19

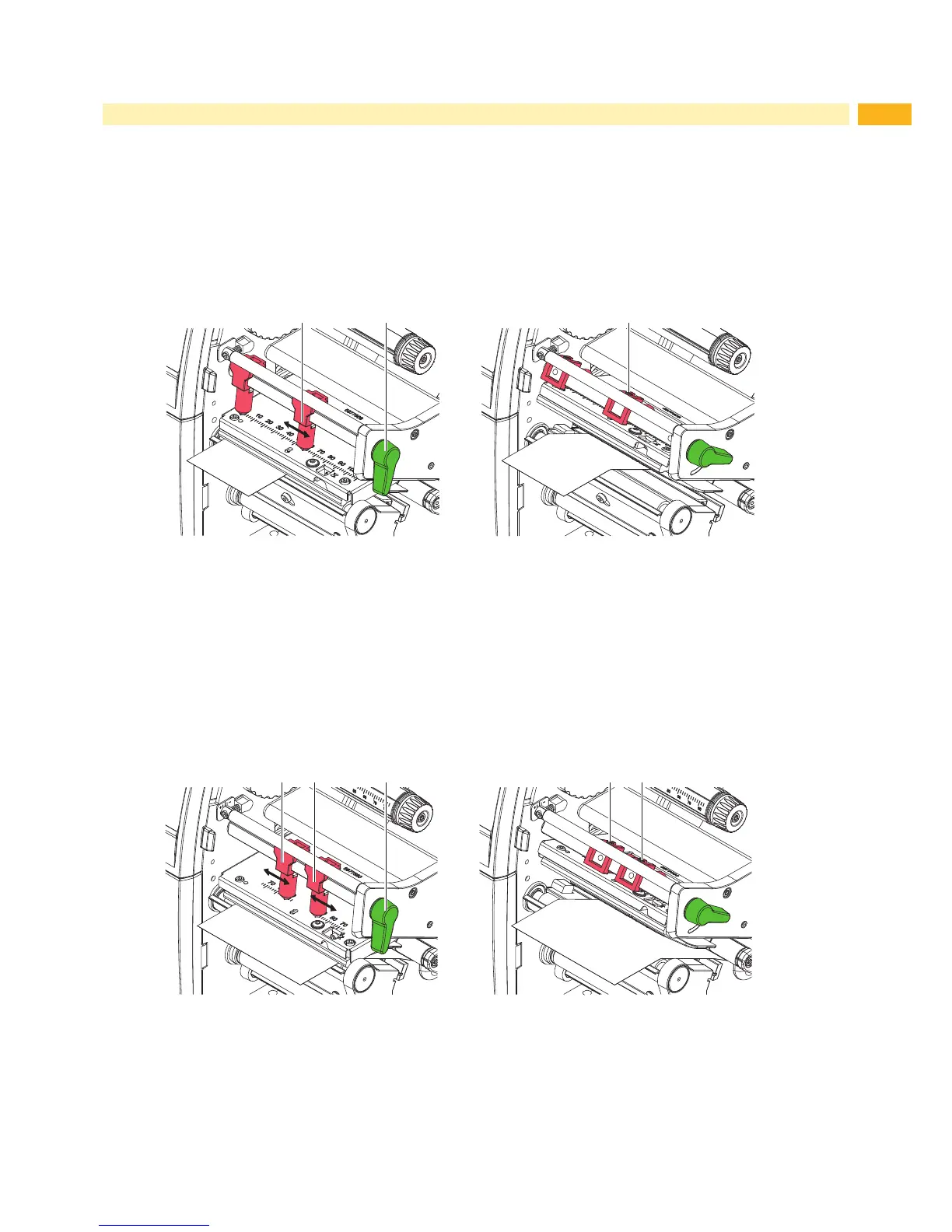

4.3 Setting the Head Locking System

SQUIX 4/4P

The printhead is pushed on via two plungers. The location of the outer plunger must be set to the width of the label

medium used so as to

• achieve even print quality across the entire label width

• prevent wrinkles in the feed path of the transfer ribbon

• prevent premature wearing of the print roller and printhead.

Figure 17 Setting the head locking system SQUIX 4/4P

Loosen threaded pin (3) at outer plunger (1) with Allen key.

Turn lever (2) clockwise to lock the printhead.

Position outer plunger (1) over the outer media edge.

Tighten threaded pin (3).

