SHANDONG CARTER HEAVY INDUSTRY MACHINERY CO., LTD.

44

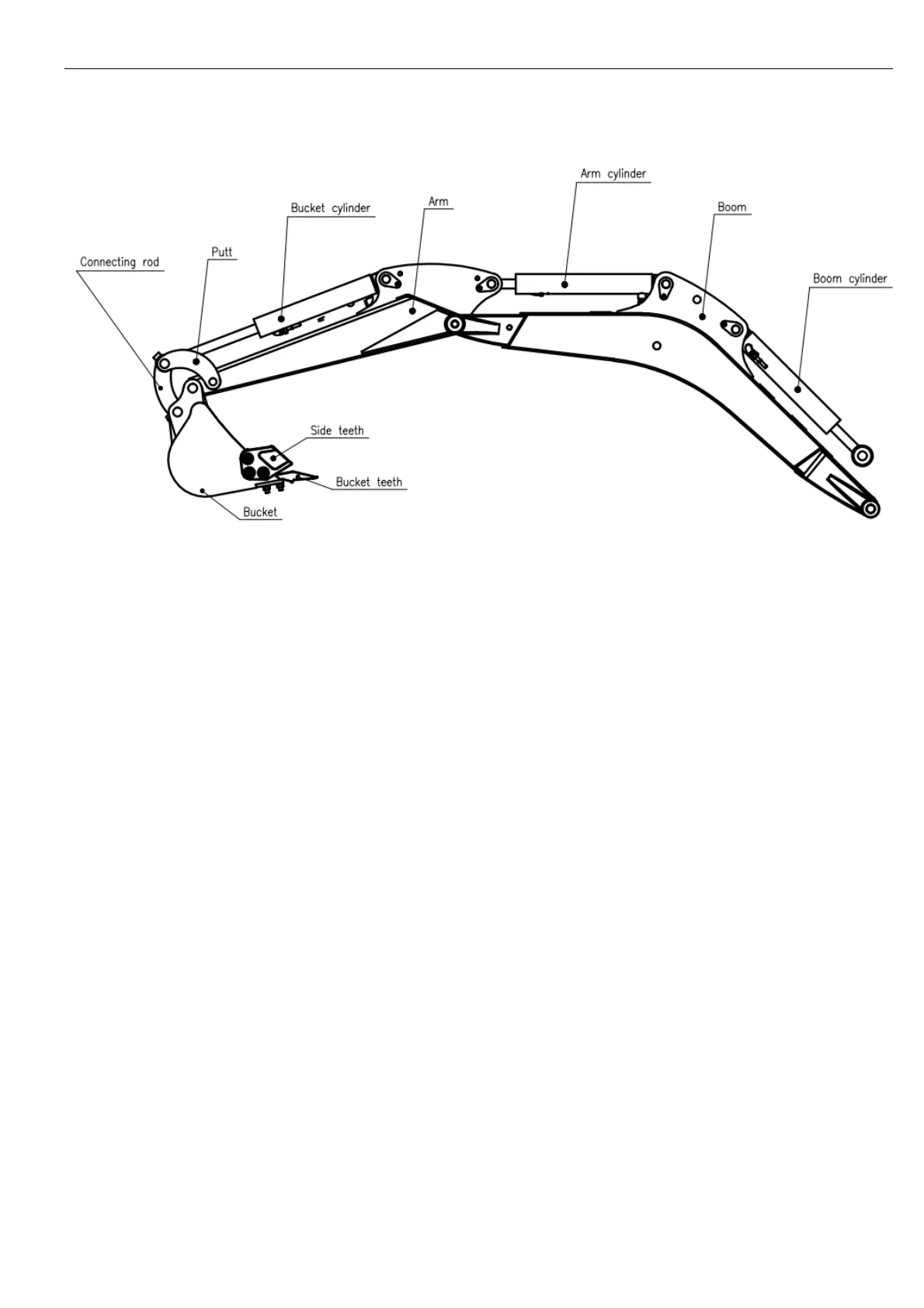

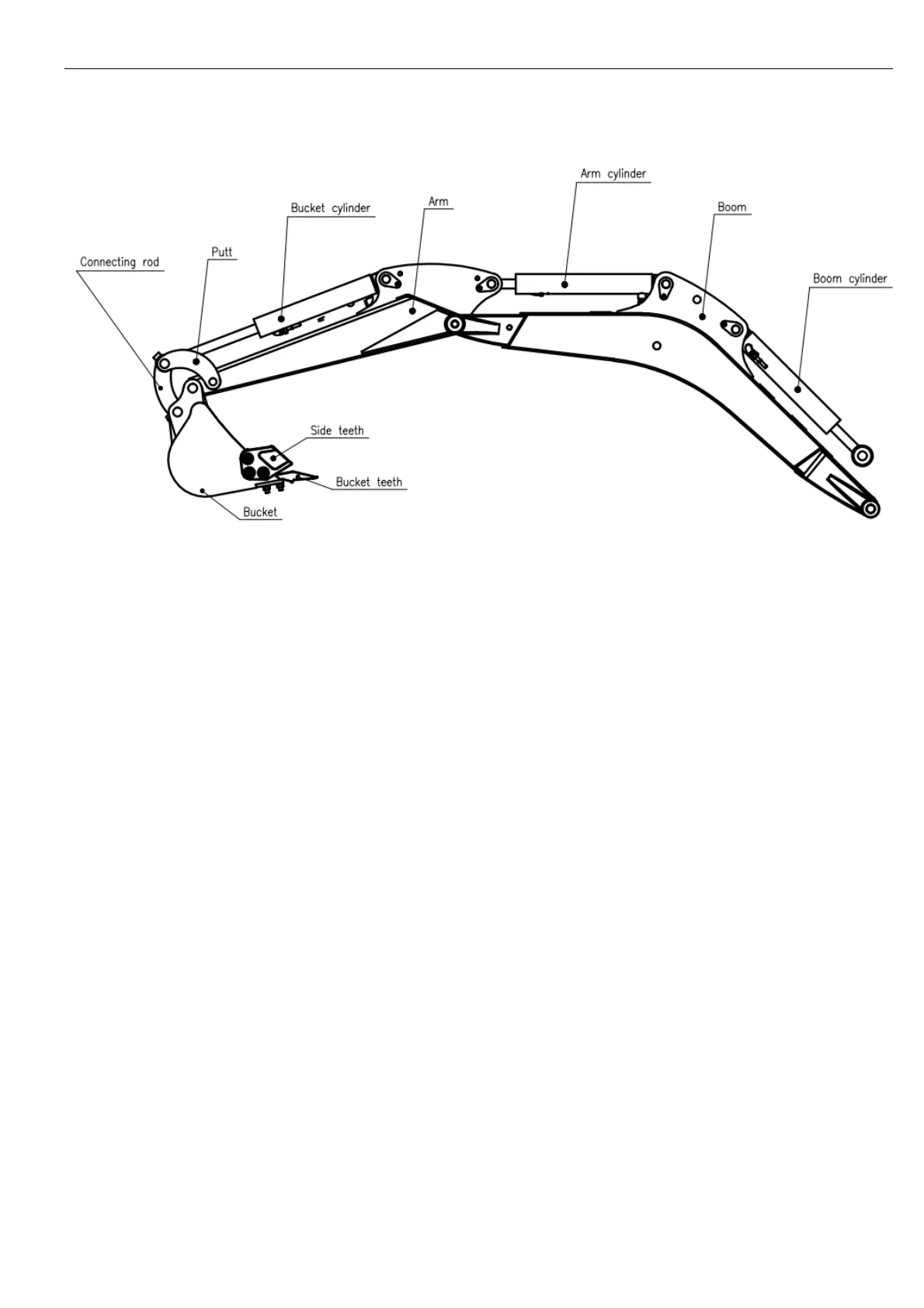

c. Bucket

1.Basic requirements

1) The longitudinal profile of bucket meets the law of motion of various materials inside of bucket,

facilitating the material flow and minimizing the loading resistance and thus fulfilling thebucket.

2)

Bucket teeth are mounted to increase the linear specific pressure of bucket onto material, with unit

cutting resistance relatively low and easing to cut in and break soil. In addition, the teeth are resistant to

wear and easy to replace.

3)

The load is easy to get off, shortening the unloading time and increasing the effective capacity of

bucket.

2.Structure

Bucket shape and size for backhoe are highly related to work objects. In order to meet various excavation, one

excavator could be equipped with multiple types of buckets, with backhoe most popular. Bucket teeth could be

mounted with rubber pins and bolts

Connection between bucket and hydraulic cylinder is of linkage mechanism, with bucket directly articulated

with hydraulic cylinder, which drops the rotation angle of bucket but enables the work torque to change

greatly.

Loading...

Loading...