30

Vent System

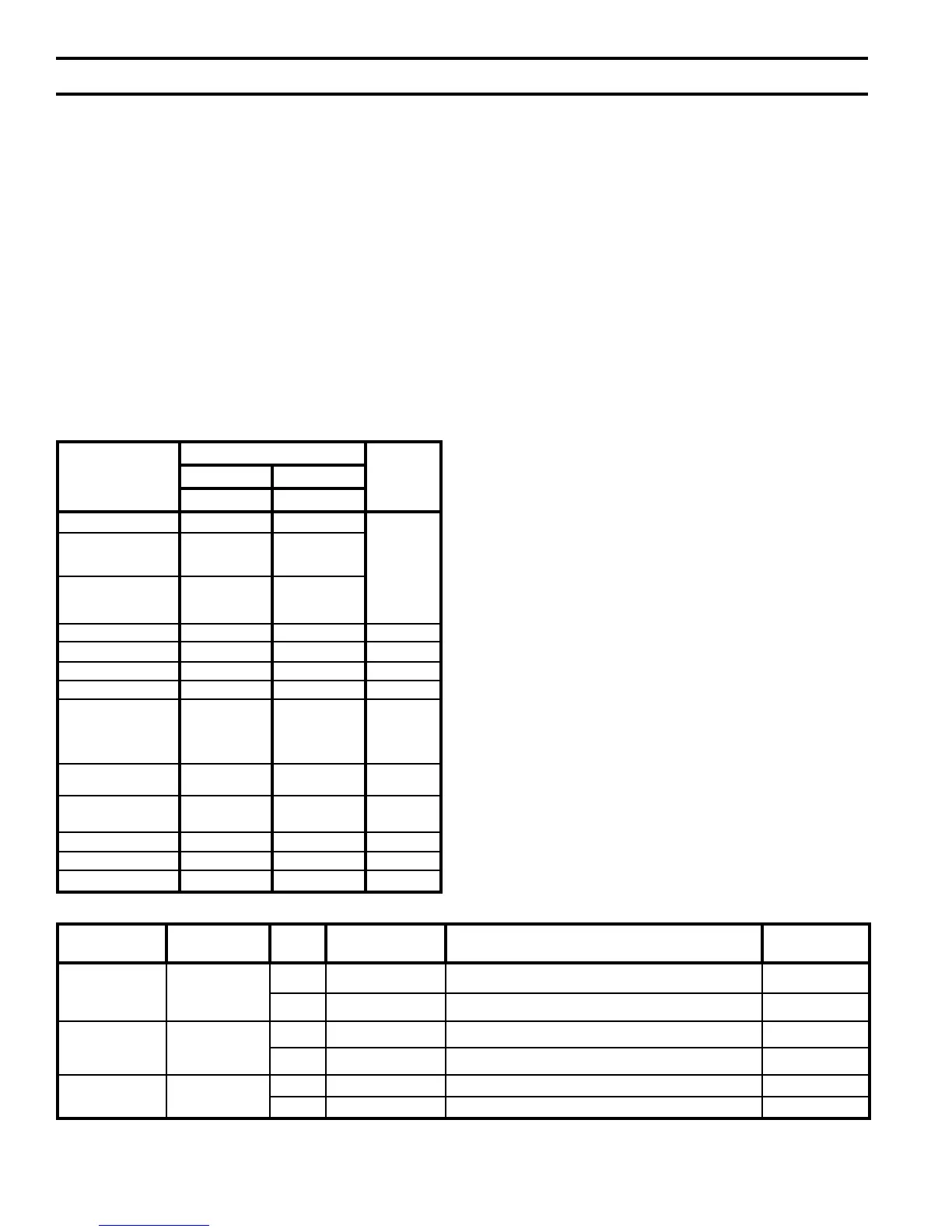

Component

Part Numbers

Equivalent

Feet of Pipe

ALP080 - 210 ALP285 - 500

3" Vent 4" Vent

SS Vent Kit 102501-01 102501-02

N/A

Horizontal Vent

Terminal

(Included in Kit)

8116310 8116313

PVC to SS Vent

Adapter

(Included In Kit)

102219-01 102220-01

Vertical Vent Terminal 102680-01 102680-02 N/A

Pipe x 1 Ft. 8116296U 100176-01 1

Pipe x 3 Ft. 8116298U 100177-01 3

Pipe x 5 Ft. 8116300U 100178-01 5

Pipe x Adjustable 8116319U 100179-01

Equal to

Installed

Length

(1.06 to 1.64)

90° Elbow 8116294U 100180-01

5.5 (3")

8.0 (4")

45° Elbow 8116292U 100181-01

4.0 (3")

4.5 (4")

Horizontal Drain Tee 8116302U 100182-01 2

Vertical Drain Tee 8116304U 100183-01 7½

Single Wall Thimble 8116116 100184-01 N/A

Table 8A: U.S. Boiler Vent System Components

(Stainless Steel)

