66

e. Individual module (boiler) sidewall concentric

vent terminals must be placed at least twelve

(12) inches above the ground plus the expected

snow accumulation.

f. For vertical through the roof venting any

adjacent individual module (boiler) vertical

vent terminals, if level with each other, must be

spaced no closer than 12 inches horizontally.

If vertical vent terminals cannot end in one

plane, they must be spaced no closer than three

(3) feet horizontally.

g. Chimney chase concentric venting is permitted

for modules, when stackable, providing

concentric vertical (roof) vent terminals, if level

with each other, are spaced no closer then 12

inches horizontally.

If vertical vent terminals cannot end in one

plane, they must be spaced no closer then three

(3) feet horizontally.

h. When individual modules (boilers) are installed

in the same horizontal plane, chimney chase

vertical concentric venting is permitted provided:

i. Sufcient inside space available at the base

of the chimney to install multiple chimney

chase brackets and support elbows.

ii. Spacing between adjacent vertical vent

terminals is in accordance with paragraph g

above.

CAUTION

Installing multiple individual module (boiler)

concentric vent terminations too close together

may result in combustion product water vapor

condensation on building surfaces, where

termination are placed, and subsequent frost

damage. To avoid/minimize frost damage extend

the distance from building surfaces to concentric

vent termination end as well as increase the

horizontal distance between adjacent concentric

vent terminations.

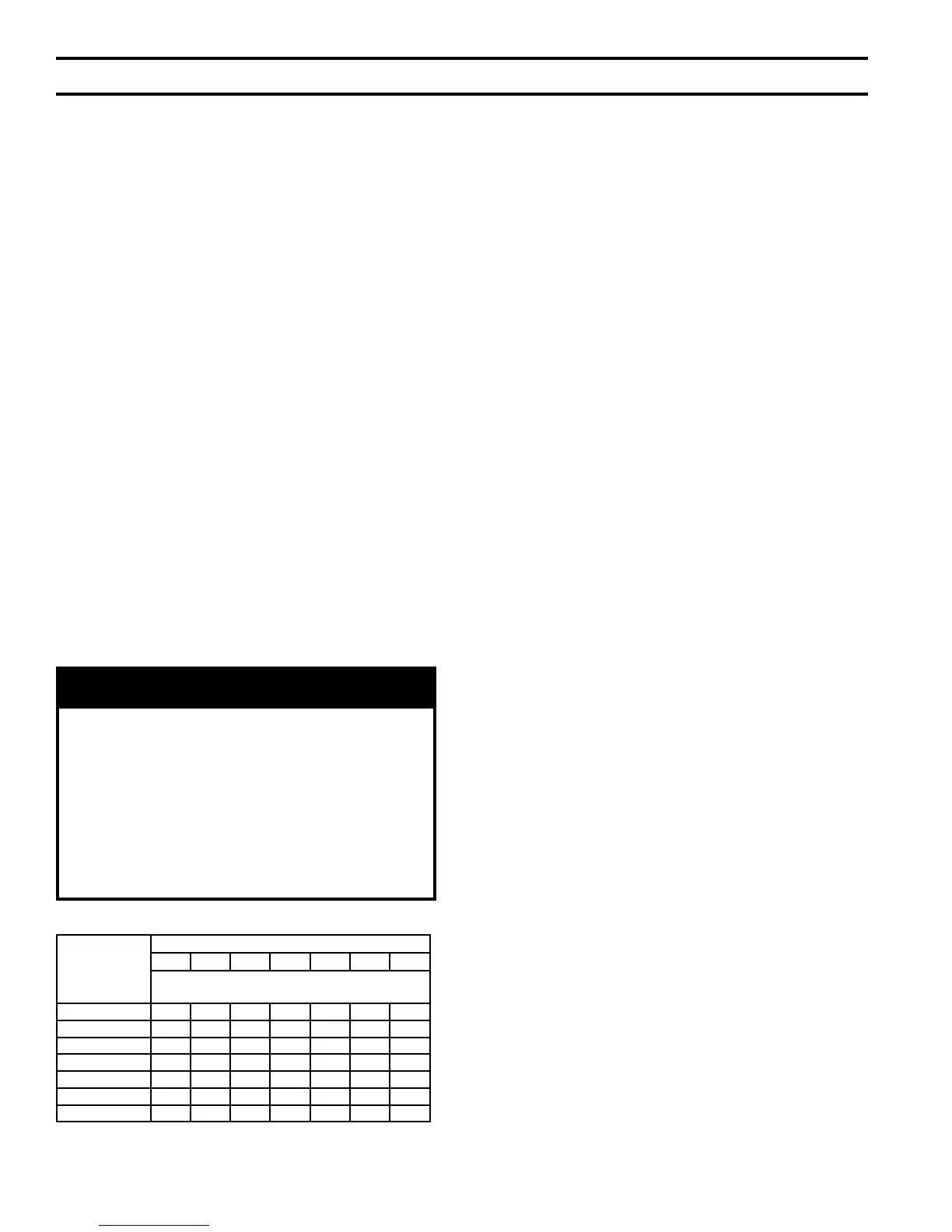

C. Water Piping – (See Table 20 and Figure 41)

1. Refer to Section VI “Water Piping and Trim” of this

manual for:

a. Installation of Factory Supplied Piping and

Trim

Components for an individual module (boiler).

b. Regarding an individual module (boiler) piping

system specic details.

c. Selection criteria for individual module (boiler)

space heating and/or DHW circulators.

2. For installations where indirect domestic hot water

heater is combined with space heating, when sizing

an indirect water heater circulator

, compare the

specied ow range through an Alpine model boiler

to an indirect water heater (Alliance SL™) model

coil ow rate required to achieve water heater

rating. Refer to Table 21.

a. When Alliance SL™ model coil ow rate,

required to achieve water heater rating, falls

within the specied ow range for Alpine

boiler model, the Alliance SL™ model can be

piped as part of Alpine near-boiler piping.

Refer to Table 21.

b. When Alliance SL™ model coil ow rate,

required to achieve water heater rating,

exceeds the specied ow range for Alpine

boiler model, the Alliance SL™/Alpine boiler

combination may result in excessive noise and

boiler heat exchanger erosion, and therefore,

is not recommended. Refer to Table 21 for

details.

c. When Alliance SL™ model coil ow rate,

required to achieve water heater rating, falls

below the specied ow range for Alpine boiler

model, the Alliance SL™ model must be piped

as a separate heating zone off the system

header. The circulator must be sized based on

the Alliance SL™ model coil ow and combined

coil pressure drop and the zone piping total

equivalent length. Refer to Table 21 for details.

D. Gas Piping

1. Individual module (boiler) gas pipe sizing specic

details

2. Individual module (boiler) recommended gas piping.

See Figure 34A.

3. Requirement to install additional gas pressure

regulators to properly regulate gas pressure at the

input of the smallest individual module (boiler).

T

able 20: Modular Boiler Water Manifold Sizing

Boiler Model

Number of Units

2 3 4 5 6 7 8

Recommended Minimum Common Water

Manifold Size (N

PT)

ALP080 1¼” 1½” 1½” 2” 2” 2” 2½”

ALP105 1¼” 1½” 2” 2” 2½” 2½” 2½”

ALP150 1½”

2” 2½” 3” 3

” 3” 3”

ALP210 2” 2½” 2½” 3” 3

½” 3½” 3½”

ALP285 2” 3” 3

” 3½” 4” 4” 5”

ALP399 2½” 3” 3

” 4” 5” 5” 5”

ALP500 3” 4” 4” 5” 5” 6” 6”

X. Modular Installation (continued)

Loading...

Loading...