16—ENGINE

CHRYSLER SERVICE MANUAL

properly positioned, width of intake seats

should be y

16

to %

2

inch. The width of exhaust

seats should be %

4

to y

16

. When valves and

seats are reground, the position of valve in

head is changed, shortening operating length

of hydraulic tappet. This means that plunger is

operating closer to its bottomed position, and

less clearance is available for thermal expan-

sion of valve mechanism during high speed

driving. Design of plunger travel includes a

safety factor for normal wear and refacing of

valves and seats. The dimension from valve

spring seat in head to valve tip should be

checked with gauge Tool C-3436 for SpitFire

Engines and gauge Tool C-3061 for FirePower

Engines, (Figs. 17 and 18).

The end of cylindrical gauge and bottom of

slotted area represent maximum and minimum

allowable extension of valve stem tip beyond

spring seat. If tip exceeds maximum, grind to

approach, but do not go below minimum allow-

able on gauge.

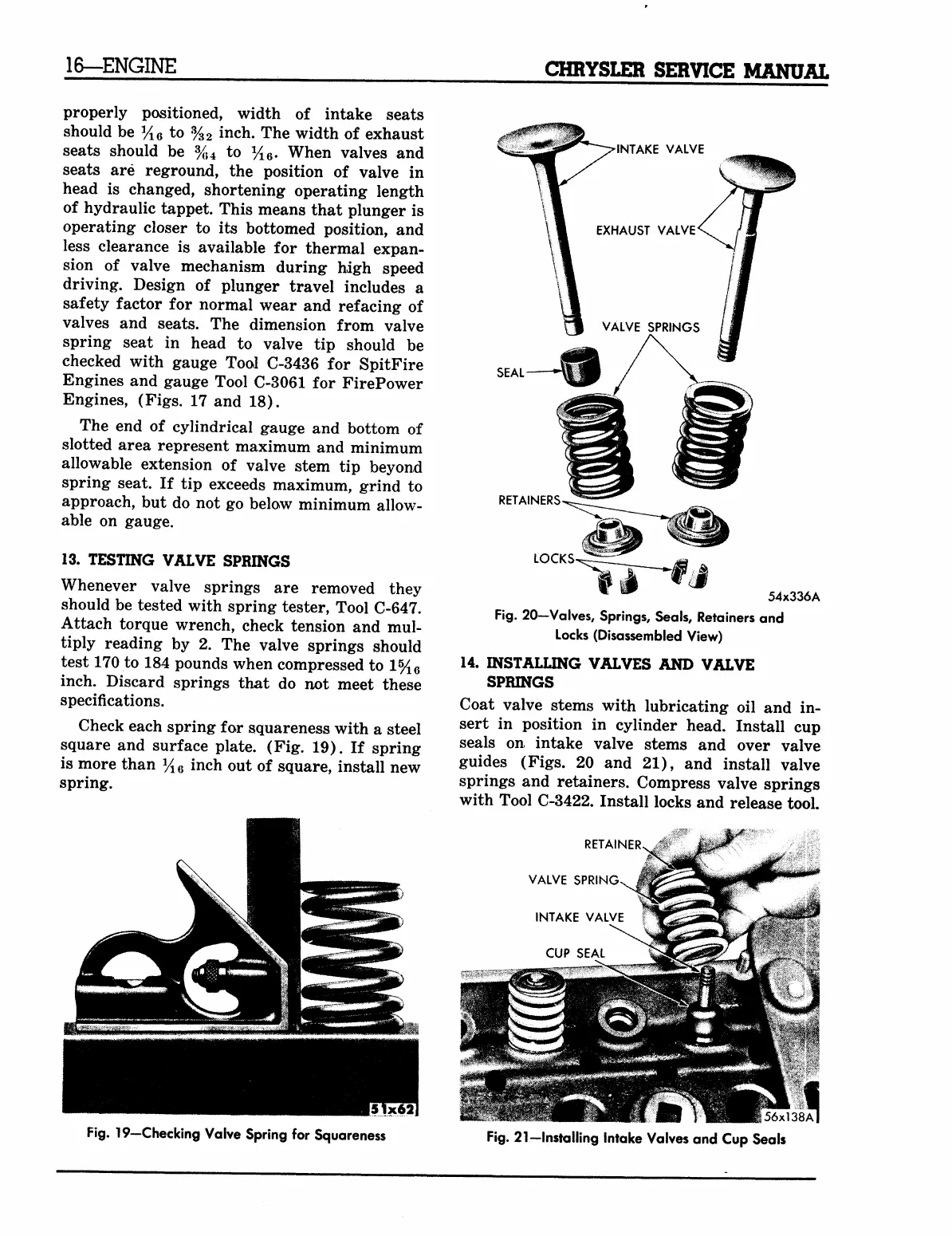

13.

TESTING VALVE SPRINGS

Whenever valve springs are removed they

should be tested with spring tester, Tool C-647.

