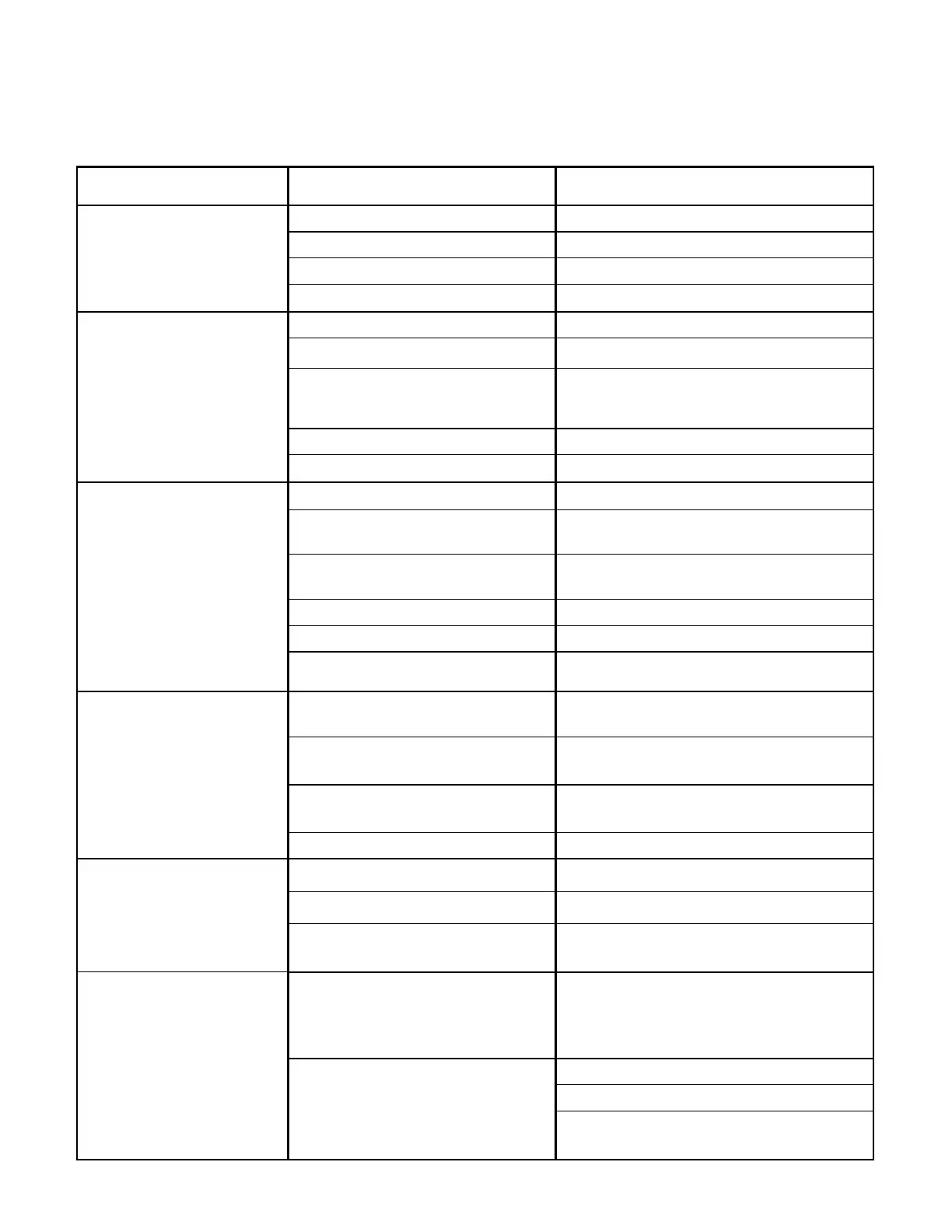

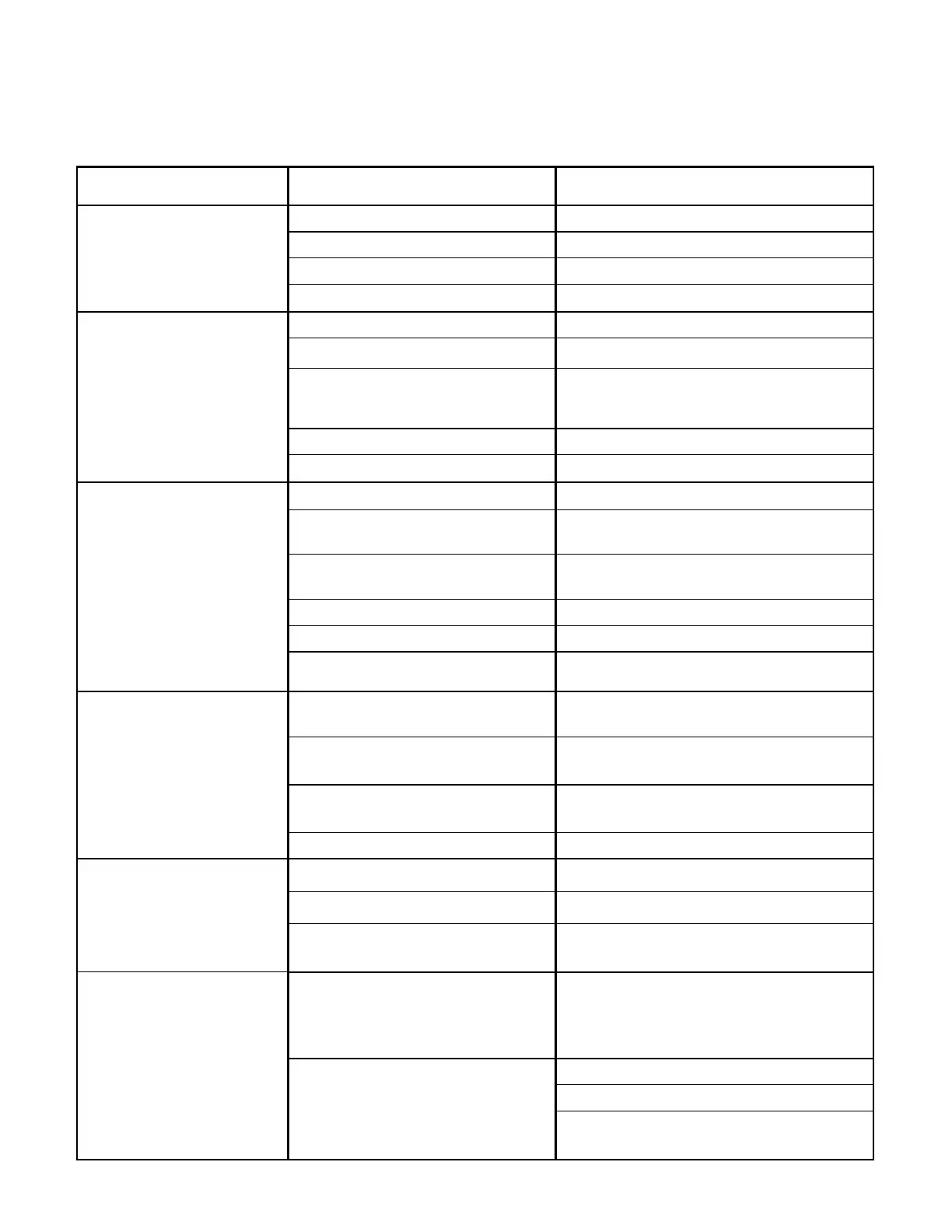

35

M-Series Trouble Shooting Guide

Problem Cause Solution

Burner will not ignite

Fuse burned out Check 20A fuse at sub control panel

Burner relay inoperative Check for 12VDC at relay

Primary control fuse Check control switch fuse

Thermocouple(s) inoperative Replace thermocouple(s)

Agitator will not rotate

Fuse burned out Check 10A control switch fuse

Sealant material not hot enough Allow material to heat longer

Too many biscuits added at one

time

Continue heat up and reverse agitation to

break biscuits free

Low hydraulic oil level Check hydraulic oil Level

Worn agitator motor Replace agitator Motor

Material pump will not

rotate

Fuse burned out Check 10A control switch fuse

Sealant material not hot enough Allow material to heat longer

Too much cold material left in

lines from previous use

Heat plumbing and valve

to melt material

Low hydraulic level Check hydraulic oil level

Foreign object lodged in line Locate/remove foreign object

Pump worn or damaged

Confirm pump switch on control panel is

in “SEAL” forward position

Material pump rotates but

does not pump material

Pump rotating in wrong direction Reverse pump switch

Pump inlet line plugged

Check sealant tank grid and lines for

obstruction

Too much cold material left in

lines from previous use

Heat plumbing and valve

to melt material

Pump worn or damaged Replace pump

Sealant heat up time slow

Burner orifice clogged Remove orifice and clean/replace

Heat transfer oil is worn out Check oil level. Replace if necessary

Too much old material on tank

walls

Clean material tank

Material recirculates but

will not flow through

sealing nozzles.

Sealing nozzle valve not

completely closing or worn out

Realign valve or replace

Actuator not turning valve

Realign valve or replace

Loading...

Loading...