Model 55,75,90, & HMC FLEX-AUGER Installation

13

MA1702D

The FLEX-AUGER Delivery System includes two 45 degree elbows as standard equipment. These elbows are

used to make the sloping portion of the auger line at the feed bin, and elsewhere in the system if necessary. If

additional elbows are required, they should be ordered separately. Figure 4 shows how the elbow can be cut into

shorter sections.

1.Determine where the entrance hole for the auger tube must be located on the building and cut it.

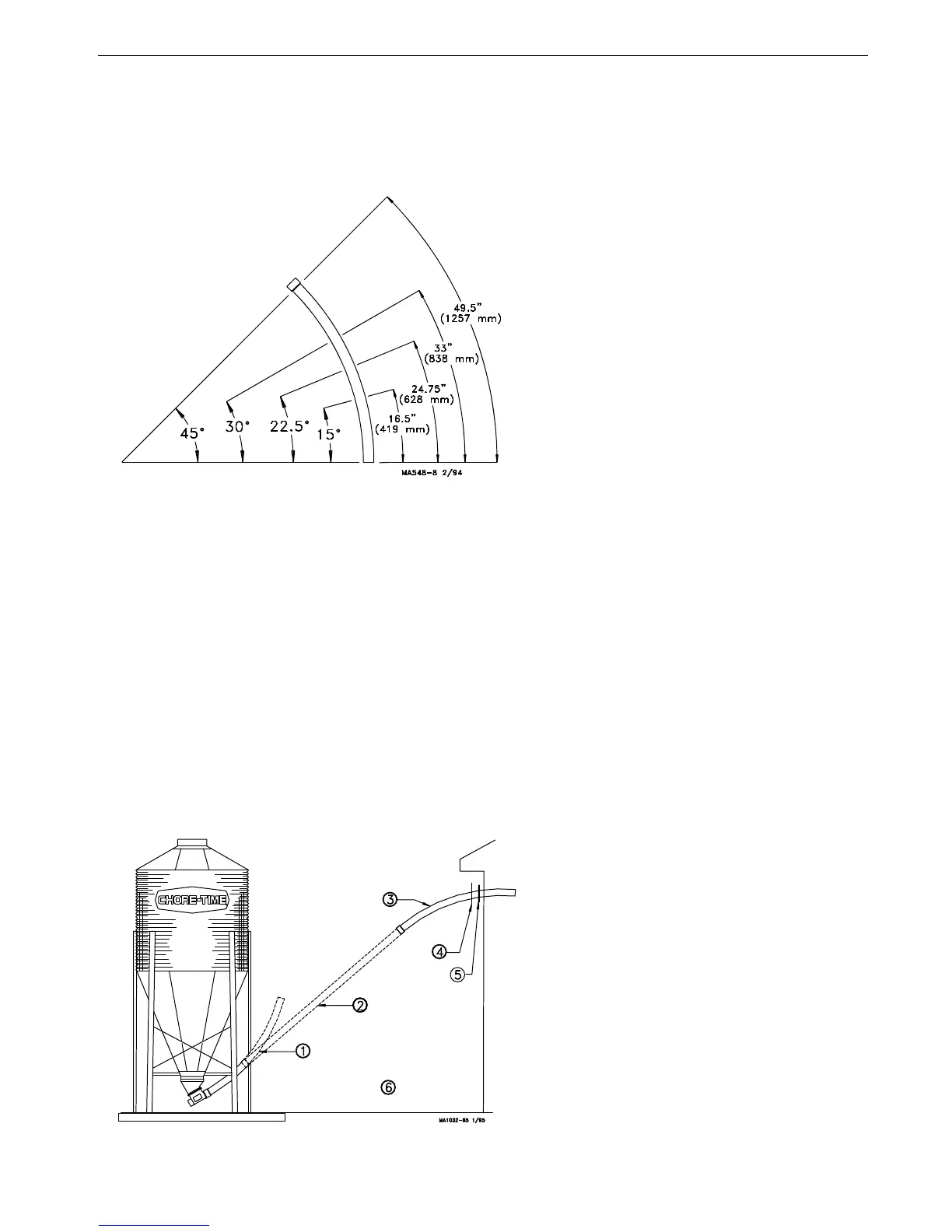

2.Cut the elbow used where the auger enters the building (if necessary). Slide the seal ring and neoprene seal

over the straight end of the elbow and place it in the hole cut in the building, with the belled end outside the

building. (See Figure 5).

3.Model 75, 90, & HMC: Slide the belled end of the elbow or auger tube over the outlet end of the boot. A

clamp is provided to secure the elbow or auger tube to the boot.

Model 55: Install the Model 55 Stub Tube over the outlet end of the boot. A clamp is provided to secure the

Stub Tube to the boot.

