Process variable Explanation Usage

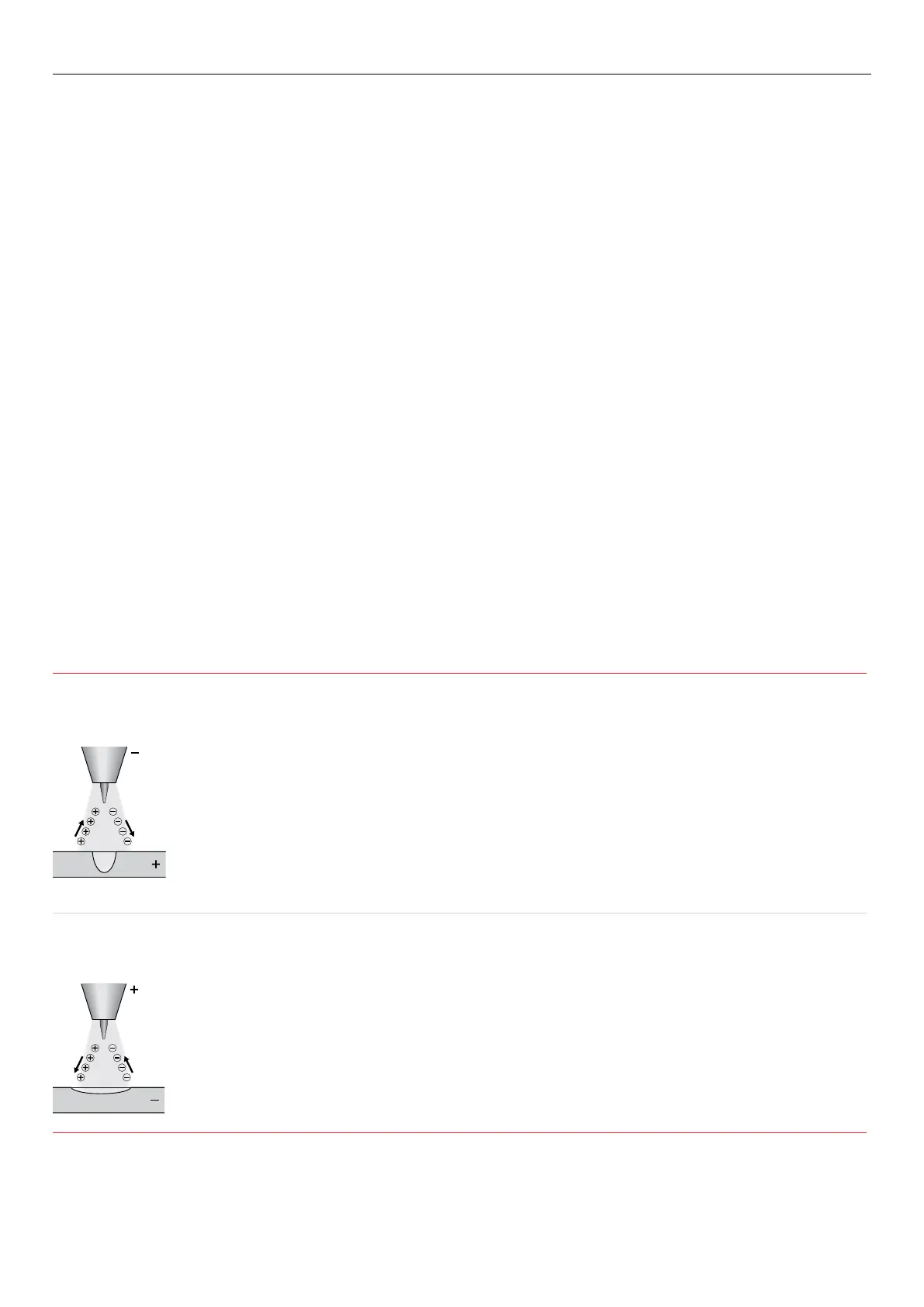

DCEN

Narrow bead,

deeppenetration

Nozzle

Ions Electrons

When direct-current electrode-negative (straight polarity)

is used:

→ Electrons strike the part being welded at a highspeed

→ Intense heat on the base metal is produced

→ The base metal melts very quickly

→ Ions from the inert gas are directed towards the

negative electrode at a relatively slow rate

→ Direct current with straight polarity does not require

post-weld cleaning to remove metaloxides

For a given diameter of tungsten electrode, higher

amperage can be used with straight polarity. Straight

polarity is used mainly for welding:

→ Carbon steels

→ Stainless steels

→ Copper alloys

The increased amperage provides:

