30

ENG

“SmartCella manual” +0300084EN - rel. 1.2 - 28.03.2017

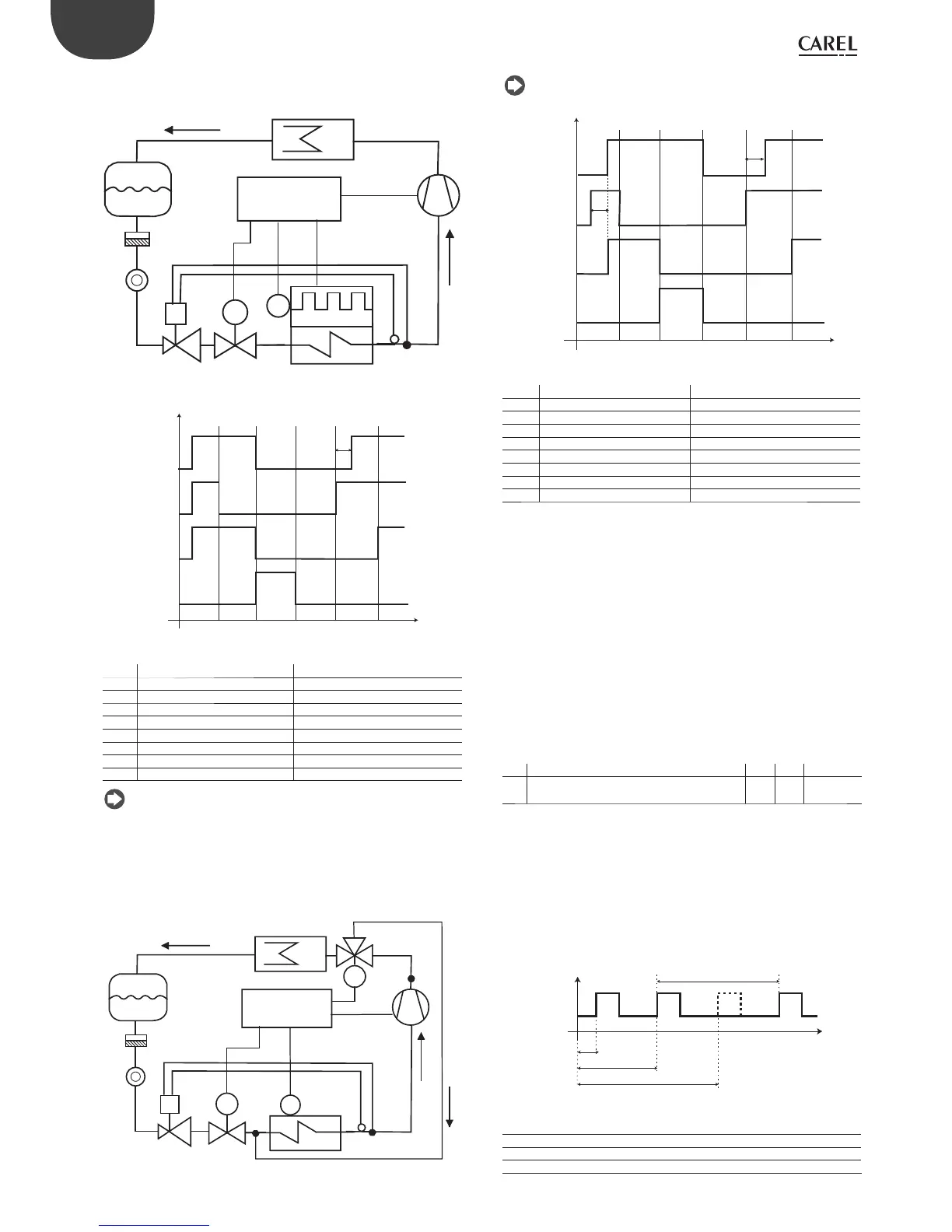

1. Heater defrost (d0 = 0, 2, 4): duty cycle

The duty cycle refers to the default values of parameters F2 and F3.

C

L

CMP

T

V2

E

S2

M

V_Pd

SmartCella

S

F

Fig. 6.l

ON

OFF

ON

OFF

t

CMP

V_Pd

ON

OFF

FAN

ON

OFF

RES

REFRIG PUMP

DOWN

DEF DRIP

(dd)

POST DRIP

(Fd)

REFRIG

c8

Fig. 6.m

Key

CMP Compressor Refrig Cooling

V_Pd Pump down valve Pump down Pump down stage

FAN Evaporator fan Def Defrost

RES Heater Drip Dripping

E Evaporator Post drip Post-dripping

C Condenser S2 Defrost probe

V2 Thermostatic expansion valve L Liquid receiver

F Filter-drier S Liquid gauge

t Time

Note:

• in pump down mode, the behaviour of the fan is determined by F2;

• in defrost, the behaviour of the fan is determined by F3.

