Techniques for successful TIG welding

TIG welding techniques

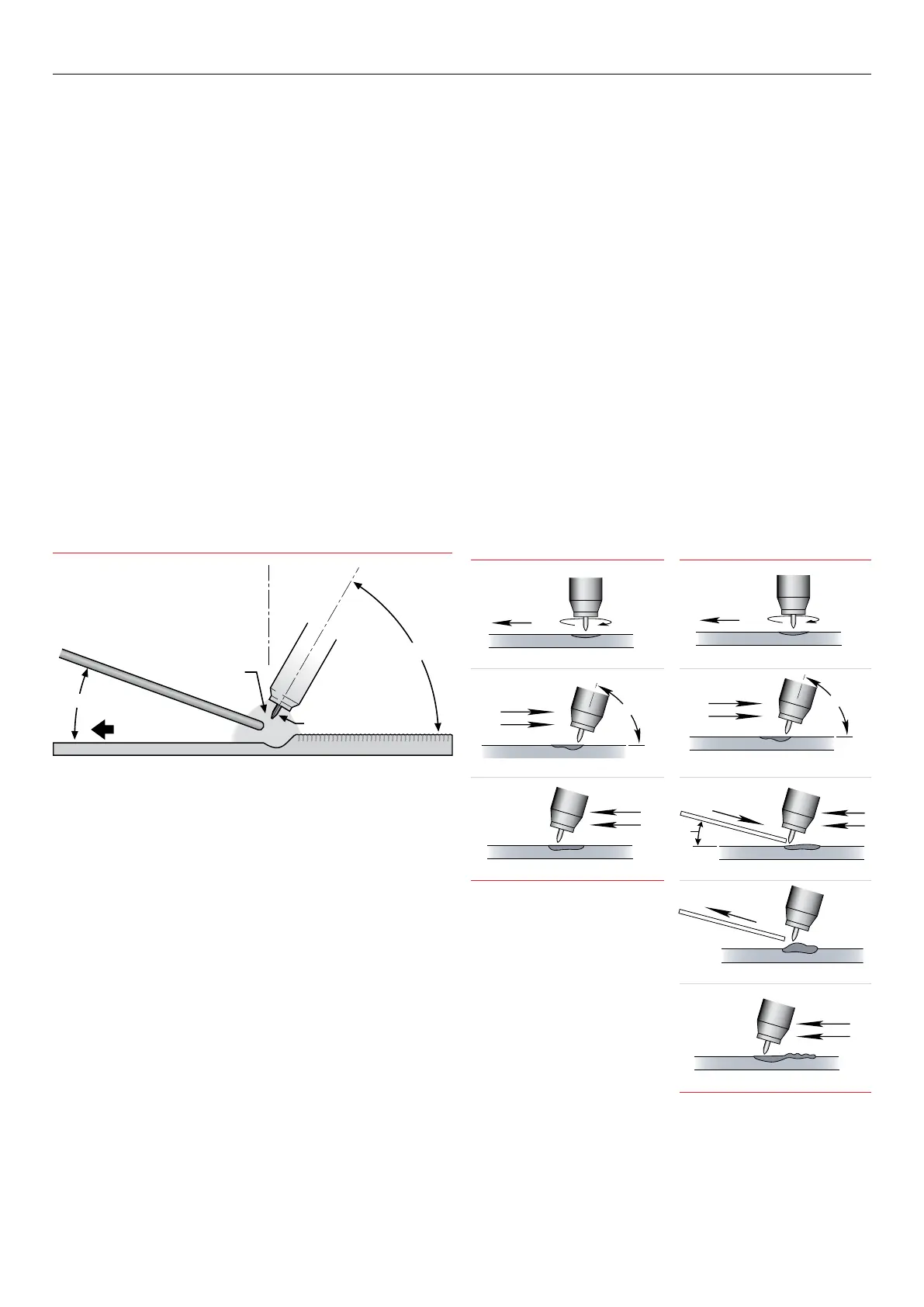

60–75°

15–30°

Nozzle

Direction of travel

Welding Rod

Shield gas

Vertical

Tungsten electrode

The suggested electrode and welding rod angles for welding a bead on

plate are shown above. The same angles are used when making a butt

weld. The torch is held 60–75° from the metal surface. This is the same

as holding the torch 15–30° from the vertical.