Attach torque wrench, check tension and mul-

tiply reading by 2. The valve springs should

test 170 to 184 pounds when compressed to 1%

6

inch. Discard springs that do not meet these

specifications.

Check each spring for squareness with a steel

square and surface plate. (Fig. 19). If spring

is more than y

1Q

inch out of square, install new

spring.

SEAL

RETAINERS

LOCKS

w

54x336A

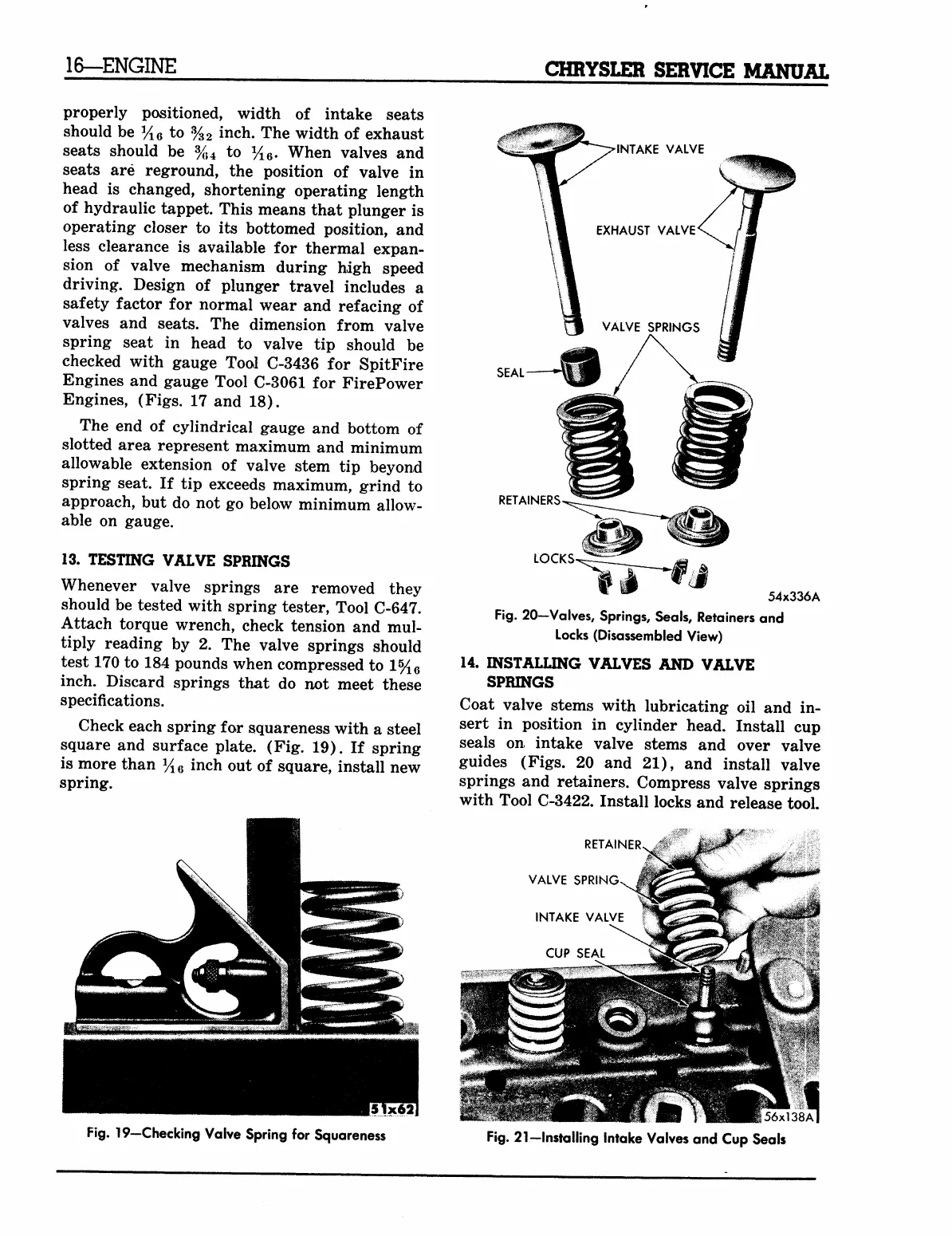

Fig.

20—Valves, Springs, Seals, Retainers and

Locks (Disassembled View)

14.

INSTALLING VALVES AND VALVE

SPRINGS

Coat valve stems with lubricating oil and in-

sert in position in cylinder head. Install cup

seals on intake valve stems and over valve

guides (Figs. 20 and 21), and install valve

springs and retainers. Compress valve springs

with Tool C-3422. Install locks and release tool.

RETAINER

VALVE SPRING

INTAKE VALVE

CUP SEAL

Fig.

19-Checking Valve Spring for Squareness

Fig.

21-lnstalling Intake Valves and Cup Seals

MyMopar.com

Loading...

Loading...