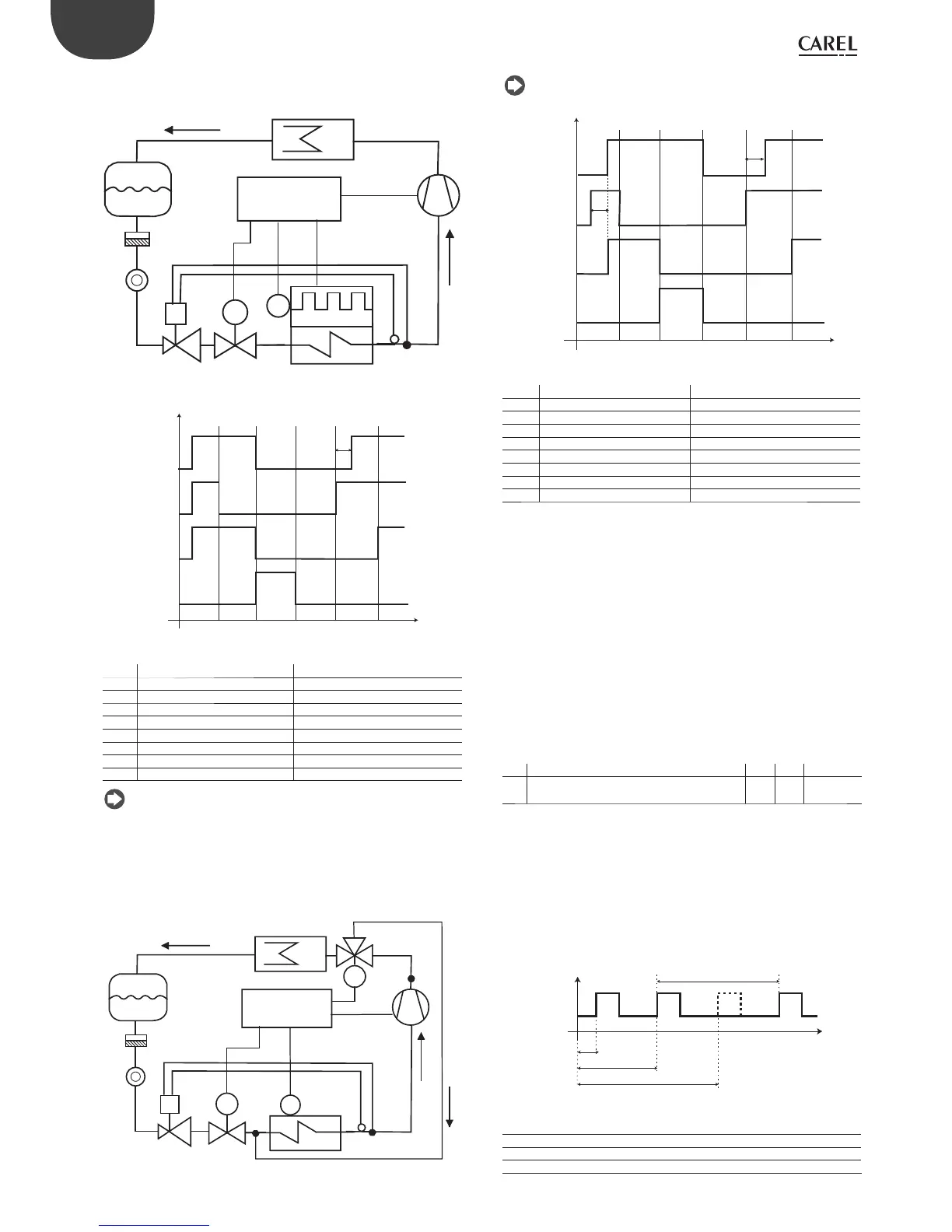

2. Hot gas defrost (d0 = 1, 3): duty cycle

The duty cycle refers to the default values of parameters F2 and F3.

C

L

CMP

T

V2

E

S2

V_Pd

M

M

V_def

S

F

SmartCella

Fig. 6.n

Note: the defrost output (DEF) is used to control the hot gas valve V_def.

ON

OFF

ON

OFF

t

CMP

V_Pd

ON

OFF

FAN

ON

OFF

V_def

(HOT GAS)

REFRIG PUMP

DOWN

DEF DRIP POST

DRIP

REFRIG

c8

c8

Fig. 6.o

Key

CMP Compressor Refrig Cooling

V_Pd Pump down valve Pump down Pump down stage

FAN Evaporator fan Def Defrost

V_def Hot gas valve Drip Dripping

E Evaporator Post drip Post-dripping

C Condenser S2 Defrost probe

V2 Thermostatic expansion valve L Liquid receiver

F Filter-drier S Liquid gauge

t Time

The defrost starts:

• by setting the event and the start mode, with a maximum of 8 defrosts

each day (parameters td1 to td8). The real time clock (RTC) must be

available;

• from the supervisor, which sends the defrost call to each controller via

the serial line;

• from the keypad.

The defrost ends:

• when the defrost probe measures a temperature greater than the end

defrost temperature dt1;

• when no defrost probe is used, the defrost ends after a maximum time,

set by parameter dP1.

Maximum time between consecutive defrosts

Par. Description Def Min Max UOM

dI Maximum time between consecutive defrosts

0 = defrost not performed

8 0 250 hr/

min

Tab. 6.k

Parameter dI is a safety parameter used to perform cyclical defrosts

every “dI” hours, even without the Real Time Clock (RTC). It is also useful

if the RS485 serial network is disconnected. At the start of each defrost,

irrespective of the duration, an interval starts being counted. If this

interval exceeds dI without a defrost being performed, one is started

automatically. The count is always active even if the controller is OFF.

Example: if there is an RTC fault, the defrost programmed by td3 is not

performed, and after the safety time dI a new defrost starts.

ON

OFF

DEF

t

td1

td2

dI

td3

Fig. 6.p

Key

dI Maximum time between consecutive defrosts

td1…td3 Programmed defrosts

DEF Defrost

t Time

Loading...

Loading...