40

BOC Smootharc Multi 180/200 Operating manual

Correct application techniques

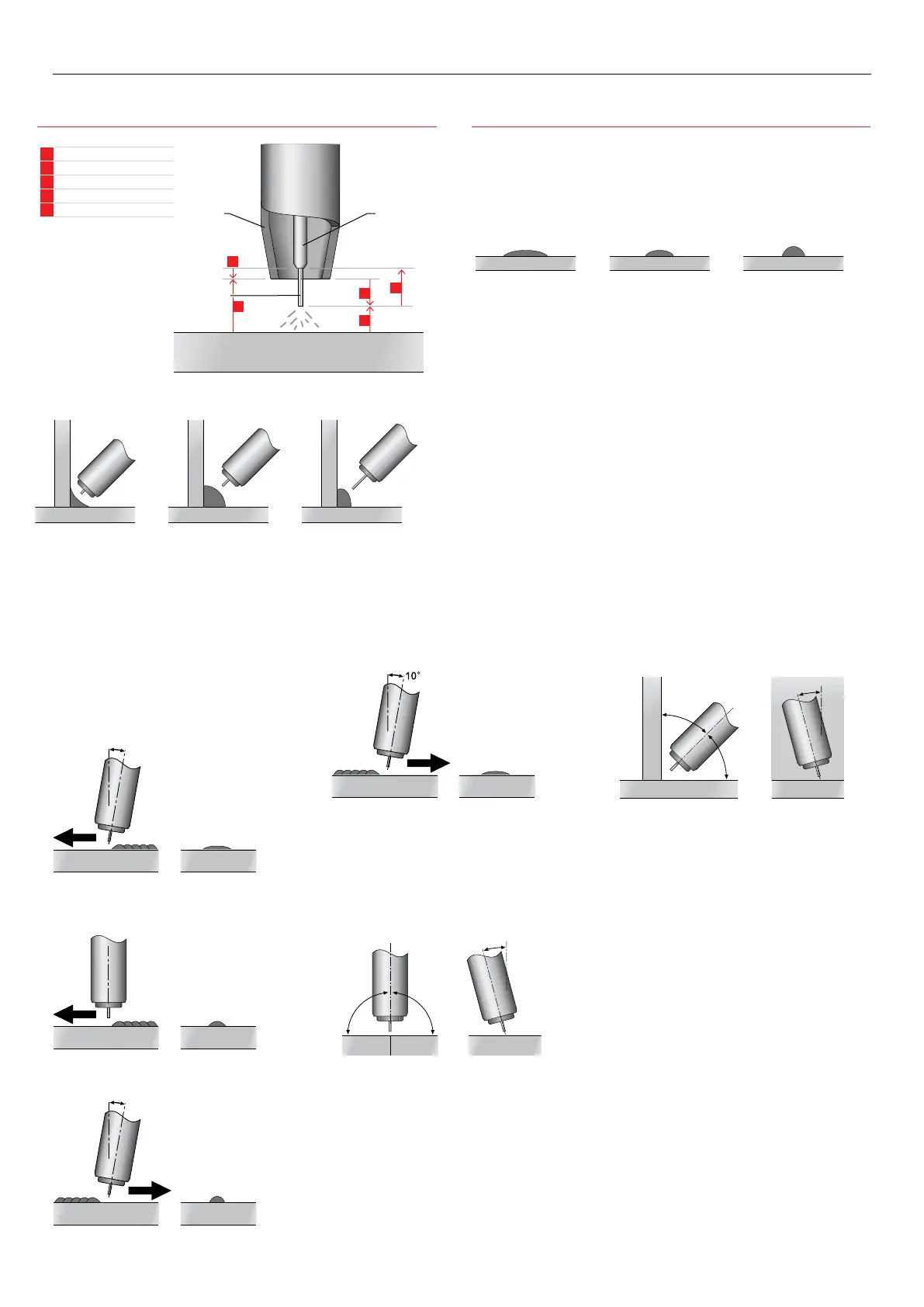

Electrical stickout

Short Normal Long

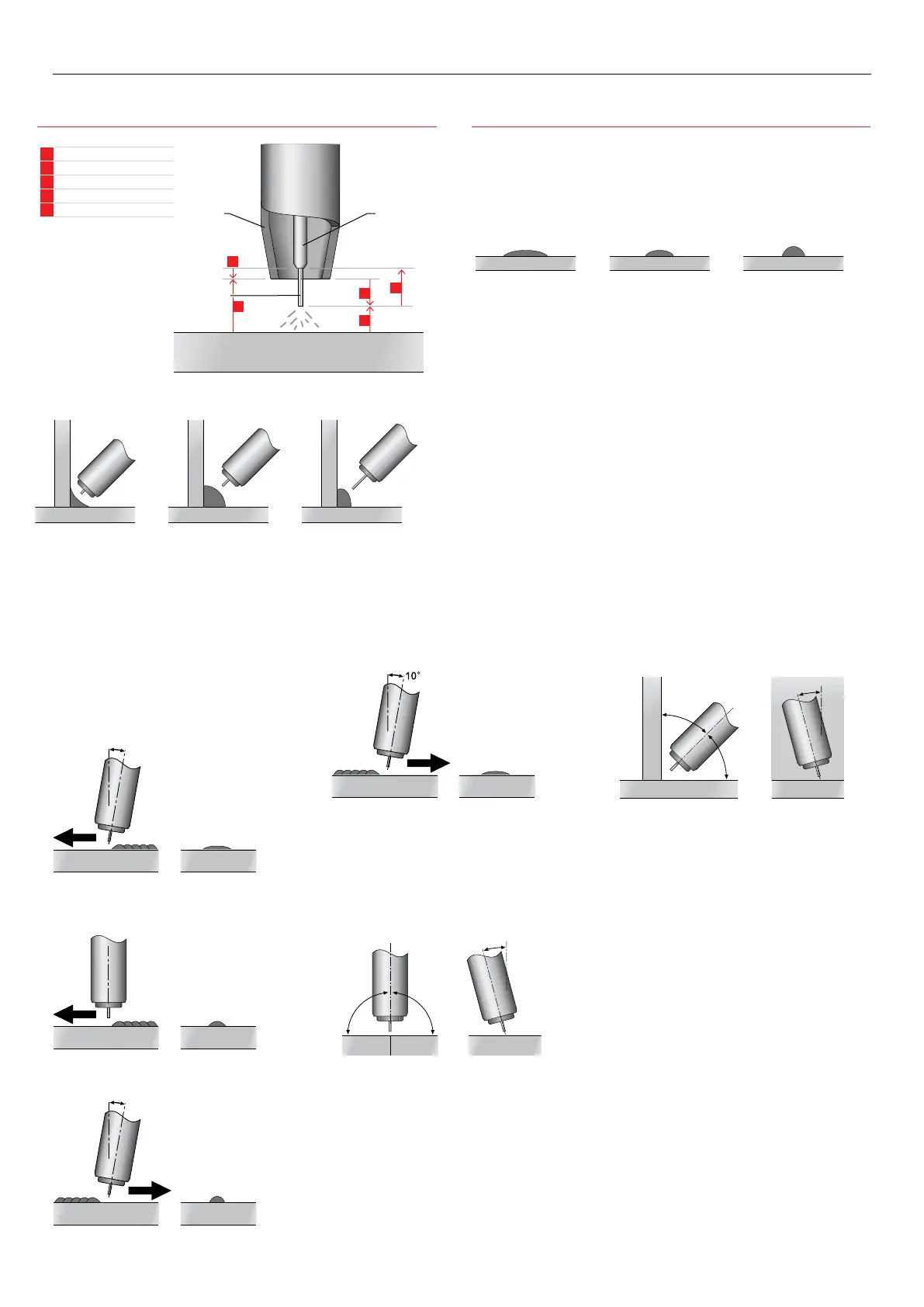

Travel speed

Slow Normal Fast

MIG/MAG

MIG/MAG welding with solid wires takes place

normally with a push technique. The welding

torch is tilted at an angle of 10° towards the

direction of welding. (Push technique)

10°

The inuence of changing the torch angle and

the welding direction on the weld bead prole

can be seen below.

Torch perpendicular to workpiece narrow bead

width with increased reinforcement.

10°

Torch positioned at a drag angle of 10° narrow

bead with excessive reinforcement.

Flux cored

Flux cored welding with cored wires takes

place normally with the drag technique. The

welding torch is tilted at an angle of 10° away

from the direction of welding. For all other

applications the torch angle remains the same.

Butt welds

90° 90°

0–15°

When welding butt welds the torch should

be positioned within the centre of the groove

and tilted at an angle of ±15° from the vertical

plane. Welding is still performed in the push

technique.

Fillet welds

0–15°

45°

45°

When welding llet welds the torch should be

positioned at an angle of 45° from the bottom

plate with the wire pointing into the llet

corner. Welding is still performed in the push

technique.

Electrical stickout

The electrical stickout is the distance

between the end of the contact tip and

the end of the wire. An increase in the

electrical stickout results in an increase in the

electrical resistance. The resultant increase

in temperature has a positive inuence in

the melt-o rate of the wire that will have an

inuence on the weldbead prole.

Inuence of the change in electrical stickout

length on the weldbeadprole.

Travel speed

The travel speed will have an inuence on the

weldbead prole and the reinforcement height.

If the travel speed is too slow a wide weldbead

with excessive rollover will result. Contrary if

the travel speed is too high a narrow weldbead

with excessive reinforcement will result.

C

Contact Tube Setback

S

Stando Distance

V

Visible Stickout

A

Arc length

E

Electrical Stickout

A

S

C

V

E

Contact Tube

Gas Nozzle

Consumable

Electrode

Workpiece

Loading...

Loading...