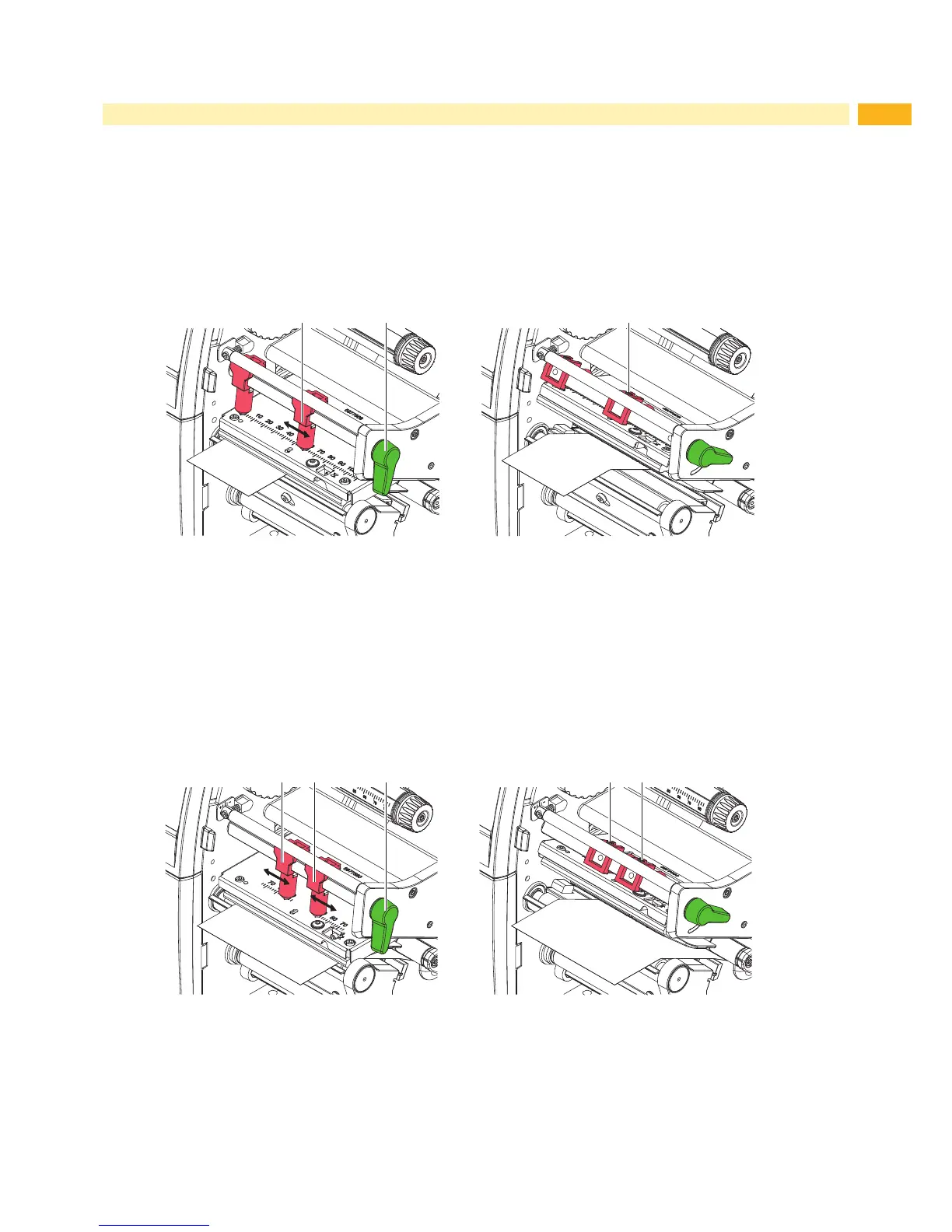

SQUIX 4M/4MP/4MT

The printhead is pushed on via two plungers (1). In the basic setting the plungers are set in the middle of the

printhead retainer. This setting can be used for the most applications.

Figure 18 Setting the head locking system SQUIX 4M/4MP/4MT

If the print density decreases in the outer areas when using very large media, the plungers can be displaced :

Loosen threaded pins (3) at the plungers (1) with Allen key.

Turn lever (2) clockwise to lock the printhead.

Displace plungers to the scale value 70.

Tighten the threaded pins (3).

4 Loading Material

Loading...

Loading...