Slide the belled end of the first elbow or auger tube over the stub tube.

4.Place the end of a straight section of tube inside the belled end of the elbow in the building. Hold the straight

section of auger tube so that it touches the elbow on the boot. Mark the spot where the tube aligns with the

"boot" elbow and cut the elbow at that point.

5.Place the belled end of the auger tube over the end of the elbow just cut, and hold the tube against the top

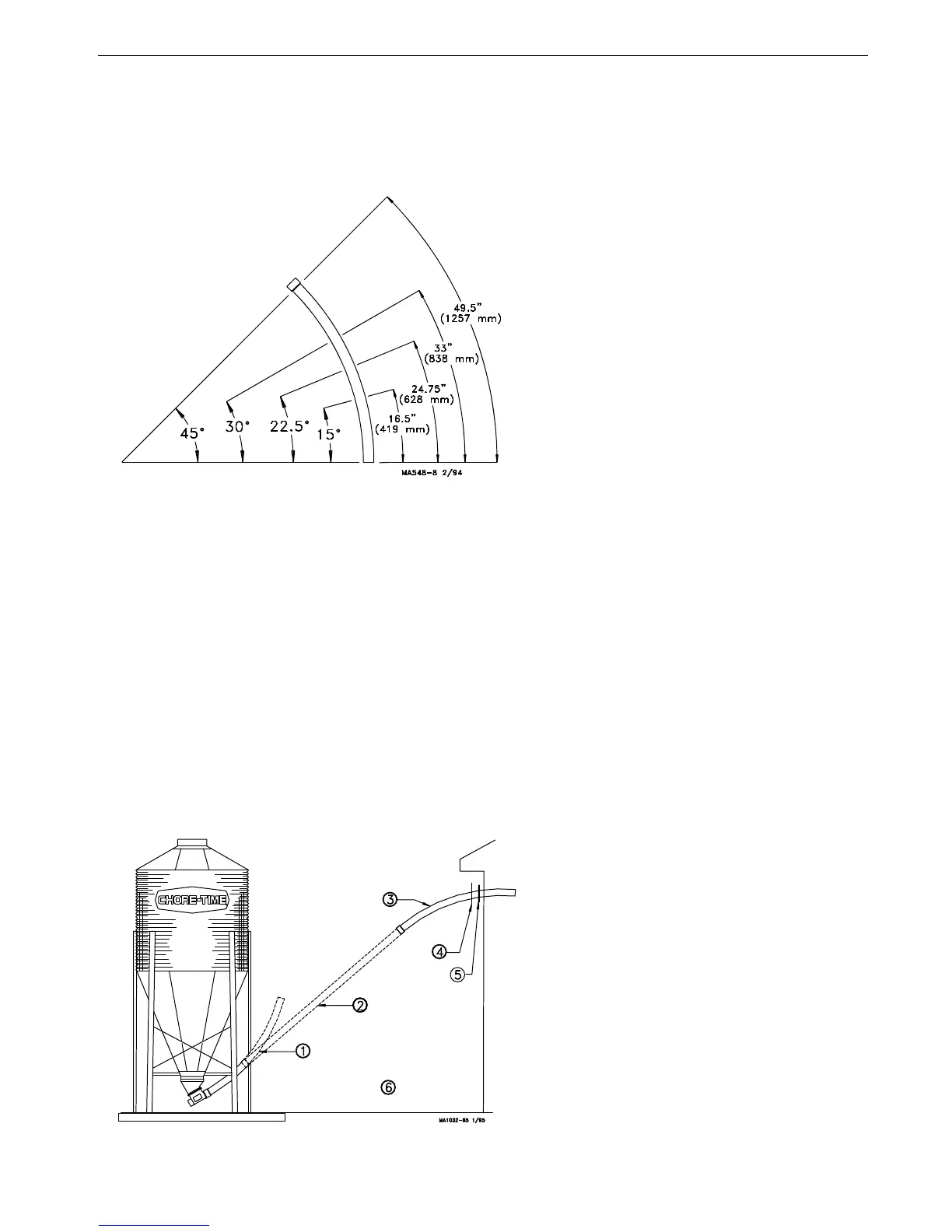

15 Degree Elbow .........16.5" or 419 mm

22.5 Degree Elbow ......24.75" or 628 mm

30 Degree Elbow .........33" or 838 mm

45 Degree Elbow .........49.5" or 1257 mm

These dimensions are measured along the

long, outside curve of the elbow. They do

not include the belled end of the elbow in

the measurement.

Figure 4.PVC Elbow Cutting Guidelines

Key Description

145° Elbow

2 Auger Tube

345° Elbow

4 Seal Ring

5 Neoprene Seal

6 Note: Belled end of elbows

and auger tubes should be

towards boot.

Figure 5.Elbow Installation outside the building

Loading...

Loading...