22

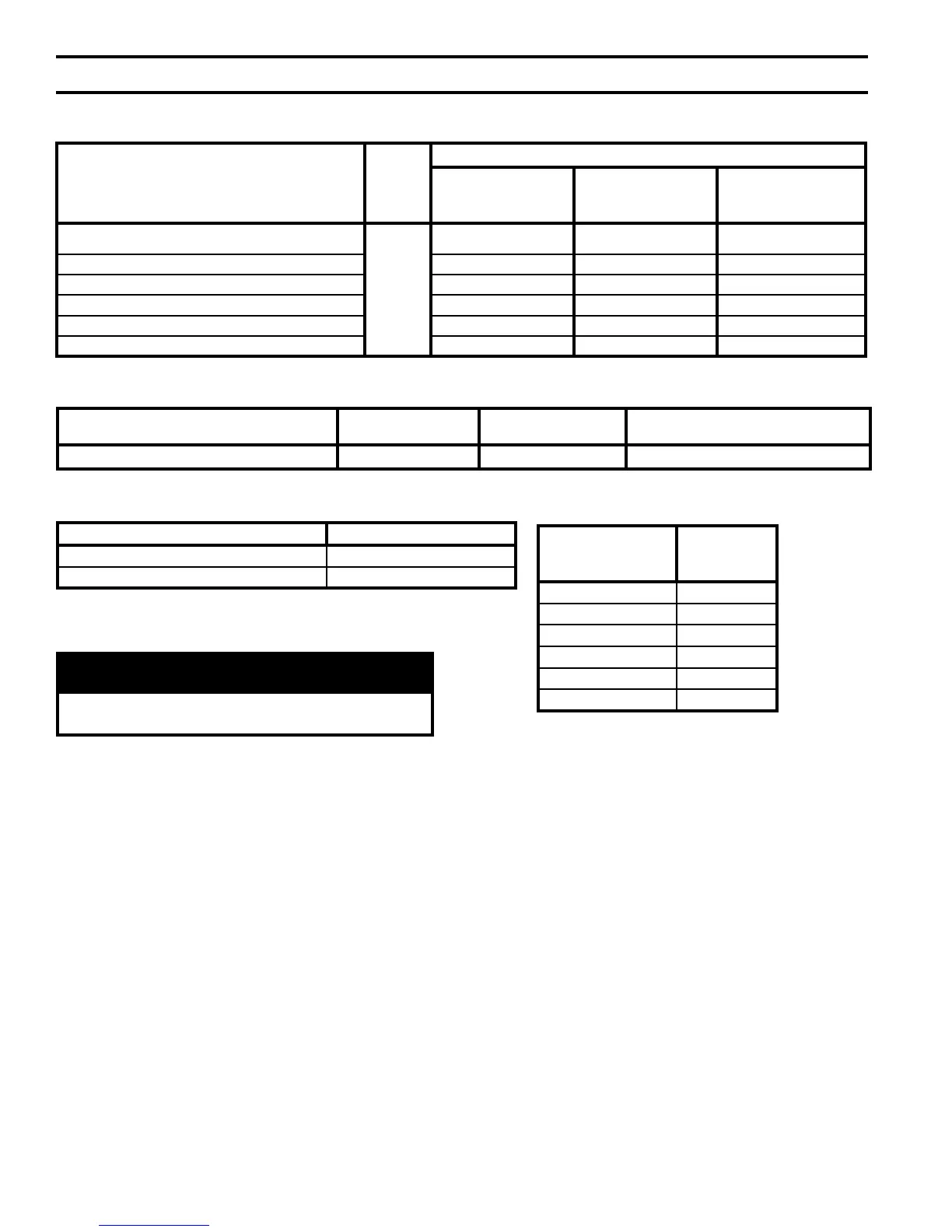

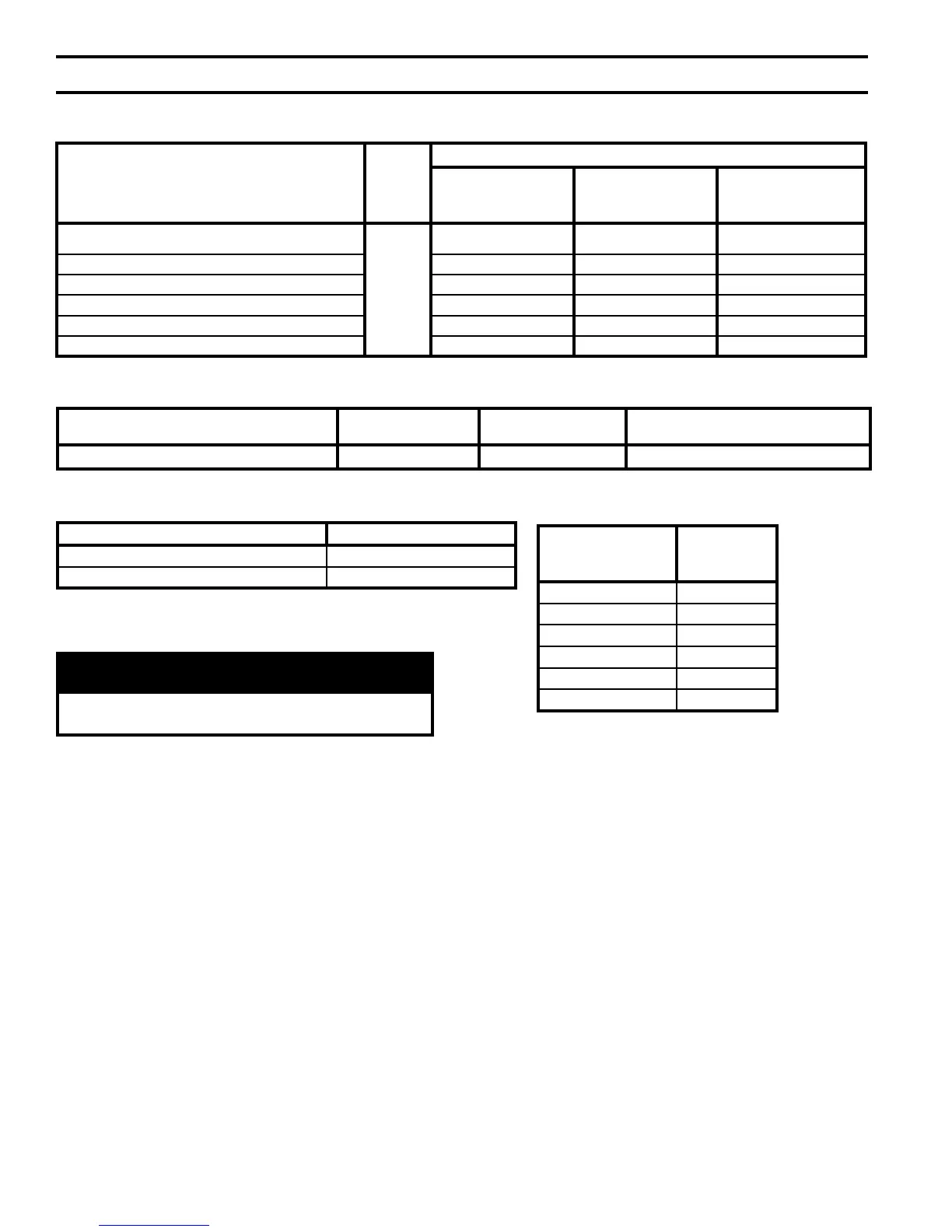

Table 6: Vent System and Combustion Air System Components

Vent System Component Equivalent Length (Ft.)

Schedule 40 CPVC Pipe x 30 Inches 2.5

Schedule 80 CPVC 90° Elbow 5

Combustion Air

System Component

(Parts by Others)

Equivalent

Feet of Pipe*

Pipe x 1 Ft. 1

Pipe x 2 Ft. 2

Pipe x 4 Ft. 4

Pipe x 5 Ft. 5

Elbow 5

Elbow 2.5

*Equivalent Feet of Pipe Based on

Standard 4” PVC Design

Table 5: Clearances from Vent Piping to Combustible Material

Vent Pipe Pipe Direction Enclosure

Minimum Clearance To

Combustible Material

CPVC/PVC Venting Vertical or Horizontal Enclosed at all Sides See Figures 2A and 2B

Vent Components

Part

Number

Quantity

ALP080 & A

LP105

Horizontal (Snorkel)

Termination

ALP150& A

LP210

Horizontal (Snorkel)

Termination

ALP285 thru ALP500

Horizontal (Snorkel)

Termination

3" Schedule 40 PVC Pipe x up to 7 ft. max. vertical run

N/A

Supplied by

Others

2 1 N/A

4" Schedule 40 PVC Pipe x up to 7 ft. max. vertical run N/A 1 2

3" Schedule 40 PVC 90° Elbow

4 2 N/A

4" Schedule 40 PVC 90° Elbow

N/A 2 4

3" Schedule 40 PVC Pipe x ½ ft. min. horizontal run

2 1 N/A

4" Schedule 40 PVC Pipe x ½ ft. min. horizontal run

N/A 1 2

Table 4C: CPVC/PVC Vent & Air Intake Components (Installer Provided) required for Optional Horizontal

(Snorkel) Termination

WARNING

All condensate that forms in the vent must be

able to drain back to the boiler.

b. V

ent length restrictions are based on equivalent

length of vent/combustion air pipe (total length

