8

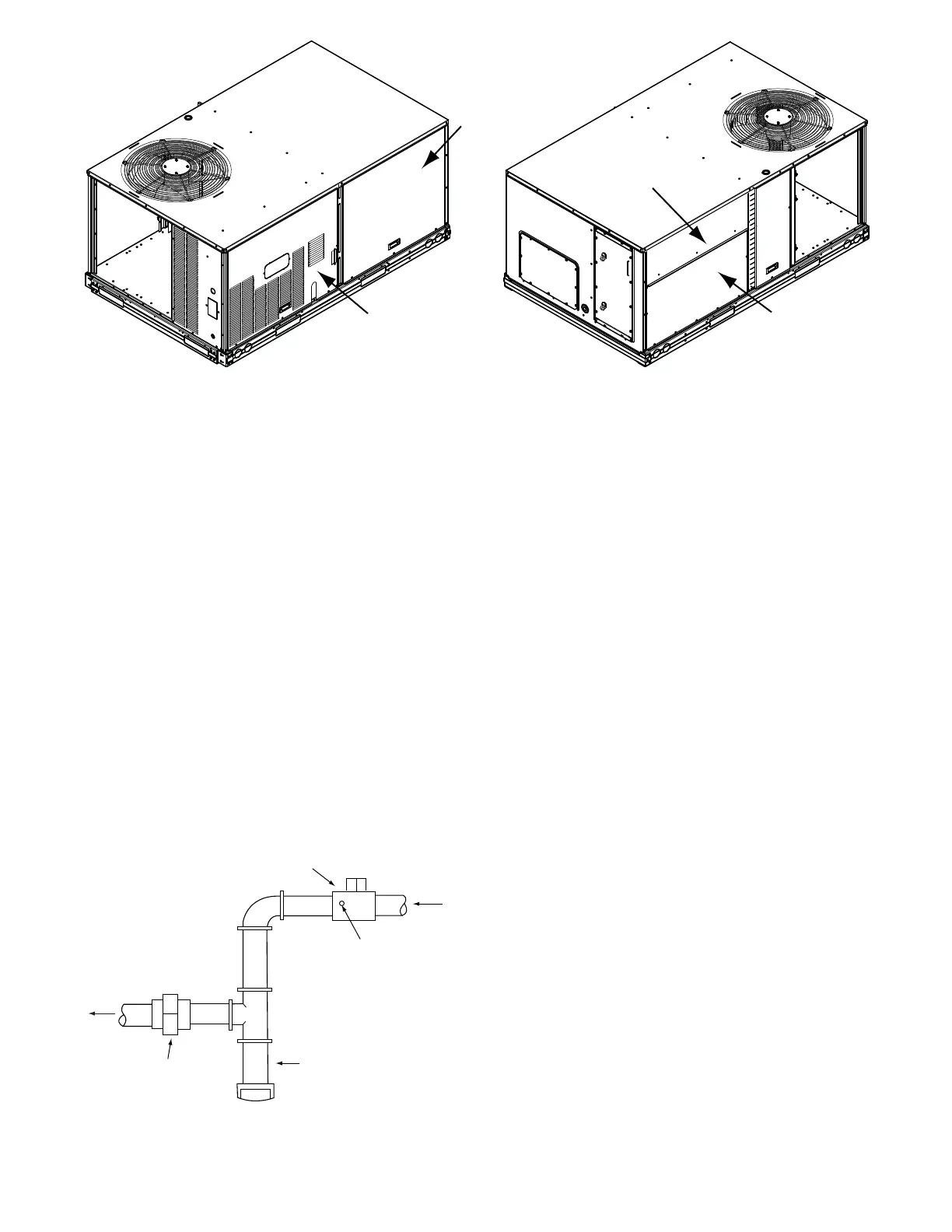

INDOOR

BLOWER

ACCESS

PANEL

CONTROL BOX

AND GAS SECTION

ACCESS PANEL

INDOOR COIL

ACCESS PANEL

FILTER

ACCESS PANEL

UNIT BACKUNIT FRONT

a48---9937

Fig. 6 -- Panel and Filter Locations

Return--Air Filters

Check that correct filters are installed in filter tracks (see Physical

Data table in unit Product Data). Do not operate unit without

return-air filters. Determine the filter change run time (DIRTY

FILTER TIME) to be set in the quick setup configurations menu.

Outdoor--Air Inlet Screens

Outdoor-air inlet screens must be in place before operating unit.

Accessory Installation

Check to make sure that all accessories including space thermostats

and sensors have been installed and wired as required by the

instructions and unit wiring diagrams.

Gas Heat (48FC and 48GC)

Inspect the gas heat section of the unit. Verify the number of

burners match the number of heat exchanger openings and the

burner assembly is properly aligned. If the orifices were changed

out for elevation or Liquid Propane purposes, verify proper

installation. Visually inspect other components in heat section.

