13

ENG

“SmartCella manual” +0300084EN - rel. 1.2 - 28.03.2017

2.4 Installation

To install the controller, proceed as follows, with reference to the wiring

diagrams shown in the previous paragraphs:

1. connect the probes and power supply: the probes can be installed up

to a maximum distance of 10 m from the controller, using shielded

cables with a minimum cross-section of 1 mm². To improve immunity

to disturbance, use probes with shielded cables (connect only one end

of the shield to the earth on the electrical panel);

2. program the controller: as shown in the chapters “Commissioning” and

“User interface”;

3. connect the actuators: the actuators should only be connected after

having programmed the controller. Carefully check the maximum

capacities of the relays or three-phase contactors, as indicated in the

“technical specifi cations”;

4. serial network connection: all controllers are fi tted with a serial

connector for connection to the supervisor network via the serial

interface (IROPZ485*0 or serial board IROPZSER30). The secondary

of the transformers that supply the controllers must not be earthed.

If connection to a transformer with earthed secondary winding is

required, an insulating transformer must be installed in between.

Important: a separate transformer must be used for each controller,

- NEVER connect multiple controllers to the same transformer.

Warnings: avoid installing the controller in environments with the

following characteristics:

• relative humidity greater than 90% non-condensing;

• strong vibrations or knocks;

• exposure to continuous water sprays;

• exposure to aggressive and polluting atmospheric agents (e.g.: sulphur

and ammonia gases, saline mist, smoke) which may cause corrosion

and/or oxidation;

• strong magnetic and/or radio frequency interference (for example ,

near transmitting antennae);

• exposure to direct sunlight and the elements in general.

The following warnings must be observed when connecting the

controllers:

• incorrect connection of the power supply may seriously damage the

controller;

• use cable ends suitable for the corresponding terminals. Loosen each

screw and insert the cable ends, then tighten the screws and gently

pull the cables to check their tightness. When tightening the screws,

do not use automatic screwdrivers, rather adjust tool tightening

torque to less than 0.5Nm;

• separate as much as possible (by at least 3 cm) the probe signal and

digital input cables from inductive loads and power cables, to avoid

any electromagnetic disturbance. Never lay power cables and probe

cables in the same cable conduits (including those for the electrical

panels). Do not install the probe cables in the immediate vicinity of

power devices (contactors, circuit breakers or the like). Reduce the

length of the sensor cables as much as possible, and avoid spirals

around power devices;

• only use IP67 guaranteed probes as end defrost probes; place the

probes with the vertical bulb upwards, so as to facilitate drainage

of any condensate. Remember that thermistor temperature probes

(NTC) have no polarity, so the order the ends are connected in is not

important.

Cleaning the controller

When cleaning the controller do not use ethanol, hydrocarbons (petrol),

ammonia and by-products. Use neutral detergents and water.

2.5 Programming key IROPZKEY00/A0

The programming key can load up to 7 diff erent parameter confi gurations

onto the controller (the controller operating parameters plus 6 sets

of customisable default parameters). The keys are plugged into the

connector (4 pin AMP) available on the controllers. All the operations can

be performed with the controller off .