IV. Venting (continued)

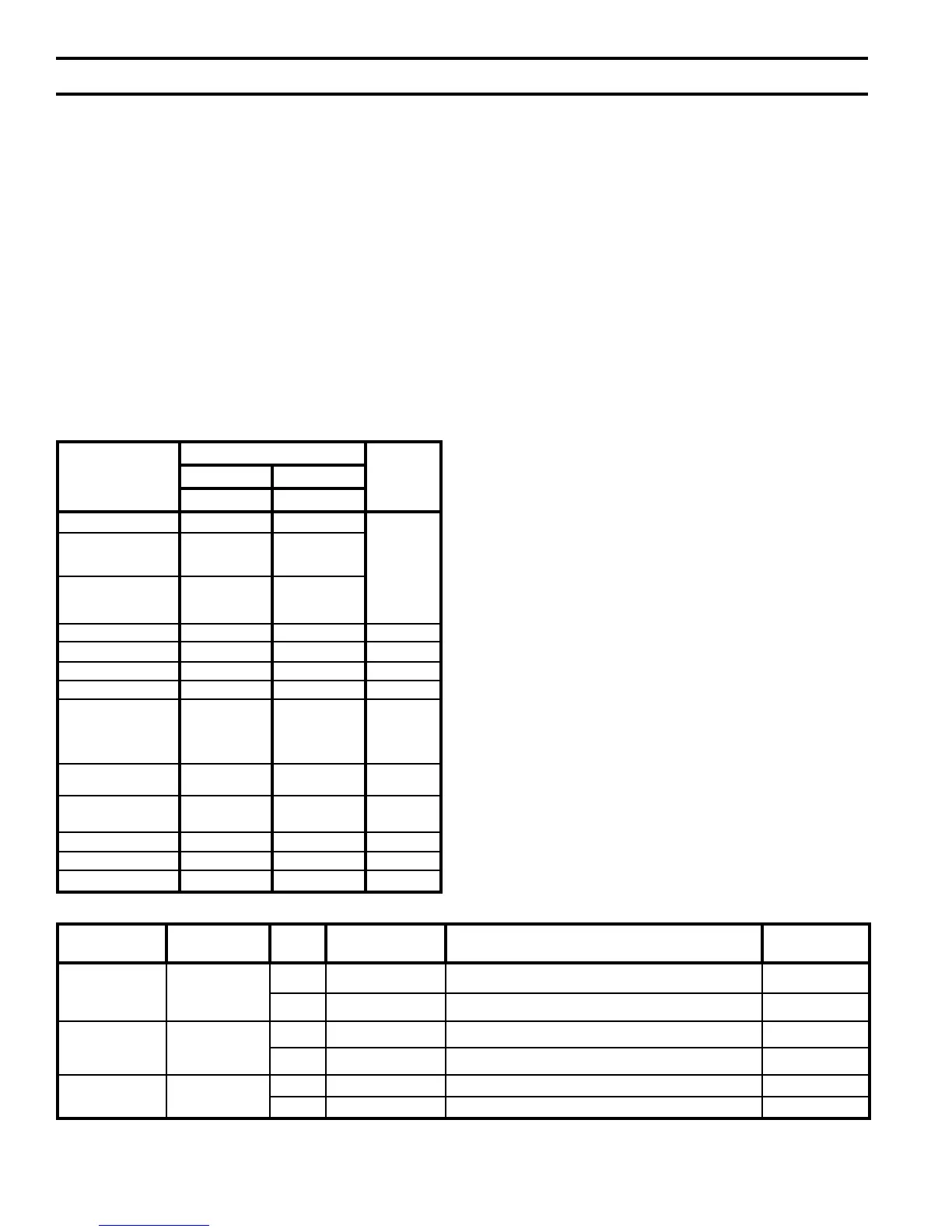

Manufacturer

Vent

System

Size Wall Thimbles Horizontal Termination

Vertical

Termination

Protech

Systems

Inc..

FasNseal

3 FSWT3 Tee: FSTT3 FSBS3

4 FSWT4 Tee: FSTT4 FSBS4

Z-Flex

SVE

Series III

(“Z-Vent III”)

3 2SVSWTEF03 Tee: 2SVSTTF03 24SVSTPF03

4 2SVSWTEF04 Tee: 2SVSTTF04 24SVSTPF04

Flex-L Intl. Star-34

3 SR03WT15 Tee: SRTT-03 SRTP-03

4 SR04WT15 Tee: SRTT-04 SRTP-04

NOTE: See vent system manufacturer’s literature for other part numbers that are required such as straight pipe, elbows, restops

and vent supports.

Table 8B: Alternate Vent Systems and Vent Components (Stainless Steel)

• Male end of terminal will t into the

female end of any of the approved

stainless vent systems.

• Apply a heavy bead of silicone to the

male

end of the terminal before inserting

it into the last piece of pipe. Orient the

terminal so that the seam in the terminal

is at 12:00.

• Smooth the silicone over the seam

between the terminal and the last piece

of pipe, applying additional silicone if

necessary to ensure a tight seal.

• Allow the silicone to cure per the

silicone manufacturer’s instructions

before operating the boiler.

ii. Combustion Air

Termination

• Horizontal intake terminal is a tee in the

upright position. Tee should protrude

the same distance from the wall as the

exhaust terminal. See Figure 8.

• Install a rodent screen (not supplied) in

the inlet terminal. Use a screen having

1/2”

(2 x 2) or larger mesh.

b. Optional Two-Pipe Snorkel Termination

Refer to Figure 10.

This installation will allow a maximum of

seven (7) feet vertical exterior run of the vent/

combustion air piping to be installed on the

approved AL29C Stainless Steel horizontal

venting application.

i. Vent Termination

• After penetrating wall, install the

appropriate manufacturer's 90° elbow so

that the elbow leg is in the up direction.

• Install maximum vertical run of seven

(7) feet of appropriate manufacturer's

vent pipe. See Figure 10.

• At top of vent pipe length install another

appropriate manufacturer's 90° elbow

so that the elbow leg is opposite the

building's exterior surface.

• Install horizontal vent terminal.

• Brace exterior piping if required.

ii. Combustion Air

Termination

• After penetrating wall, install a 90°

elbow so that the elbow leg is in the up

direction.

• Install maximum vertical run of seven

(7) feet of combustion air pipe. See

Figure 10.

• At top of vent pipe length install another

90° elbow os that the elbow leg is

opposite the building's exterior surface.

Loading...

Loading...