34

BOC Smootharc Multi 180/200 Operating manual

In terms of gas shielding, there are two dierent ways in which this may

be achieved with the FCAW process.

→ Additional gas-shielding supplied from an external source, such as a

gas cylinder

→ Production of a shielding gas by decomposition of uxing agents

within the wire, self-shielding

Gas shielded wires are available with either a basic or rutile ux ll,

while self-shielded wires have a broadly basic-type ux ll. The ux

ll dictates the way the wire performs, the properties obtainable, and

suitable applications.

Gas-shielded operation

Many cored wire consumables require an auxiliary gas shield in the same

way that solid wire MIG/MAG consumables do. These types of wire are

generally referred to as ‘gas-shielded’.

Using an auxiliary gas shield enables the wire designer to concentrate

on the performance characteristics, process tolerance, positional

capabilities, and mechanical properties of the products.

In a ux cored wire the metal sheath is generally thinner than that of

a self-shielded wire. The area of this metal sheath surrounding the ux

cored wire is much smaller than that of a solid MIG/MAG wire. This

means that the electrical resistance within the ux cored wire is higher

than with solid MIG/MAG wires and it is this higher electrical resistance

that gives this type of wire some of its novel operating properties.

One often quoted property of uxed cored wires are their higher

deposition rates than solid MIG/MAG wires. What is often not explained

is how they deliver these higher values and whether these can be

utilised. For example, if a solid MIG/MAG wire is used at 250 amps,

then exchanged for a ux cored wire of the same diameter, and welding

power source controls are left unchanged, then the current reading

would be much less than 250 amps, perhaps as low as 220 amps. This

is because of Ohms Law that states that as the electrical resistance

increases if the voltage remains stable then the current must fall.

To bring the welding current back to 250 amps it is necessary to

increase the wire feed speed, eectively increasing the amount of

wire being pushed into the weld pool to make the weld. It is this aect

that produces the ‘higher deposition rates’ that the ux cored wire

manufacturers claim for this type of product. Unfortunately in many

instances the welder has diculty in utilising this higher wire feed speed

and must either increase the welding speed or increase the size of the

weld. Often in manual applications neither of these changes can be

implemented and the welder simply reduces the wire feed speed back

to where it was and the advantages are lost. However, if the process

is automated in some way then the process can show improvements

inproductivity.

It is also common to use longer contact tip to workplace distances with

ux cored arc welding than with solid wire MIG/MAG welding and this

also has the eect of increasing the resistive heating on the wire further

accentuating the drop in welding current. Research has also shown

that increasing this distance can lead to an increase in the ingress of

nitrogen and hydrogen into the weld pool, which can aect the quality

of the weld.

Flux cored arc welding has a lower eciency than solid wire MIG/MAG

welding because part of the wire ll contains slag forming agents.

Although the eciency varies diers by wire type and manufacturer it is

typically between 75–85%.

Flux cored arc welding does, however, have the same drawback as solid

wire MIG/MAG in terms of gas disruption by wind, and screening is

always necessary for site work. It also incurs the extra cost of shielding

gas, but this is often outweighed by gains in productivity.

