27

M-Series Maintenance - Recirculation Valve Timing

SEALANT MATERIAL RECIRCULATION VALVE:

The material sealant pumping system relies on a mechanical valve to direct the flow of material either

to the application hose and wand or in recirculation mode back to the tank. This valve is operated by a

hydraulic actuator and is connected to the recirculation valve shaft by a clamp and two set screws.

This system is intentionally designed to slip when under extreme force to prevent damage to the valve

or the hydraulic actuator. If the system is activated when cold material is inside the valve the actuator

may try to operate the valve and not be able to move due to the cold material impeding proper

operation of the valve interior. Thus the clamp will slip on the shaft and be out of time with the proper

operation to apply sealant or recirculate material back to the tank.

Correct Position for

Material Flow Between Application and Recirculation:

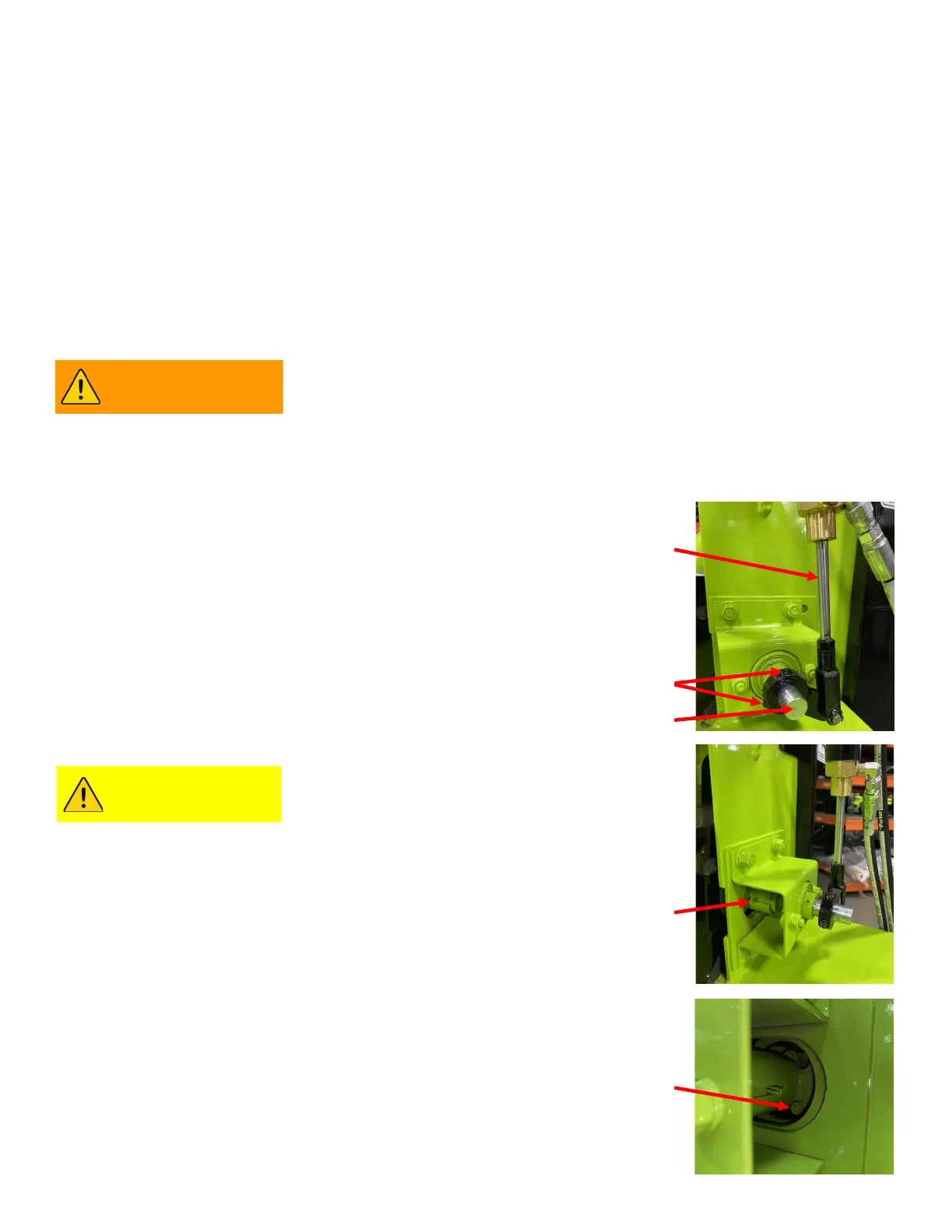

a) The first photo shows the hydraulic actuator (A) fully extended

and in the recirculation position. This is the correct position for

the valve and hydraulic actuator when the system is not calling

for sealant to the applicator hose and wand.

b) The second photo again shows the recirculation valve in the

correct position for recirculation as indicated by the roll pin (B)

being in the horizontal (9 o’clock - 3 o’clock) position. When the

hydraulic actuator retracts it turns the valve shaft in a counter

clockwise direction and the roll pin (B) will be in a vertical (12

o’clock - 6 o’clock) position.

