8200 Compressor Appendices

Installation, Operation, and Service Instructions Appendix B: Troubleshooting Proce-

Brooks Automation 8040353

Revision AA

6-7

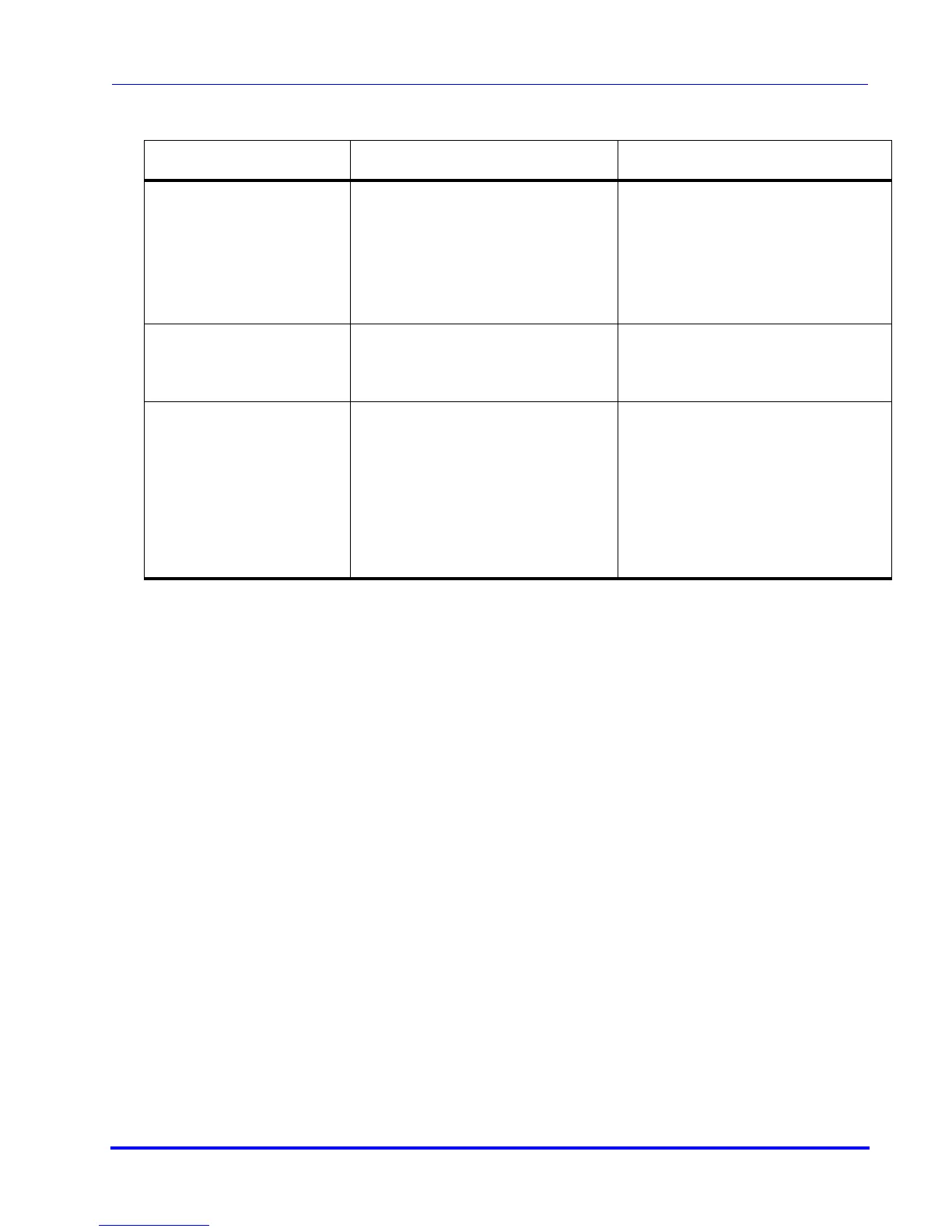

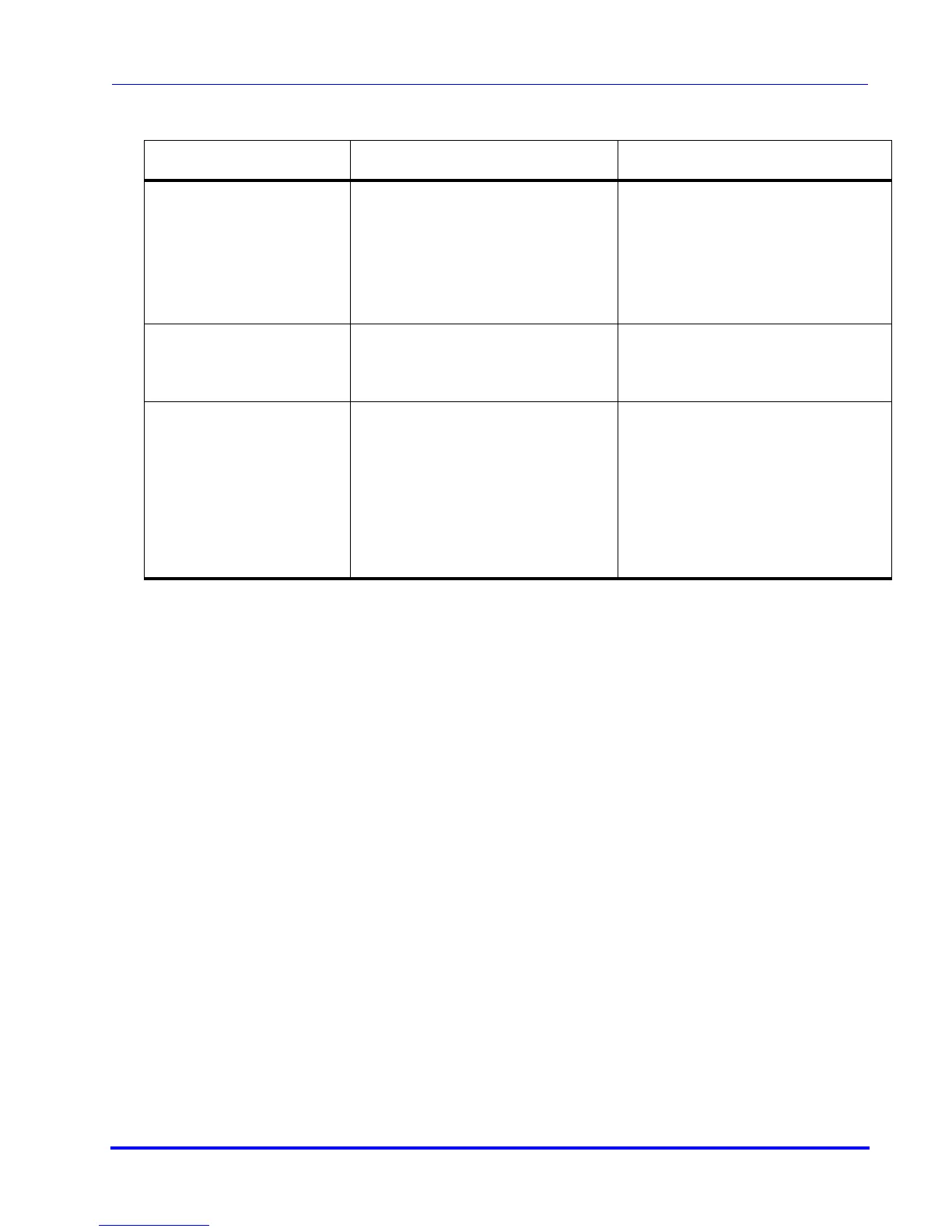

4) Compressor pump

stops after several

minutes of operating

and then switches ON

and OFF at short inter-

vals.

4a) Intermittent power source

voltage.

4a) Confirm power source

voltage between 198-250V, 60

Hz or 180-220V, 50 Hz and

restore if necessary.

5) Compressor oper-

ates but cold head

motor does not run.

5a) Loose or defective cable. 5a) Check cold head cable.

6) Cooling water leav-

ing the compressor

exceeds 100°F.

6a) The water coming into the

compressor is too warm.

6a) Ensure the water coming

into the compressor is between

50°F (32º C) and 90°F (10º C).

6b) The water is becoming too

warm within the compressor

due to a problem with the

compressor.

6b) Contact the Product Ser-

vice Department.

Table 6-1: Compressor Troubleshooting Procedures

Problem Possible Cause Corrective Action

Loading...

Loading...