115

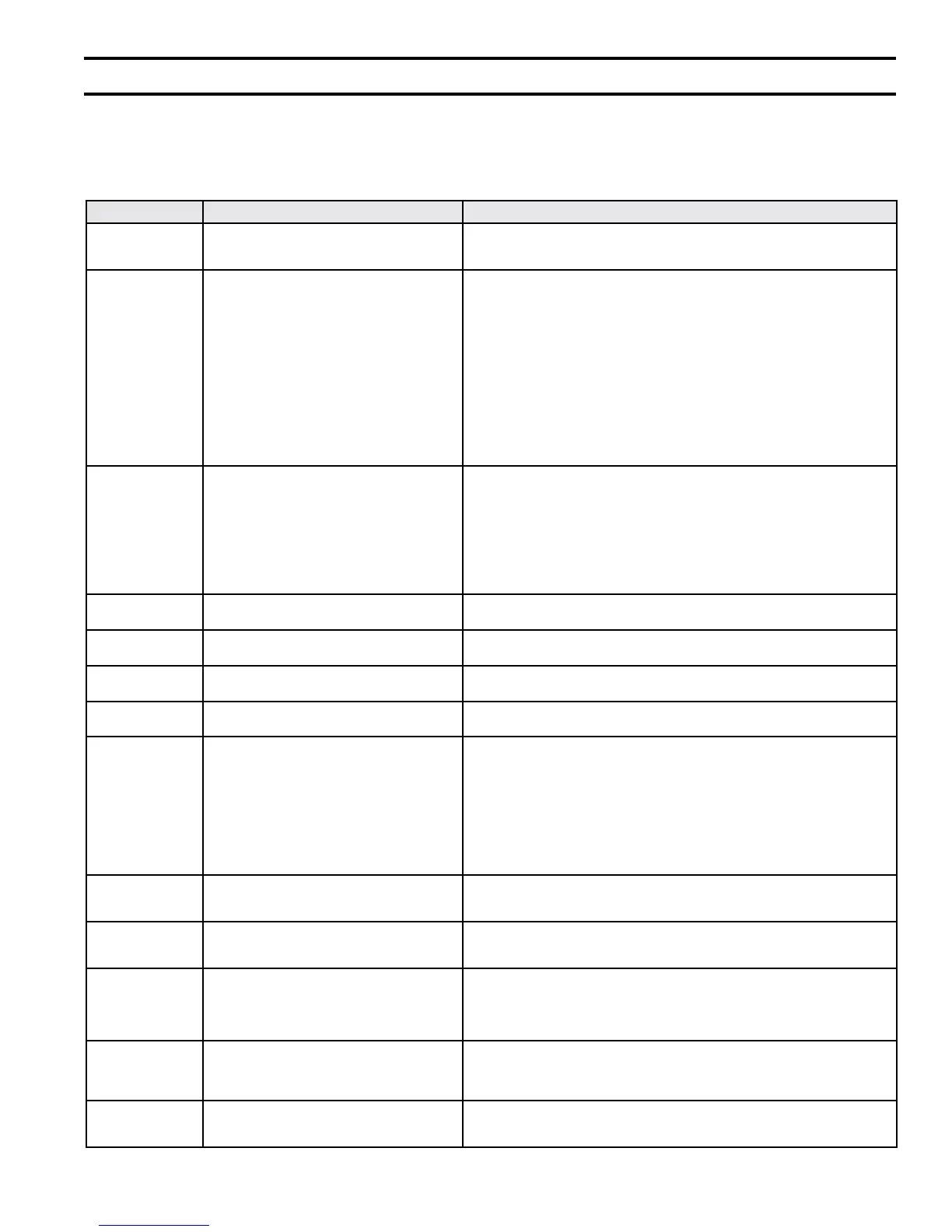

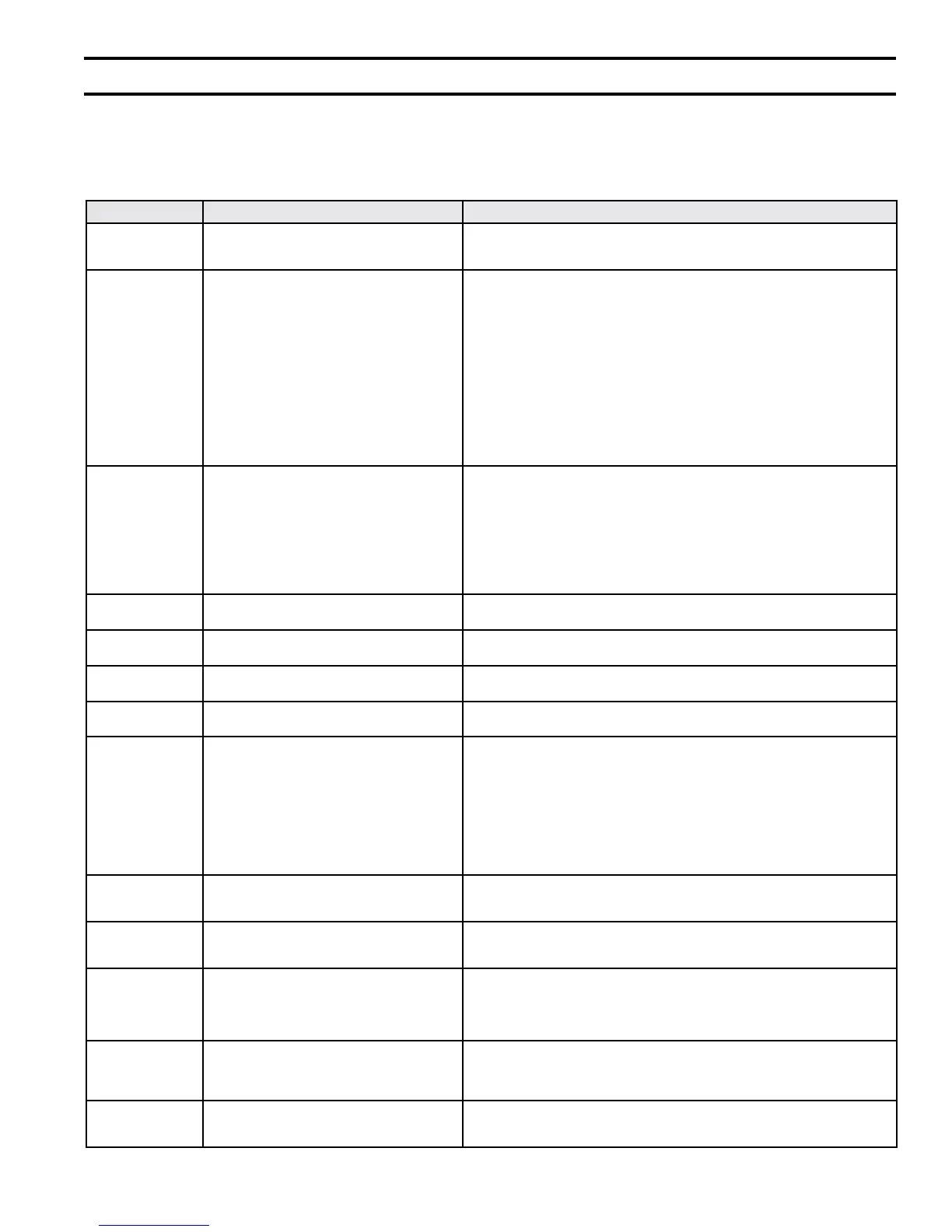

XIV. Troubleshooting (continued)

Soft Lockout Codes Displayed

B. Troubleshooting problems where a Soft Lockout

Code is displayed. When a soft lockout occurs, the

boiler will shut down, the display will turn red and

Lockout Number Condition Possible Cause

1

Anti Short Cycle

Minimum time between starts has not been

reached. Normal delay used to avoid excessive

cycles.