INSTRUCTIONS FOR RESETTING THE TIMING OF THE

RECIRCULATION VALVE:

It may be necessary to run the melter up

to temperature in order to successfully

operate the valve when making this

timing adjustment. Extreme caution

must be taken when working around hot material and hot melter

machine parts.

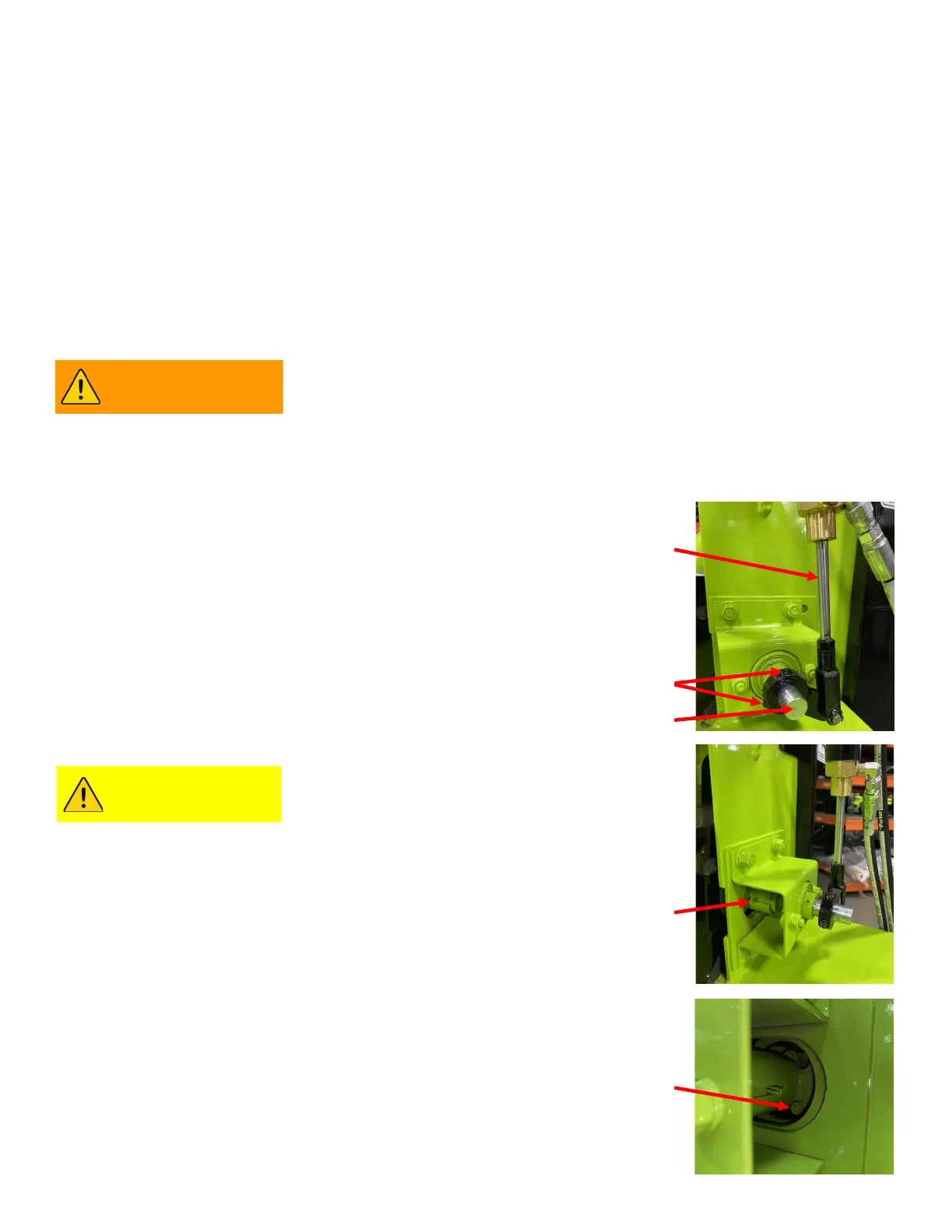

1) Loosen the two hex head screws (C) on the clamp from the

hydraulic actuator to the recirculation valve shaft.

2) Using a locking plyers or pipe wrench rotate the recirculation

valve shaft (D) until the roll pin is in the correct orientation -

horizontal (9 o’clock - 3 o’clock) position.

3) With the hydraulic actuator extended in the recirculation position

and the roll pin on the valve shaft in the horizontal (9 o’clock - 3

o’clock) position, tighten the two hex head screws (C) on the

clamp, torque to 22 ft. lbs.

4) In some rare occasions the recirculation valve limit set screw

will need to be adjusted . The limit screw is shown in the photo

as (E).

(B)

(A)

(C)

(D)

(E)

The melter operates at elevated temperatures which can cause

burns. Be sure the sealant material is cool before performing

maintenance.

WARNING

CAUTION

Loading...

Loading...