Installation 8200 Compressor

Final Preparation of Compressor Installation, Operation, and Service Instructions

8040353 Brooks Automation

4-8 Revision AA

Final Preparation of Compressor

1. Using a voltmeter, measure the phase-to-phase voltage from the power source.

Compare this voltage to Table 4-1 and position the voltage range selector

switch to the “208V” or “220V” position as required. Also, set the frequency

selector switch to the 50 Hz or 60 Hz position, as appropriate. See Figure 1-2 on

page 1-4 for location of selector switches.

2. Ensure that water is turned on for the water-cooled compressor.

3. Set the compressor ON/OFF switch (3) to OFF. Connect the input-power cable

to the power source Refer to Table 1-1 on page 1-5, for electrical power require-

ments.

4. Turn the compressor switch to the ON position and allow the compressor to

run for 15 minutes to stabilize the oil circuit. Make sure that the compressor fan

operates freely in the air-cooled compressor.

5. Switch off the compressor and disconnect the input-power cable.

6. Install the compressor in its permanent location on a level surface. Air cooled

units must have a minimum clearance of 12 inches at the front and back for

adequate airflow.

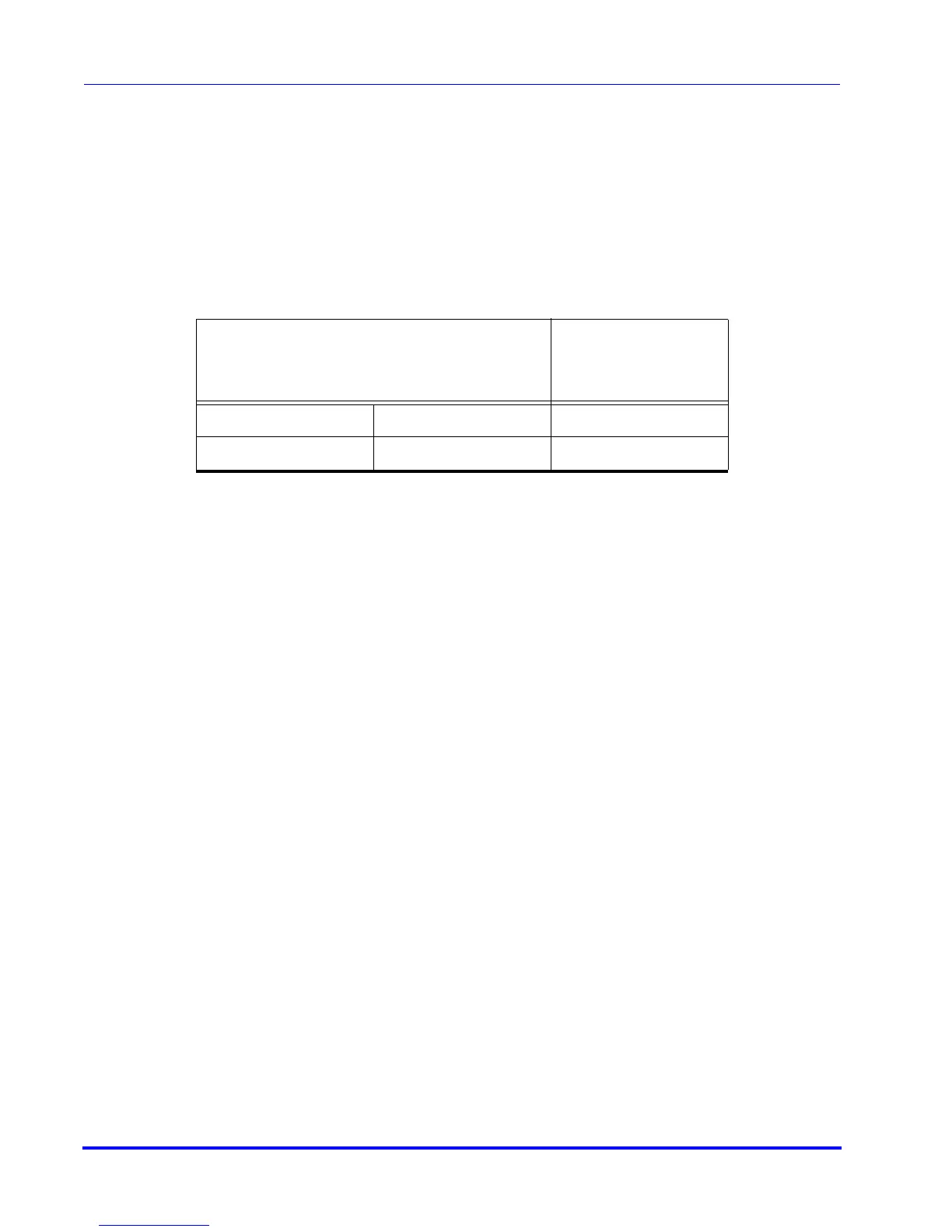

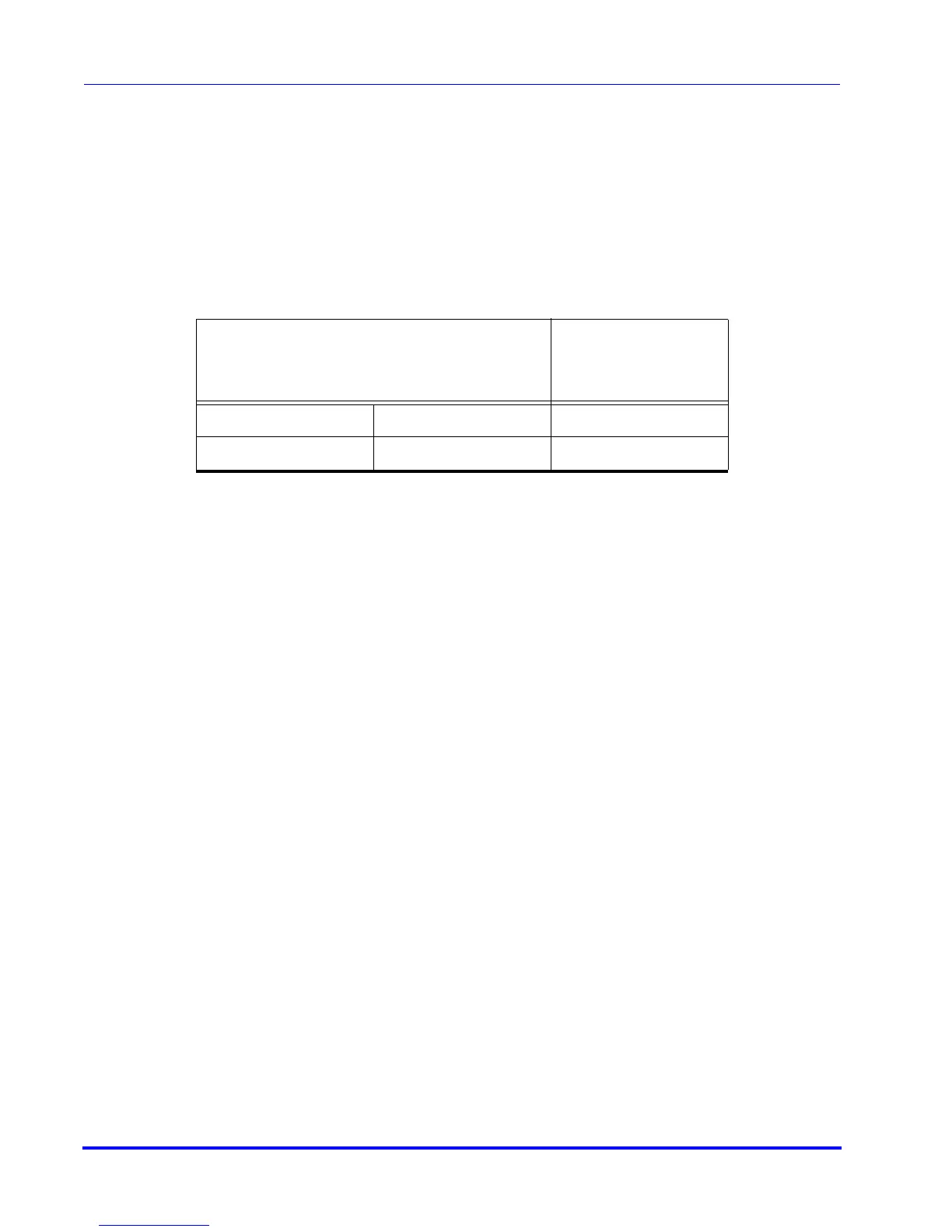

Table 4-1: Voltage Specifications

Operating Voltage Range

60 Hz 50 Hz

Voltage

Adjustment

Switch S1 Position

198-212 180-212 208V

213-250 213-220 220V

Loading...

Loading...