2

Boiler Safety Limit

Open

Boiler Safety Limit wired to terminals J6-1, 2 or 3

OPEN:

• Condensate Trap Float Switch

contacts open.

• Air Pressure Switch contacts open.

• Auto Reset High Limit contact open.

• Loose wiring to limit device.

• Auto Reset Supply high limit sensor detected temperatures in excess of 200°F.

• Defective Auto Reset Supply High Limit Switch.

• Plugged Condensate Trap - also check to ensure boiler is level.

• Air Pressure Switch contacts open - check for blocked vent.

• See possible causes for “Hard Lockout 4

”.

NOTE

Block Vent Special Note

Before a call for heat the air pressure switch is closed. When there is a call for heat

with a blocked vent the air pressure switch will open (due to excessive pressure of

the fan against a blocked ue pipe) after the fan starts. The control stops the start

sequence and stops the fan. After the fan stops the pressure switch re-closes and the

cycle continues. The displays shows the cause of trip for only the time the pressure

switch is open.

3

Boiler Safety Limit

Open,

(ILK Off)

Boiler Safety Limit, or External Limit wired to termi-

nals J5-1 OPEN:

• Jumper for External Limit wired to

terminals 11 and 12 or device connected

to it open.

• Jumper for Low Water Cutoff (LWCO)

Switch or device connected to it open.

• Jumper for Low Gas Pressure Switch or

device connected to it open.

•

See possible causes for “Hard Lockout

4”.

• Loose wiring to limit device.

•

External Limit defective or jumper not installed.

• Low Gas Pressure Switch contacts open (if installed).

• LWCO switch not installed and jumper missing.

• If yellow light on LWCO is on, system is low on water.

• If neither yellow or green light is on, check LWCO harness.

7

Return sensor fault

Shorted or open return temperature sensor.

• Shorted or mis-wired return sensor wiring.

•

Defective return sensor.

8

Supply sensor fault

Shorted or open supply temperature sensor.

• Shorted or mis-wired supply sensor wiring.

•

Defective supply sensor.

9

DHW sensor fault

Shorted or open Domestic Hot Water (DHW)

temperature sensor.

• Shorted or mis-wired DHW sensor wiring.

•

Defective DHW sensor.

10

Stack sensor fault

Shorted or open ue gas (stack) temperature

sensor.

• Shorted or mis-wired stack sensor wiring.

•

Defective stack sensor.

11

Ignition failure

Flame failure after 5 tries to restart.

• No gas pressure.

•

Gas pressure under minimum value shown on rating plate.

• Gas line not completely purged of air.

• Defective Electrode.

• Loose burner ground connection.

• Defective Ignition Cable.

• Defective gas valve (check for 24 Vac at harness during trial for ignition before

replacing valve).

• Air-fuel mixture out of adjustment - consult factory

.

13

Flame rod

shorted to ground

Flame rod shorted to ground

• Shorted or mis-wired ame rode wiring.

•

Defective ame rod.

14

Delta T inlet/outlet

high

Temperature rise between supply and return is too

high.

• Inadequate boiler water ow

. Verify that pump is operating and that pump and

piping are sized per Section VI of this manual.

15

Return temp higher

than supply

Sage2.1 is reading a return sensor temperature

higher than the supply sensor temperature.

Condition must be present for at least 75 seconds

for this error code to appear.

• Flow through boiler reversed. V

erify correct piping and pump orientation.

• No boiler water ow. Verify that system is purged of air and that appropriate valves

are open.

• Sensor wiring reversed.

• Supply or return sensor defective.

16

Supply temp has

risen too quickly

Supply water temperature has risen too quickly.

• See possible causes for “Hard Lockout

4”.

• Inadequate boiler water ow.

• Verify that pump is operating and that pump and piping are sized per Section VI of

this manual.

17

Fan speed not

proved

Normal waiting for fan speed to match purge and

light-off setpoint.

the “Help” button will “blink”. Select the “blinking”

“Help” button to determine the cause of the soft

lockout. The boiler will automatically restart once the

condition that caused the lockout is corrected.

Loading...

Loading...