SHANDONG CARTER HEAVY INDUSTRY MACHINERY CO., LTD.

62

5. Reassembly

Clean all parts before assembly. Repair any scratches or dents. Take special precautions against dirt and dust.

Parts with rust-preventive coatings must be assembles only after removing the corting.

Separated parts must be correctly reassembled using alignment marks.

As a rule, use a press to reassembled bearings, bushing and oil seals. Use pads when using a hamme

r.

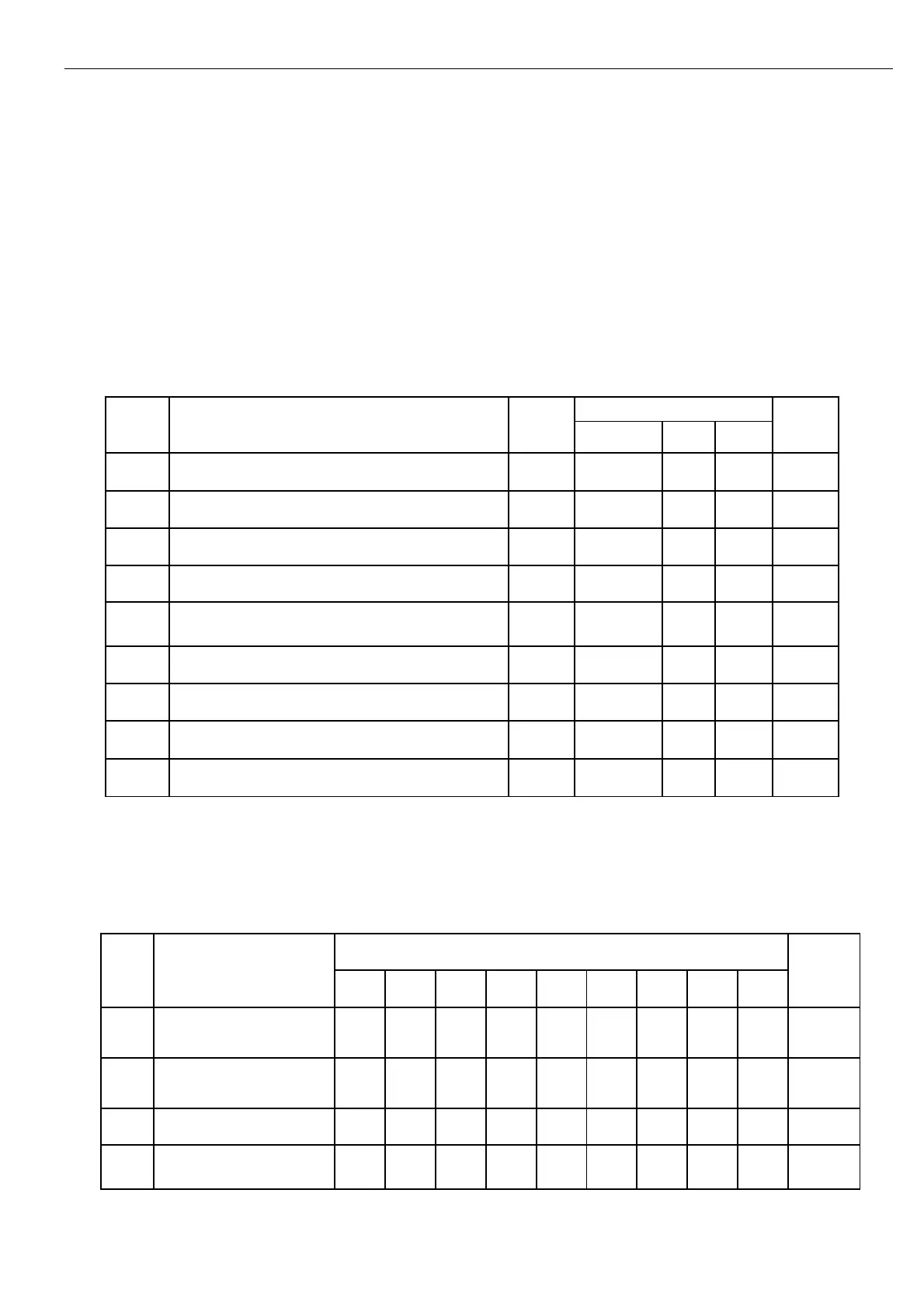

5.2 Daily inspection and maintenance

S/N Item Quantity

Interval (h)