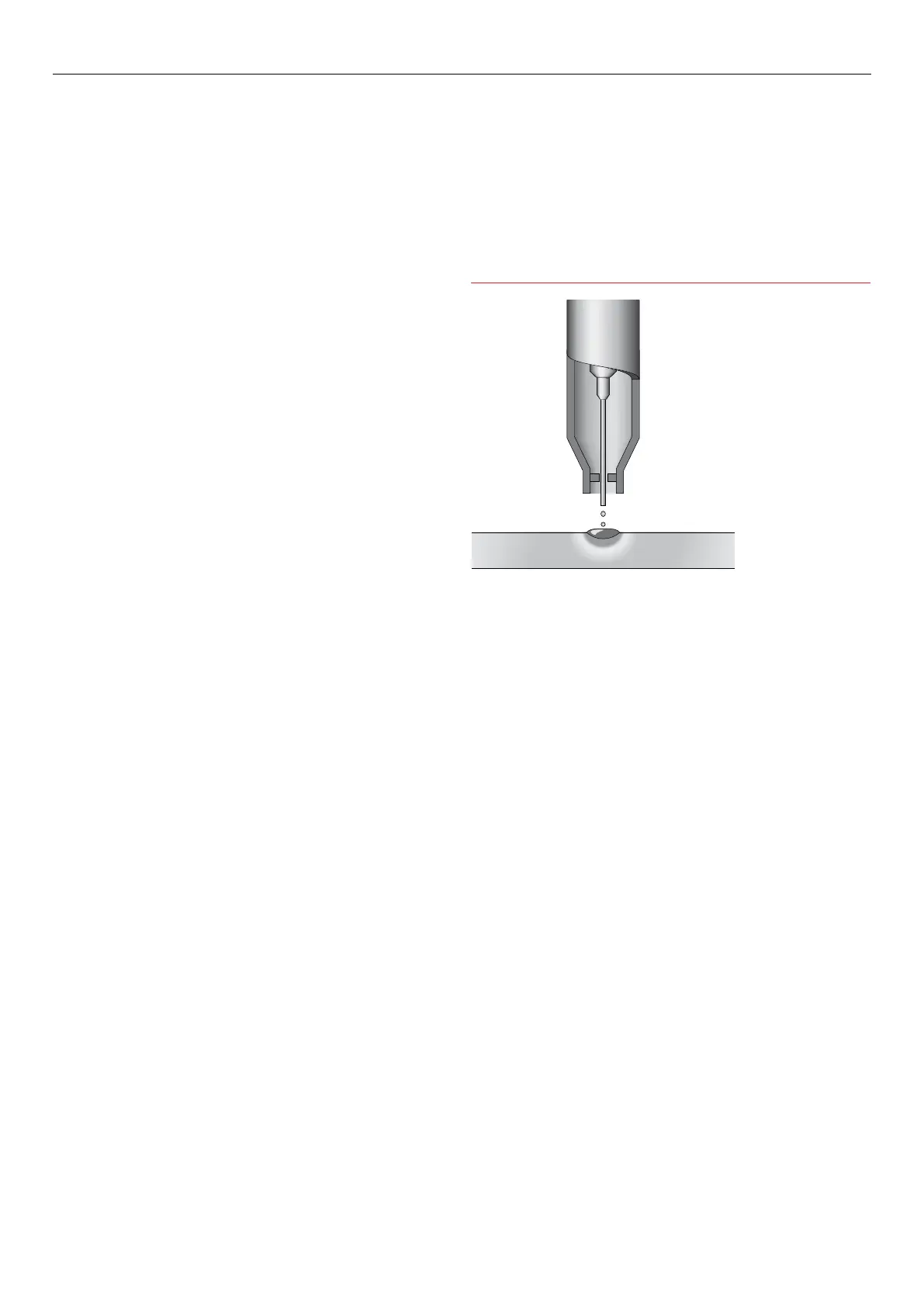

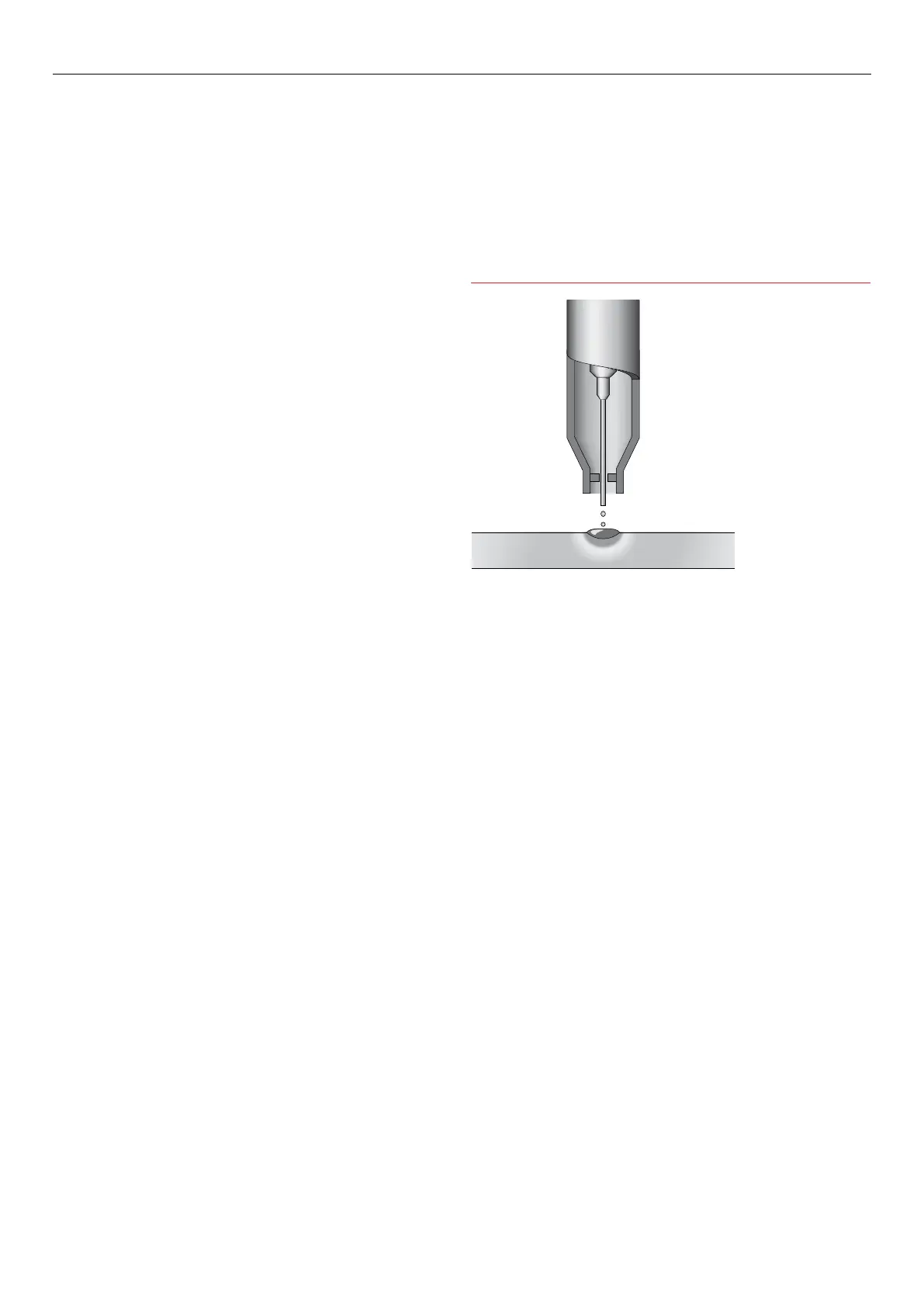

Self-shielded operation

There are also self-shielded consumables designed to operate without

an additional gas shield. In this type of product, arc shielding is provided

by gases generated by decomposition of some constituents within the

ux ll. These types of wire are referred to as ‘self-shielded’.

Extended self shielded ux cored wire nozzle

Loading...

Loading...