Fig. 2.j

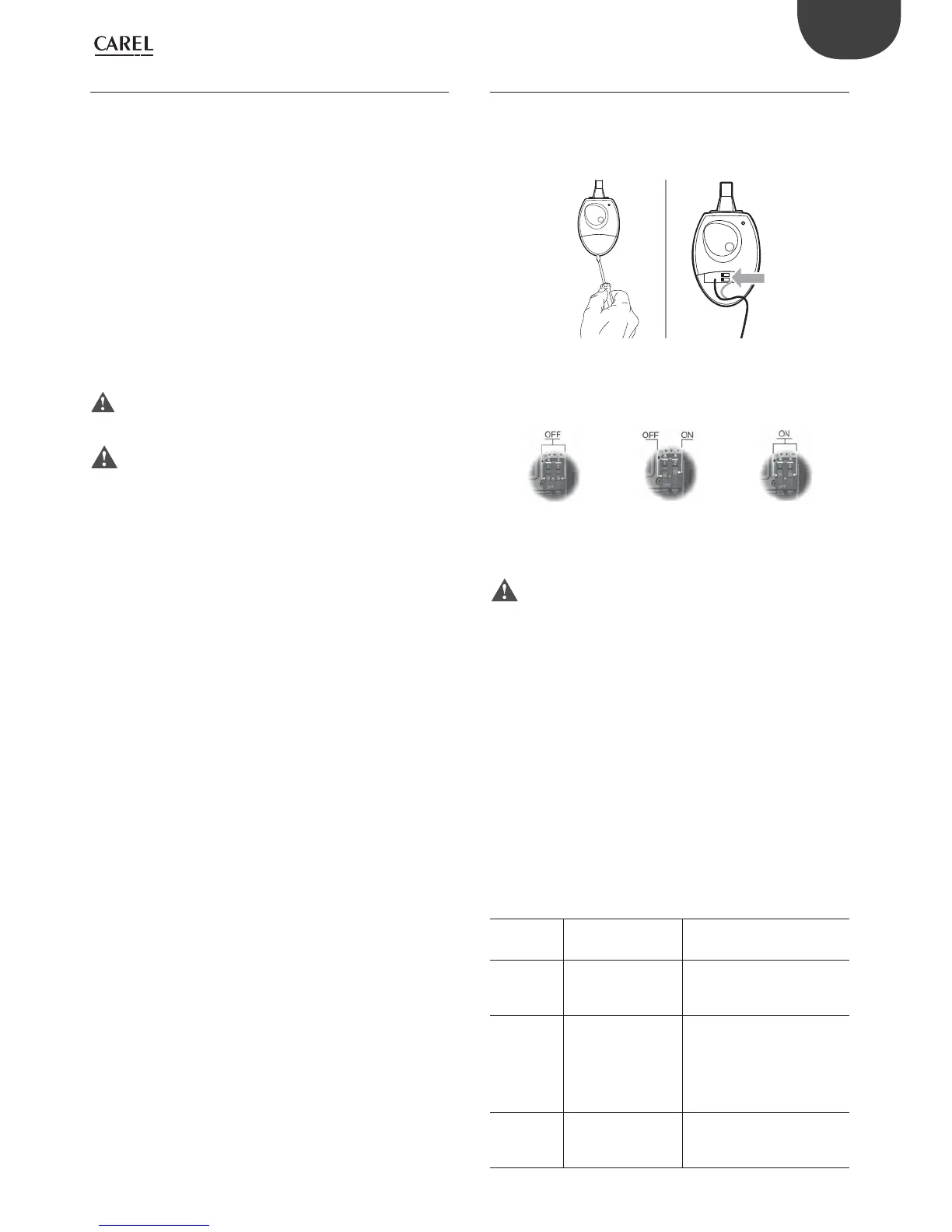

The functions are selected by setting the two dipswitches, accessible by

removing the battery cover.

UPLOAD DOWNLOAD EXTENDED DOWNLOAD

• load the parameters from a controller onto the key (UPLOAD);

• copy from the key to a controller (DOWNLOAD);

• extended copy from the key to a controller (EXTENDED DOWNLOAD).

Important: The parameters can only be copied between

controllers with the same part number. The UPLOAD operation can,

however, always be performed.

Copying and downloading the parameters

The following operations are used for the UPLOAD and/or DOWNLOAD

functions, simply by changing the settings of the dipswitches on the key:

1. open the rear cover on the key and position the 2 dipswitches according

to the desired operation;

2. close the rear cover on the key and plug the key into the connector on

the controller;

3. press the button and check the LED: red for a few seconds, then green,

indicates that the operation was completed correctly. Other signals

or the fl ashing of the LED indicates that problems have occurred: see

the table below;

4. at the end of the operation, release the button, after a few seconds the

LED goes off ;

5. remove the key from the controller.

LED signal Error Meaning and solution

Red LED

fl ashing

Batteries discharged at

start copy

The batteries are discharged,

the copy operation cannot be

performed. Replace the batteries.

Green LED

fl ashing

Batteries discharged

during copy or at end

of copy

During the copy operation or

at the end of the operation the

battery level is low. Replace the

batteries and repeat the operation.

Red/green

LEDs fl ashing

(orange signal)

Controller not

compatible

The parameter set-up cannot be

copied as the connected controller

model is not compatible. This error

only occurs for the DOWNLOAD

function; check the controller

P/N and run the copy only for

compatible models.

Red and green

LEDs on

Error in data being

copied

Error in the data being copied.

The EEPROM on the controller

is corrupted, therefore the data

cannot be copied to/from the key.

Loading...

Loading...