Verify gas pressures before turning on heat as follows:

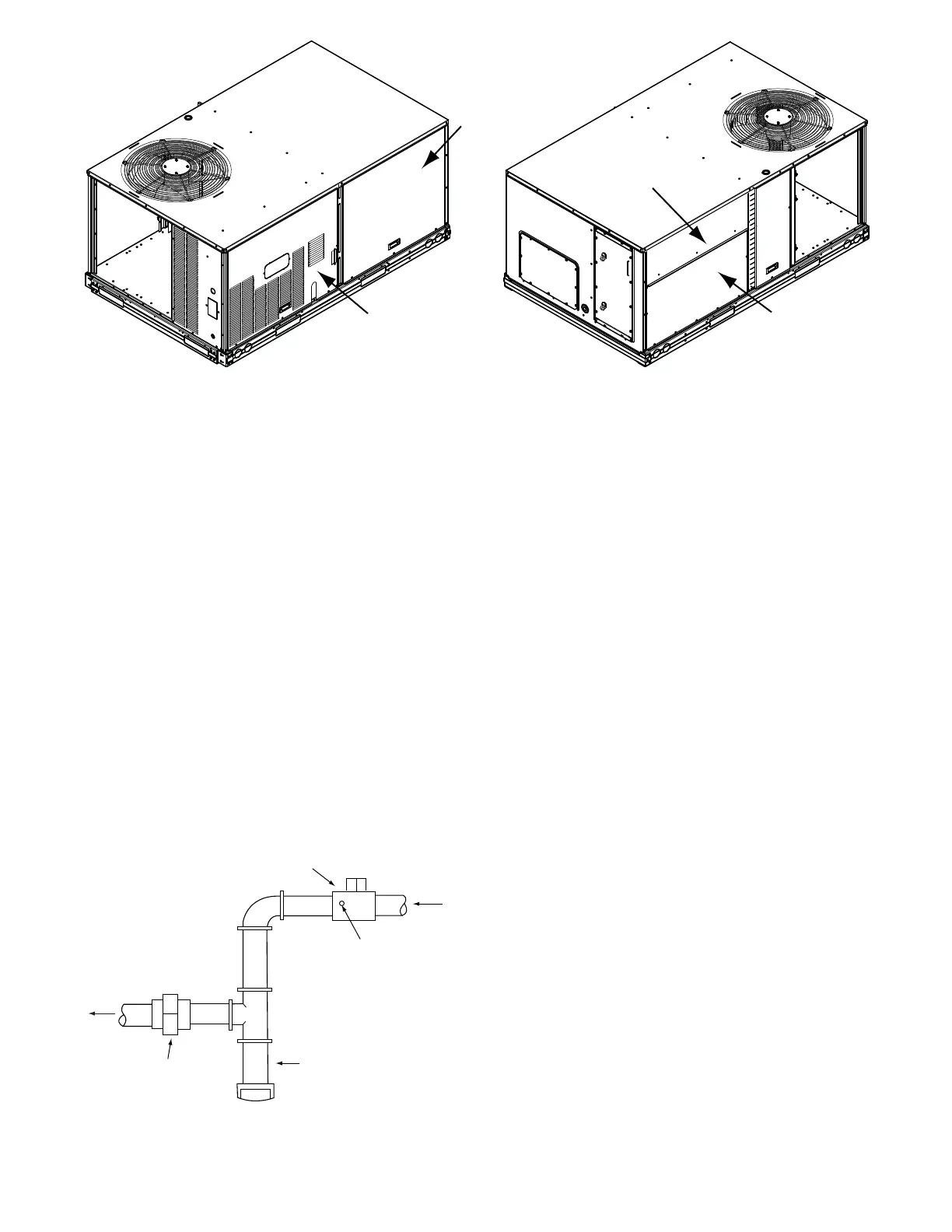

1. Close the field-supplied manual gas shut off valve, located

external to the unit.

2. Connec t a pressure gauge to the supply gas pressure tap,

located on the fi eld-supplie d ma nual ga s shut off valve (see

Fig. 7).

MANUAL GAS SHUT OFF VALVE

(FIELD SUPPLIED)

SUPPLY GAS

PRESSURE TAP

(1/8˝ NPT PLUG)

GAS

SUPPL

SEDIMENT TRAP

UNION

TO

UNIT

a48---9382

Fig. 7 -- Field Gas Piping

3. Connect a pressure gauge to the manifold pressure tap on

the burner assembly located inside the unit.

4. Open the field-supplied manual gas shut of f valve. Ente r

Service T est mode by setting TEST MODE to “ON” using the

SystemVut controller interface. Use the Service T est feature

to set HEAT 1 TEST to ON (f irst st age of hea t) us i ng the

SystemVu controller interface.

5. After the unit has run for several minutes, verify the supply

gas pressure is adequate per the base unit installation in-

structions. If not, adjust accordingly.

NOTE: Supply gas pressure must not exceed 13.0--in. wg.

6. Set HEAT 1 TEST to OFF using the SystemVu controller

interface.

7. Exit Service Test mode by setting TEST MODE to “OFF”

using the SystemVu controller interface.

CONTROLS QUICK SET--UP

The following information will provide a quick guide to setting up

and configuring t he 48/50FC and 48/50GC se ries units with

SystemVu controls. Unit controls are pre-configured at the factor y for

factory-installed options. Field-installed accessories will require

configuration at start-up. Initial System Startup is recommended for

initial start--up. Additionally, specific job requirements may require

changes to def ault c onfigura tion va l ues. See Appe ndix A and other

sections of these ins tructions f or more de t ails. Re fer to the Ma j or

System Component s or accessory installation instructions for specific

wiring detail.

Control Set Point and Configuration Log

During start up, accessory installation, and equipment service set

points and/or configuration changes might have to be made. When

setting set points or configuration settings, documentation is

recommend. The Control Set Point and Configuration Log starting

on page 132 should be filled out and left with the unit at all times,

a copy should also be provided to the equipment owner. A USB

jump drive can be used to back up the unit’s configurations. Refer

to the USB Operation section for details.

Initial Startup

Initial Startup refers to the first time this particular unit has a startup

performed. The SystemVu controller will continually display the

Initial Startup prompt until it is completed. To complete the initial

startup you must complete the Quick Setup, Network Setup, and

the System Auto Test.

Loading...

Loading...