of straight pipe plus equivalent length of

ttings). Maximum vent/combustion air lengths

are listed in Table 7. Do not exceed maximum

vent/combustion air lengths. Table 6 lists

equivalent lengths for ttings. Do not include

vent/combustion air terminals in equivalent

feet calculations. See “Combustion Air/Vent,

Equivalent Length Work Sheet”.

c. The vent termination location is restricted as per

'General Guidelines', Paragraph A, 5.

(Refer to Figure 3).

2. System Assembly

a. Plan venting system to avoid possible contact

with plumbing or electrical wires. Start at

vent connector at boiler and work towards vent

termination.

b. Do not exceed maximum Vent/Combustion Air

length. Refer to Table 7.

c. Design the Vent System to allow 3/8" of thermal

expansion per 10 feet of CPVC/PVC pipe. Runs

of 20 feet or longer that restrained at both ends

must use an offset or expansion loop. Refer to

Figure 4.

d. Follow all manufacturer instructions and

warnings when preparing pipe ends for joining

and using the primer and the cement.

3. Field Installation of CPVC/PVC Two-Pipe

Vent System Connector - Floor Mounted

Boiler Builds

Refer to Figure 5 and Steps below:

a. Position the CPVC/PVC vent connector and

gasket onto boiler rear/bottom panel and insert

vent connector inner stainless steel vent pipe into

heat exchanger vent outlet.

b. Align vent connector plate and gasket clearance

holes with rear/bottom panel engagement holes;

than, secure the connector and gasket to the

panel with six mounting screws.

IV. Venting (continued)

Loading...

Loading...