Remark

everyday 20 100

1 Check the engine oil level in sump

1

★

2 Check the hydraulic oil level in hydraulic oil tank

1

★

3 Check the fuel level in tank

1

★

4 Check if the fuel pipe is leaked or cracked

----

★

5

Check the oil-water separator to completely drain,

any water or sediment out

1

★

6 Check the work equipment pivots

----

★

7 Check if the hydraulic hose and the pipeline leak

----

★

8 Check if the bucket teeth is worn or loosened.

3+2

★

9 Check the bolts and nuts for tightening torque

----

★

Note: ★: Maintenance interval under normal conditions

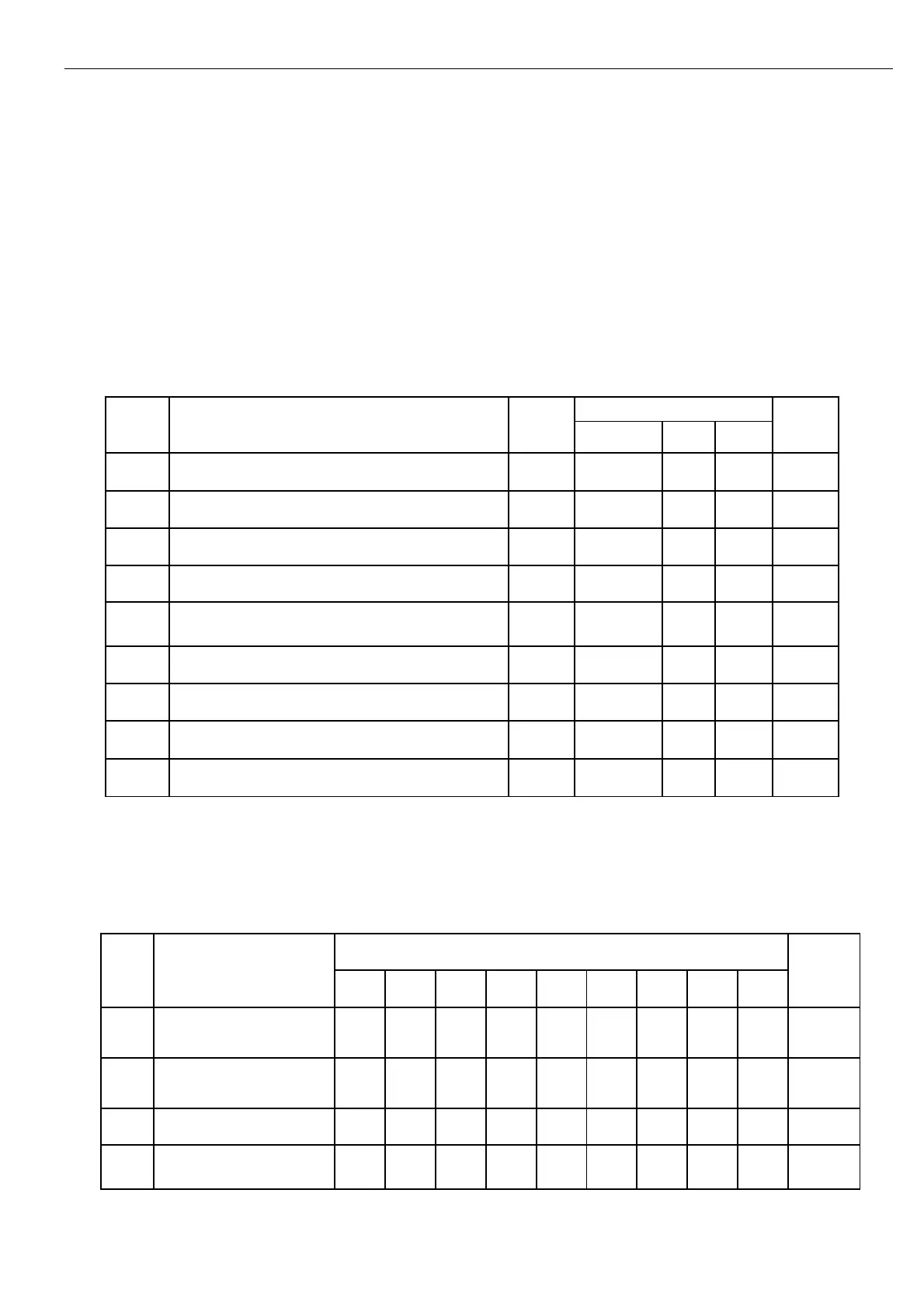

5.3 Periods of overhaul, medium and minor repair

S/N

Maintenance items

Interval (h)

Remark

50 100 250 500 1000 1500 2000 2500 4000

1

Greasing of slewing

bearing

★

2

Greasing of slewing

bearing gears

★

3 Change the engine oil ●

★

4

Change the engine oil

filter elements

●

★

Loading...

Loading...