→ Deeper penetration

→ Increased welding speed

→ A narrower, deeper, weld bead

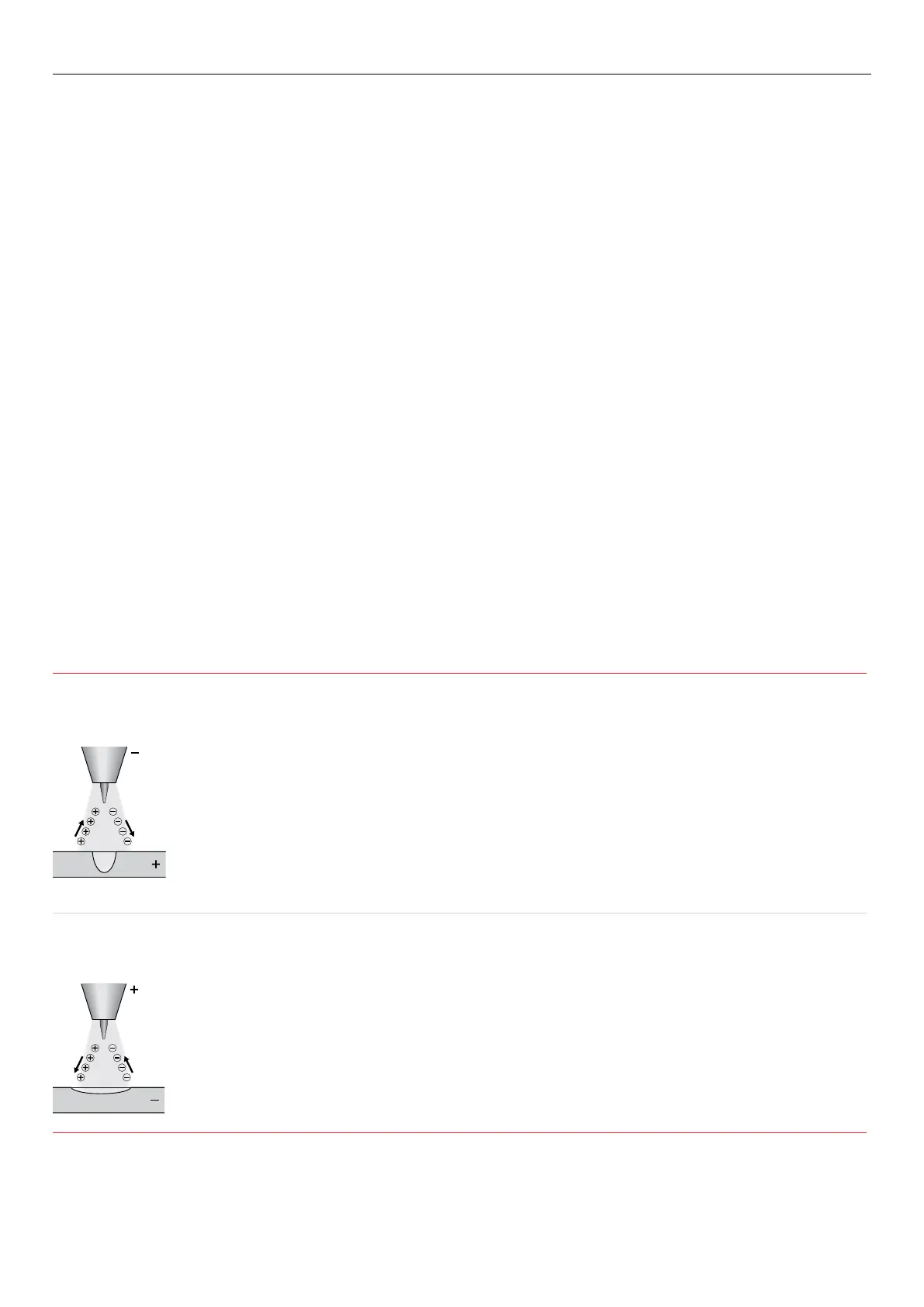

DCEP

Wide bead,

shallowpenetration

Nozzle

Ions Electrons

The DCEP (reverse polarity) are dierent from the DCEN in

followingways:

→ High heat is produced on the electrode rather on the

base metal

→ The heat melts the tungsten electrode tip

→ The base metal remains relatively cool compared to

sing straight polarity

→ Relatively shallow penetration is obtained

→ An electrode whose diameter is too large will reduce

visibility and increase arc instability

→ Intense heat means a larger diameter of electrode

must be used with DCEP

→ Maximum welding amperage should be relatively low

(approximately six times lower than with DCEN)

43BOC Smootharc Multi 180/200 Operating manual

Loading...

Loading...