38

BOC Smootharc Multi 180/200 Operating manual

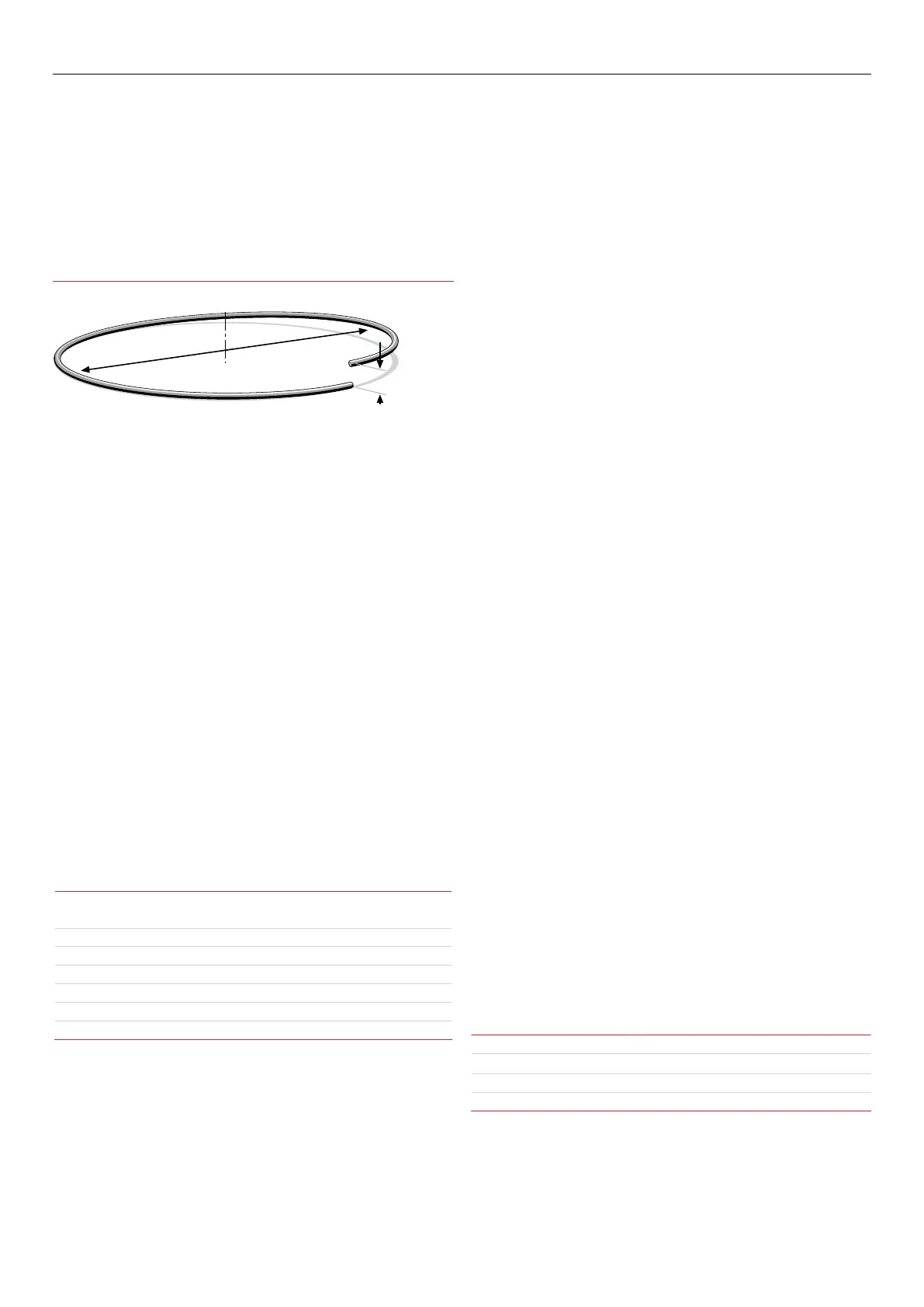

Cast

Helix

Cast – Diameter of the circle

Helix – Vertical height

Cast and Helix

Consumables

Chemical composition

As a general rule the selection of a wire is straightforward, in that it

is only a matter of selecting an electrode of similar composition to

the parent material. It will be found, however, that there are certain

applications that electrodes will be selected on the basis of its

mechanical properties or level of residual hydrogen in the weldmetal.

Solid MIG/MAG wires are all considered to be of the 'low Hydrogen type'

consumables.

The following table gives a general overview of the selection of some of

the BOC range of MIG/MAG wires for the most common materials.

Common materials welded with BOC MIG wire

AS2074 C1,C2,C3,C4-1,C4-2,C5,C6 BOC Mild Steel MIG Wire

AS/NZS1163 C250 BOC Mild Steel MIG Wire

AS/NZS3678 200,250,300 BOC Mild Steel MIG Wire

ASTM A36,A106 BOC Mild Steel MIG Wire

Stainless Steel Grade 304/L BOC Stainless Steel 308LSi

Stainless Steel Grade 309 BOC Stainless Steel 309LSi

Stainless Steel Grade 316/L BOC Stainless Steel 316LSi

Surface condition

The welding wire must be free from any surface contamination including

mechanical damage such as scratch marks.

A simple test for checking the surface condition is to run the wire

through a cloth that has been dampened with acetone for 20 secs.

If a black residue is found on the cloth the surface of the wire is not

properlycleaned.

Cast and helix

The cast and helix of the wire has a major inuence on the feedability of

MIG/MAG wire.

If the cast is too large the wire will move in an upward direction from the

tip when welding and if too small the wire will dip down from the tip.

The result of this is excessive tip wear and increased wear in the liners.

If the helix is too large the wire will leave the tip with a corkscrew eect.

Power sources

Power sources for MIG/MAG welding is selected on a number of dierent

criteria, including:

→ Maximum output of the machine

→ Duty cycle

→ Output control (voltage selection, wire feed speed control)

→ Portability

The following table gives an indication of the operating amperage for

dierent size wires.

Wire size Amperage range (A)

0.8 mm

60–180

0.9 mm 70–250

1.0 mm 90–280

1.2 mm 120–340

Loading...

Loading...