41

Phase Protection

The phase loss protection option will monitor the three-phase electrical

system to provide phas e r eversal and phas e loss protection.

Phase Reversal Protection

If the control senses an incorrect phase relationship, the relay (K1)

will be de-energized (opening its contact). If the phase relationship

is correct, the relay will be energized. The control has a self-bypass

function after a pre-set time. If the control determines that the three

phases stay in a correct relationship for 10 consecutive minutes, the

relay will stay energized regardless of the phase sequence of three

inputs as long as 24-VAC control voltage is applied. This

self-bypass function will be reset if all three phases are restored in a

phase loss event.

Phase Loss Protection

If the re verse rot ation board se nses any one of the thr ee phas e input s

has no AC volt age, the relay wil l be de--energized (opening its

contact). This prot ecti on is always active as long as 24-VAC c ontrol

voltage is appl ied, and is not affected by the self by-pass function of

the phase sequence moni t oring function. Howeve r, i n the event of

phase loss, the relay will be re -ene rgiz ed only if all thr ee phases are

restored and t he three pha s es are in t he correct se quence .

A red LED is provided to indicate the function of the board. See

the table below.

LED STATUS FUNCTION

On Continuously Relay contact closed (normal operation).

Blinking

Relay contact open (phase loss or phase

reversal has occurred) — No power will be

supplied to the control system.

Off 24---VAC control power not present (off).

Thermistor Troubleshooting

The SystemVut controller uses thermistors to sense temperatures

used to control operation of the unit. Resistances at various

temperatures are listed in Table 20. Thermistor pin connection

points are shown in the Major System Components section. The

general locations of the thermistors are shown the Major System

Components section.

Air Temperatures

Air temperatures are measured with 10K thermistors. This includes

supply-air temperature (SAT), outdoor-air temperature (OAT),

space temperature sensors (T55, T56, T59), and return air

temperature (RAT).

