37BOC Smootharc Multi 180/200 Operating manual

Spray transfer

In spray transfer, metal is projected by an electromagnetic force from

the wire tip in the form of a continuous stream of discrete droplets

approximately the same size as the wire diameter. High deposition

rates are possible and weld appearance and reliability are good. Most

metals can be welded, but the technique is limited generally to plate

thicknesses greater than 6 mm. Spray transfer, due to the tendency of

the large weld pool to spill over, cannot normally be used for positional

welding. The main exception is aluminium and its alloys where, primarily

because of its low density and high thermal conductivity, spray transfer

in position can be carried out.

The current ows continuously because of the high voltage maintaining

a long arc and short-circuiting cannot take place. It occurs best with

argon-based gases.

In solid wire MIG/MAG, as the current is increased, dip transfer passes

into spray transfer via a transitional globular transfer mode. With metal-

cored wires there is virtually a direct transition from dip transfer to spray

transfer as the current is increased.

For metal cored wire spray transfer occurs as the current density

increases and an arc is formed at the end of the ller wire, producing

a stream of small metal droplets. Often the outside sheath of the wire

will melt rst and the powder in the centre ows as a stream of smaller

droplet into the weld pool. This eect seems to give much better transfer

of alloying elements into the weld.

In spray transfer, as the current density increases, an arc is formed at

the end of the ller wire, producing a stream of small metal droplets. In

solid wire MIG/MAG this transfer mode occurs at higher currents. Flux-

cored wires do not achieve a completely true spray transfer mode but a

transfer mode that is almost true spray may occur at higher currents and

can occur at relatively low currents depending on the composition of

theux.

Rutile ux-cored wires will operate in this almost-spray transfer mode, at

all practicable current levels. They are also able to operate in this mode

for positional welding too. Basic ux-cored and self-shielded ux-cored

wires do not operate in anything approaching true spray transfer mode.

Pulsed transfer

Pulsed arc welding is a controlled method of spray transfer, using

currents lower than those possible with the spray transfer technique,

thereby extending the applications of MIG/MAG welding into the range

of material thickness where dip transfer is not entirely suitable. The

pulsed arc equipment eectively combines two power sources into one

integrated unit. One side of the power source supplies a background

current which keeps the tip of the wire molten. The other side produces

pulses of a higher current that detach and accelerate the droplets of

metal into the weld pool. The transfer frequency of these droplets is

regulated primarily by the relationship between the two currents. Pulsed

arc welding occurs between ±50-220A, 23–35 arc volts and only with

argon and argon-based gases. It enables welding to be carried out in

allpositions.

Large droplet

Splatter

Workpiece

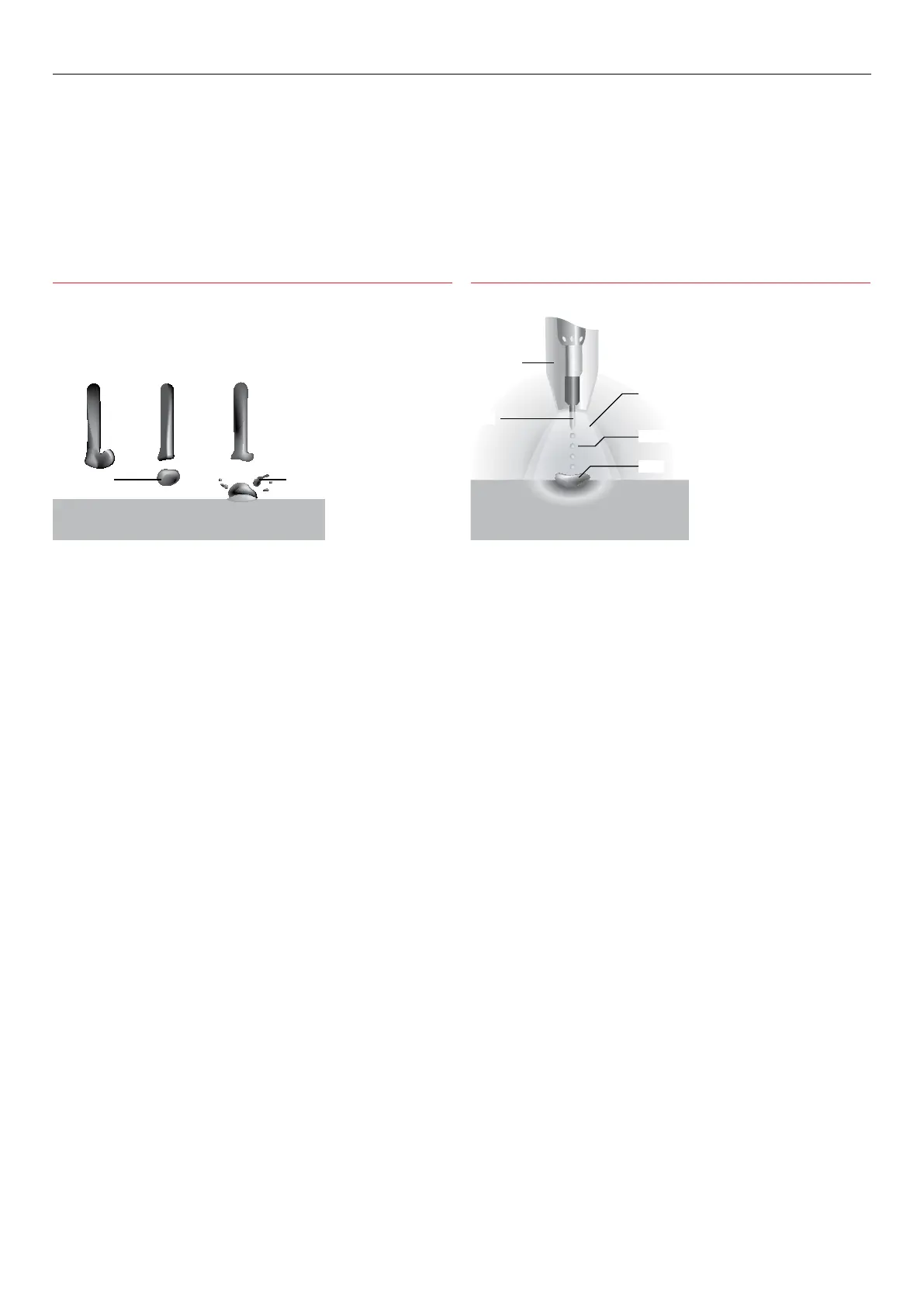

Gas shroud

Wire

Shielding gas

Droplets

Weld

Workpiece

Schematic of globular transfer Schematic of spray transfer

Loading...

Loading...