14

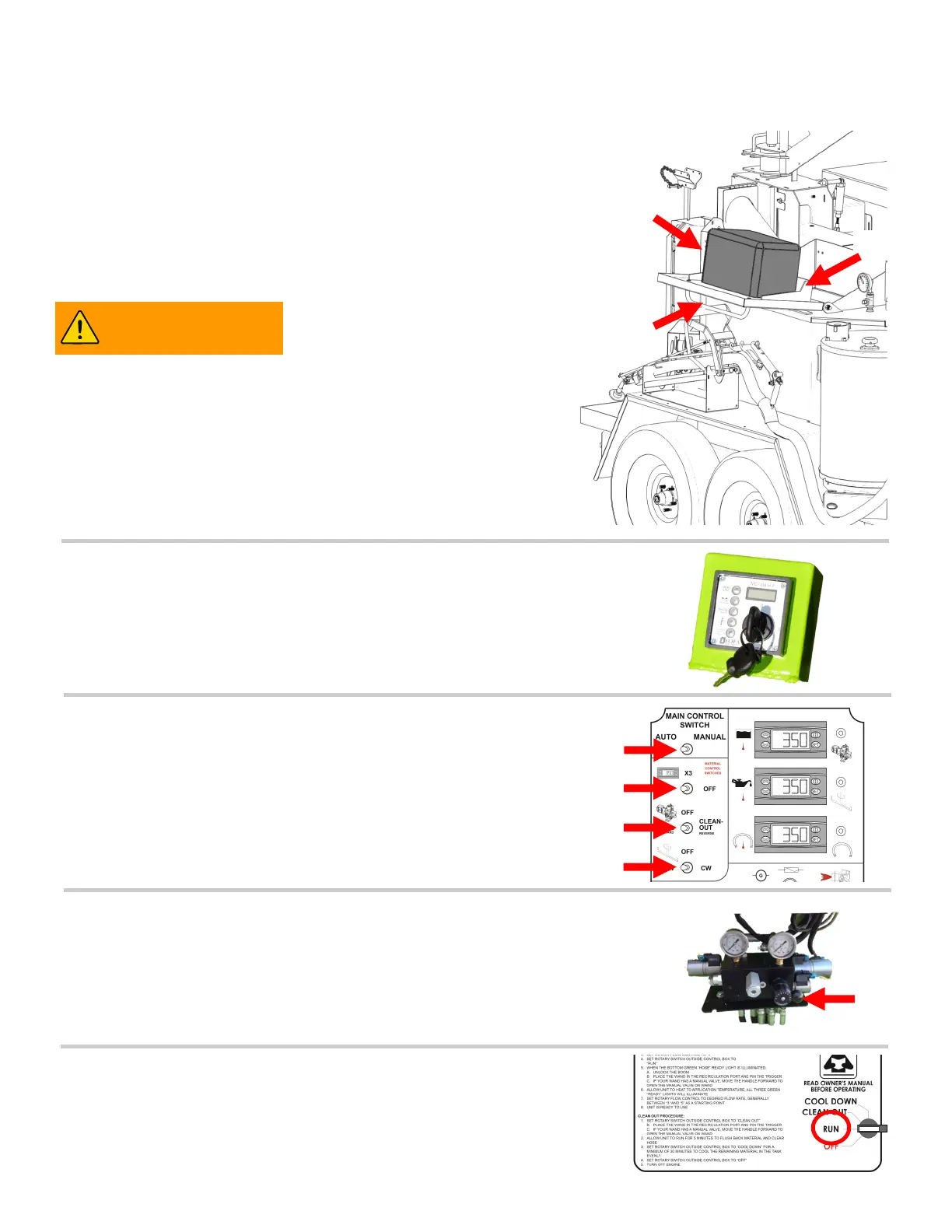

LOAD FRESH SEALANT MATERIAL INTO TANK:

All sealant material must be clean. Keep all foreign matter

out of melting tank to avoid damage to pump and systems.

1) Open the material door (A) and place the block of sealant

material (B) on the open door against the holder (C).

2) Push door to the closed position.

TO PREVENT CONTACT WITH

HOT SEALANT DO NOT DROP MATERIAL INTO THE MELTER

WITH EITHER OR BOTH DOORS OPEN.

LOADING OPERATOR MUST WEAR ALL PROTECTIVE

CLOTHING COVERED ON PAGE 4.

LOAD MATERIAL FROM GROUND ONLY. NEVER CLIMB ON

THE TRAILER TO LOAD.

M-Series Start Up Procedure

1. START ENGINE:

A) Turn key on engine control to “ 1”.

