SHANDONG CARTER HEAVY INDUSTRY MACHINERY CO., LTD.

76

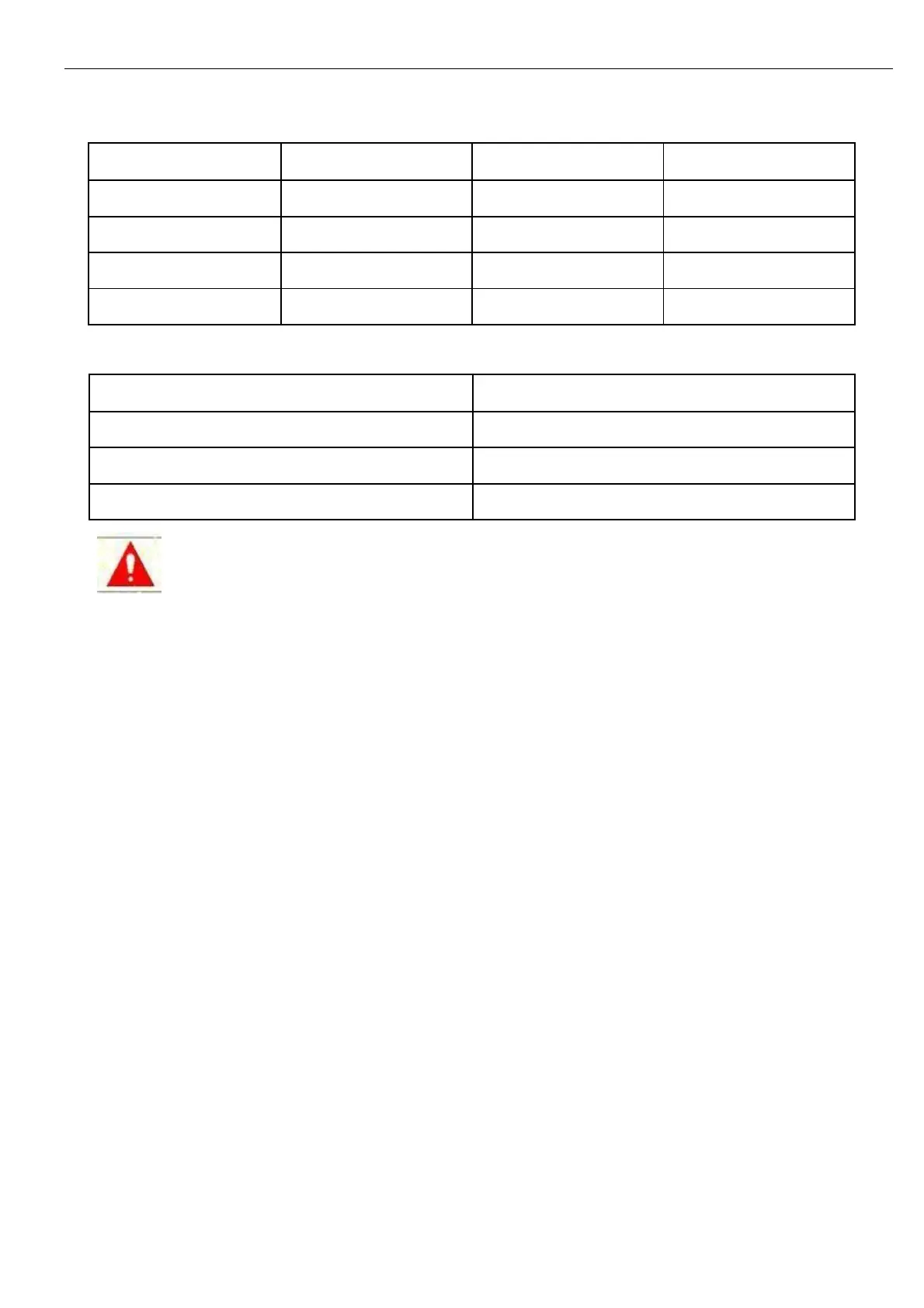

Metric bolts and nuts

Thread dimensions Standard torque (N.m) Thread dimensions Standard torque (N.m)

M6 12±3 M14 160±30

M8 28±7 M16 240±40

M10 55±10 M20 460±60

M12 100±20 M30 1600±200

2. Torque of main components: (N.m)

Thread dimensions Recommended torque

M12 bolts fixing the traveling motor 120±10

M16 bolts fixing the slewing bearing 325±15

M16 bolts fixing the swing mechanism 325±15

Important:

1.

Before installed, the bolts and nuts should be cleaned.

2.

Grease the bolts and the nuts (such as the white zinc b able to be dissolved to lubricant), so as to stabilize their

abrasion coefficient.

3.

The counterweight bolts should be kept tightened up.

Caution: all the tightening torques should be expressed with kgf.m.

For example: use a wrench with 1m long to tighten the bolts and nuts, and apply 12kgf of force to the end of

wrench, generating the following torque:

1m×12kgf=12kgf.m To

generate the same torque with 0.25m wrench: 0.25m×y=12kgf.m Needed

force: y=12kgf.m/0.25m=48kgf

Loading...

Loading...