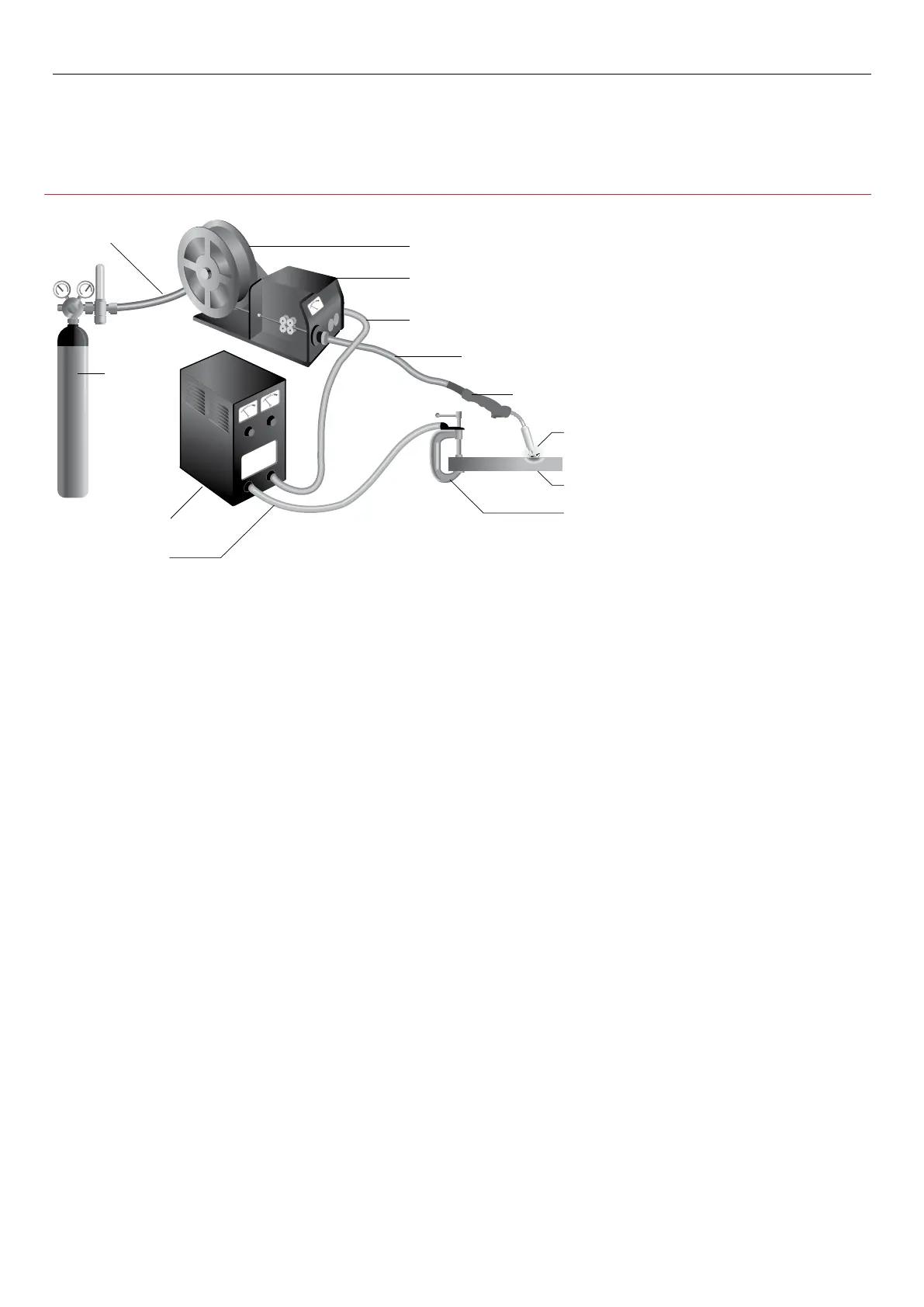

Gas hose

Gas cylinder

Power source

Return cable

Continuous wire

Wire feed unit

Power cable

Torch conduit

Welding torch

Workpiece

Arc

Earth clamp

Process schematic diagram for MIG/MAG, FCAW and MCAW

Loading...

Loading...