B) Allow 3-5 seconds to heat glow plugs. (Flashing green

light will turn to solid green)

C) Turn key to “ 2” and release when engine starts.

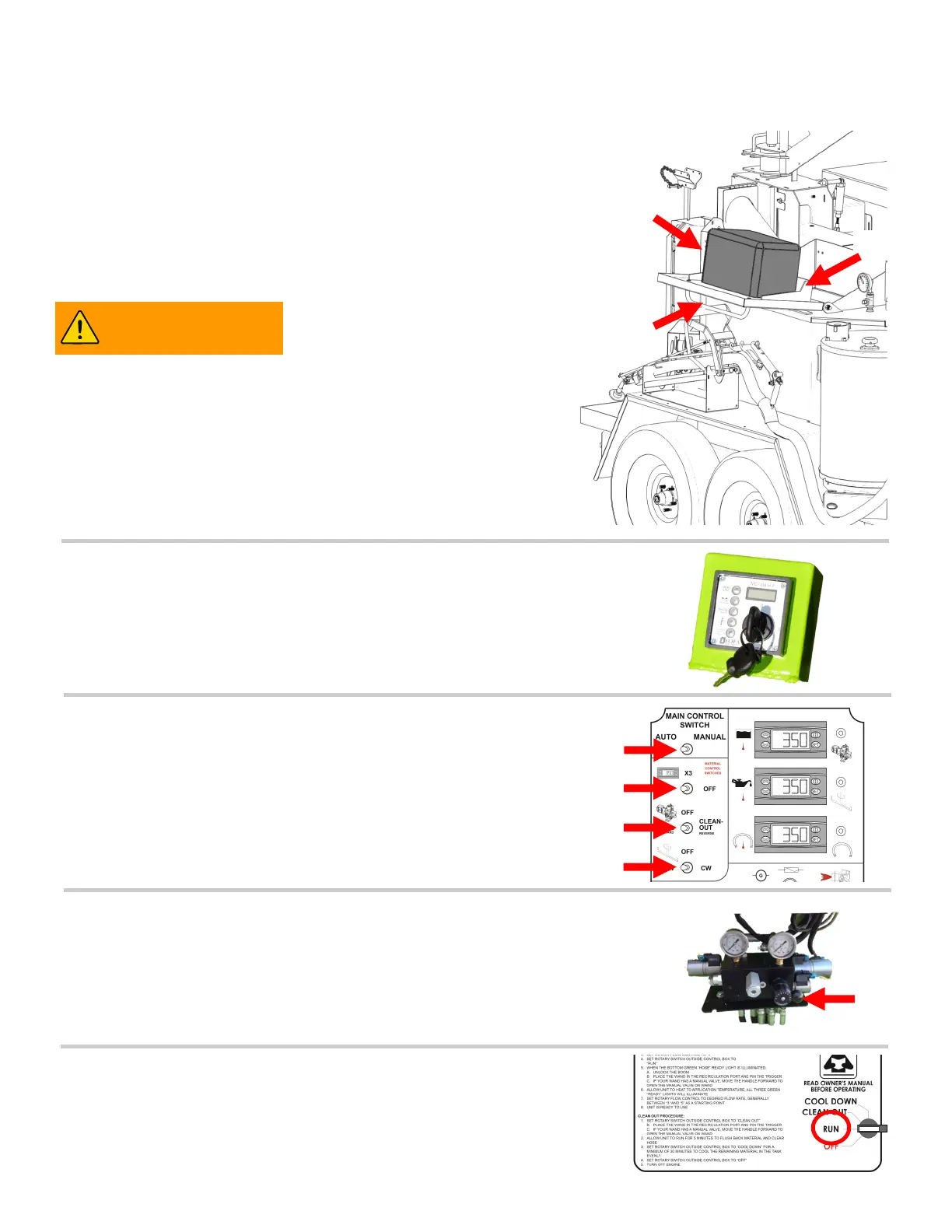

2. VERIFY SWITCHES ON CONTROL PANEL:

A) Verify main control switch inside control box is set

to “AUTO”.

B) Verify ALL the switches inside the control box are

in their left most position.

3. SET ROTARY FLOW CONTROL TO 9:

A) Set rotary switch (A) on the hydraulic block to “9” for maximum

sealant material flow during the start up process.

NOTE: Remember to return the flow control back to your start-

ing point setting before beginning sealant material application.

(B)

(C)

(A)

4. POWER UP CONTROL PANEL:

A) Set control panel rotary switch on front (outside)

of control box to the “RUN” position.

(A)

WARNING

Loading...

Loading...