Take special note that the rod is in the shielding gas during the

weldingprocess.

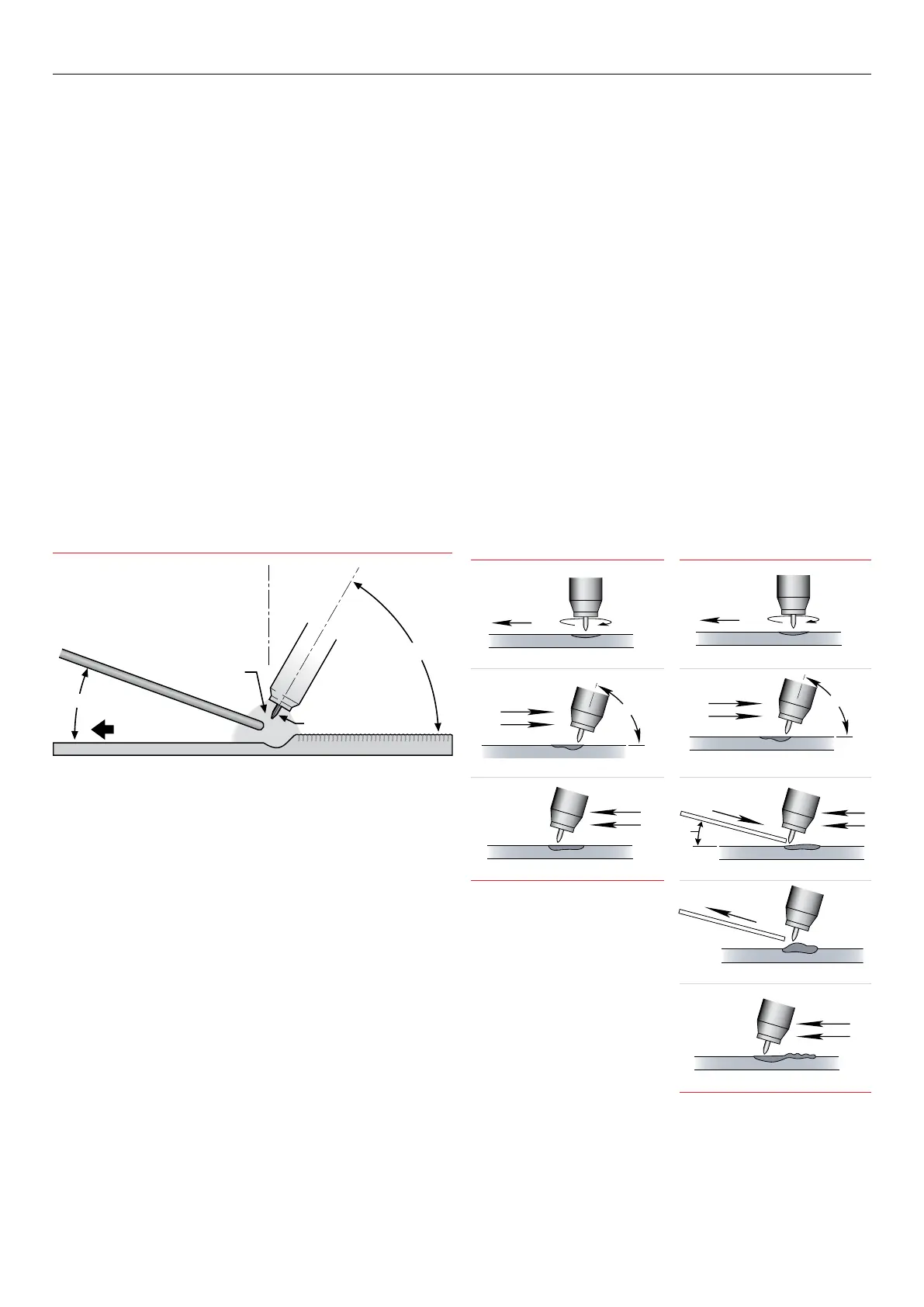

Torch movement during welding

Tungsten without ller rod Tungsten with ller rod

Welding

direction

Form pool

Welding

direction

Form pool

75°

Tilt torch

75°

Tilt torch

Move torch to front of pool. Repeat.

15°

Add ller metal

Remove rod

Move torch to front of pool. Repeat.

47BOC Smootharc Multi 180/200 Operating manual

Loading...

Loading...