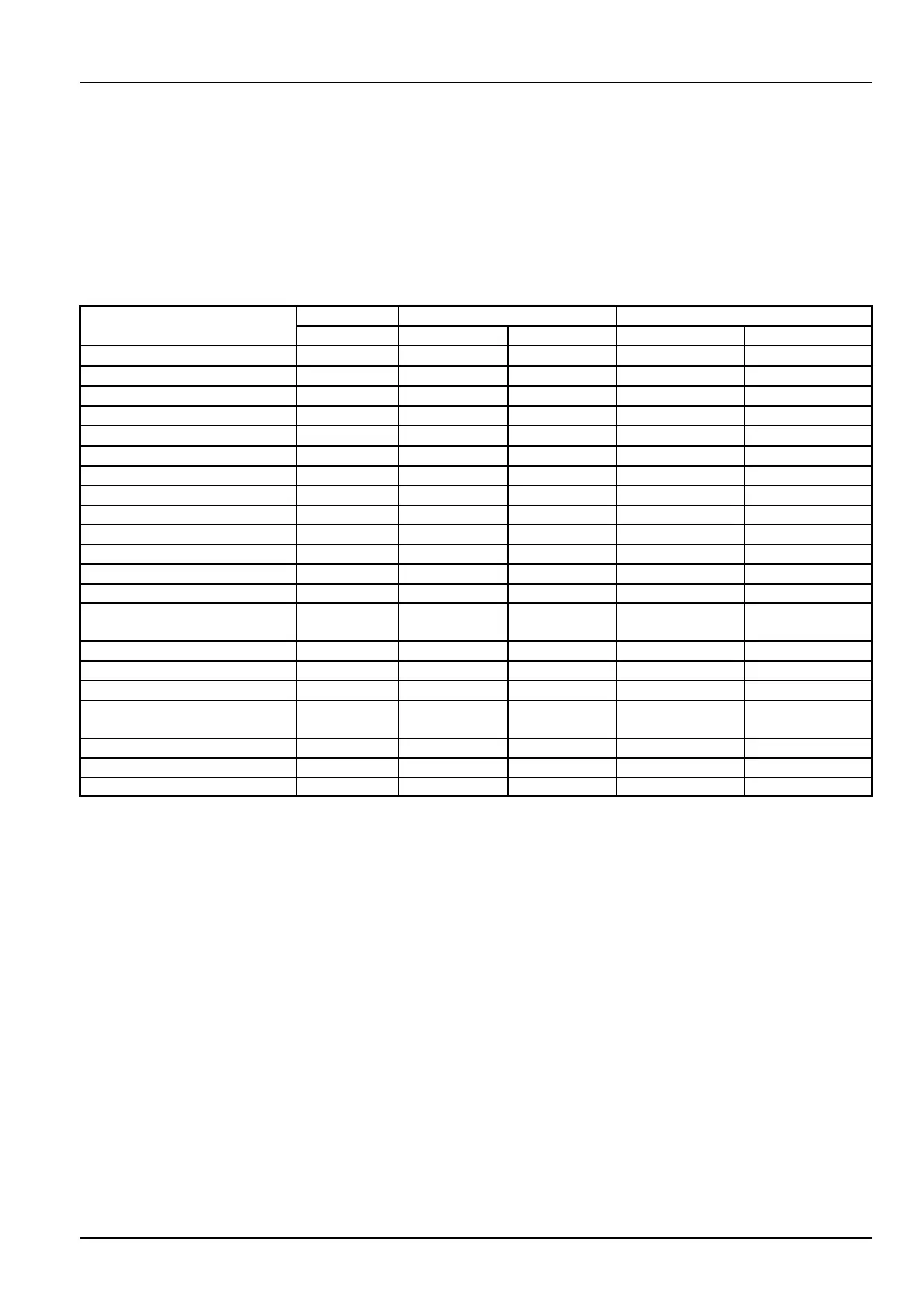

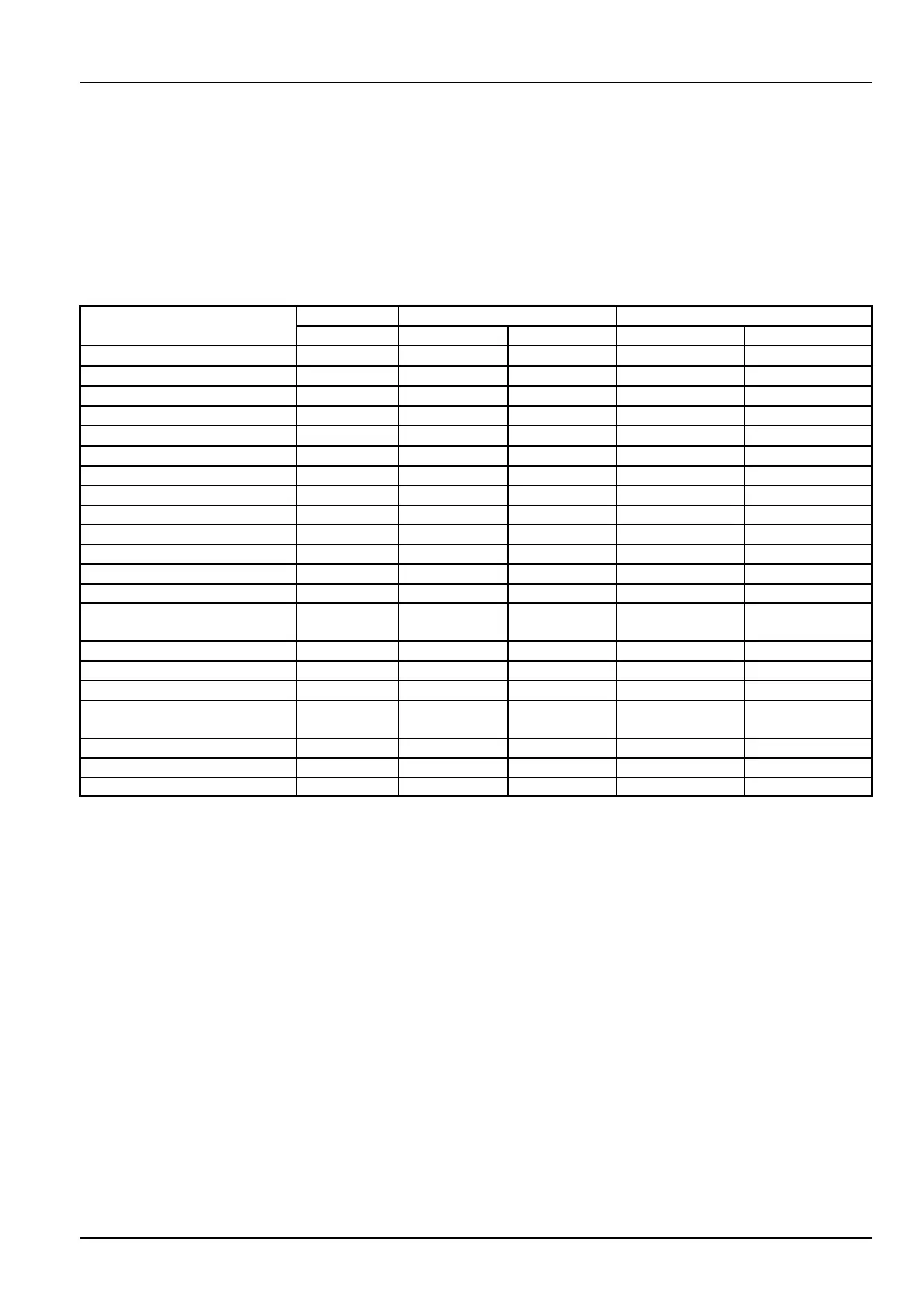

6-MAINTENANCE

Torquespecications

Servicespecications

Check:Every250hours(aftertherst50hoursduringtherun-inperiod)

Attheendofeachworkingday,checkallmountingnutsandscrewsfortightnessandtightenifnecessary.Makesure

nohardwareitemsaremissing.Replacethem,ifnecessary.

Torquespecicationspercomponent

Screw

Wrench

Torquesetting

Component

(Ø)

mm

inNm

lbft

Travelreductiongear(*)

M16240.9267–312197–230

Drivesprocket(*)

M16240.9267–312197–230

Idlerwheel(*)

M16240.9267–312197–230

Upperroller(*)

M16240.9267–312197–230

Lowerroller(*)

M16240.9267–312197–230

Chainguide(*)

M16240.9267–312197–230

Trackpad

M16240.9373–451276–332

Counterweight

M30461.81335–1550985–1143

TurntableM16240.9280–312207–230

Swingreductiongear(*)

M16240.9280–312207–230

Engine(*)

M12190.7109–12781–93

Enginemount(*)

M16240.9265–314196–231

RadiatorM12190.764–7348–54

Hydraulicpump(*)

M16

14(Hexagon

wrench)

0.6(Hexagon

wrench)

223–247165–182

Hydraulicreservoir(*)

M16240.9233–276172–203

Fueltank(*)

M16240.9233–276172–203

Controlvalve(*)

M16240.9267–312197–230

Hydraulicswivel(Lockingbar)

(*)

M12190.789–10766–78

Hydraulicswivel(Joint)(*)

M12190.7109–12781–93

Cab

M16240.9149–173110–127

BatteriesM10170.720–2915–21

NOTE:UseLoctite262,ortheequivalent,onscrewsmarked(*).

6-77

Loading...

Loading...