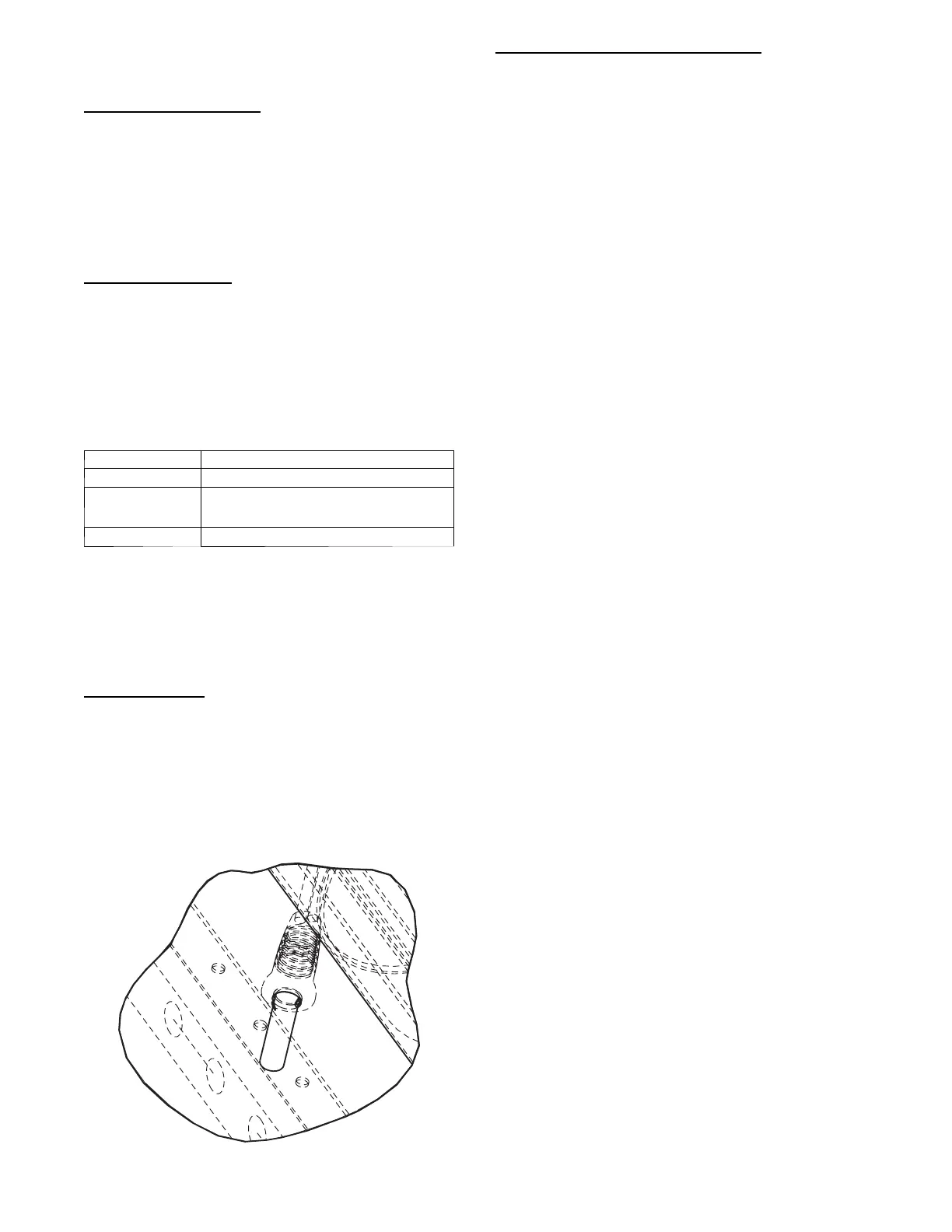

The supply air temperature (SAT) and outdoor air temperature

(OAT) thermistors use a snap-mount to attach through the unit

sheet metal panels. The snap-mount tabs must be flattened on the

tip end of the sensor to release for removal from the panel. (See

Fig. 20.) To reinstall, make sure the snap-mount tabs extend out.

C07015

Fig. 20 -- SAT and OAT Thermistor Mounting

Thermistor/Temperature Sensor Check

A digital volt-ohmmeter is required to perform this check.

Connect the digital volt-- ohmmeter across the appropriate

thermistor terminals at the J8 connector on the Main Base Board

(see Major System Components section).

Using the voltage reading obtained, read the sensor temperature

from Table 20 (on page 42).

To check thermistor accuracy, measure temperature at

probe location with an accurate thermocouple-type

temperature-measuring instrument. Insulate thermocouple to avoid

ambient temperatures from influencing reading. T e mperature

measured by thermocouple and temperature determined from

thermistor voltage reading should be close, within 5F if care was

taken in applying thermocouple and taking readings.

If a more accurate check is required, unit must be shut down and

thermistor removed and checked at a known temperature (freezing

point or boiling point of water) using either voltage drop measured

across thermistor at the J8 connector, or by determining the

resistance with unit shut down and thermistor disconnected from

J8. Compare the values determined with the value read by the

control in the Temperatures mode using the SystemVut display.

Sensor Trim

Corrective offsets can be applied to all the analog inputs. Trim can

be used as a form of calibration. The trim works by adding or

subtracting the specified amount on the specified analog input.

These corrections should only be use when a proper calibrated tool

is used to compare to the sensors reading. These corrections are

only applied to the local sensor values, a building systems (BAS)

communicating values will not account for these corrections. Use

the SERVIC E CALIBRATION menu on the SystemVu Di splay to

adjust these values.

Transducer Troubleshooting

The electronic control uses suction and discharge pressure

transducers to measure the pressure of the refrigerant circuits. The

pressure/voltage characteristics of these transducers are in shown in

Table 21 (on page 43) for suction transducers and Table 22 (on

pages 44 --45) for discharge transducers. The 5vdc power is applied

to legs A and B of the transducer and legs B to C represent the

signal voltage. To use the voltage drop table for troubleshooting,

read the voltage across A and B, then subtract the voltage reading

fro m B to C. The voltage drop can be looked u p in Table 21 and

Table 22 depending on the type of transducer. The accuracy of

these transducers can be verified by connecting an accurate

pressure gauge to the second refrigerant port in the suction and

discharge lines.

Loading...

Loading...