34

M-Series Maintenance - Tank Burner

Bleeding The Fuel Supply Line (Older Melter Units):

More recent CIMLINE Melters us a Clean-Cut Fuel Pump on the Beckett Burner units. These more

modern fuel pumps are self priming and this process should not be needed.

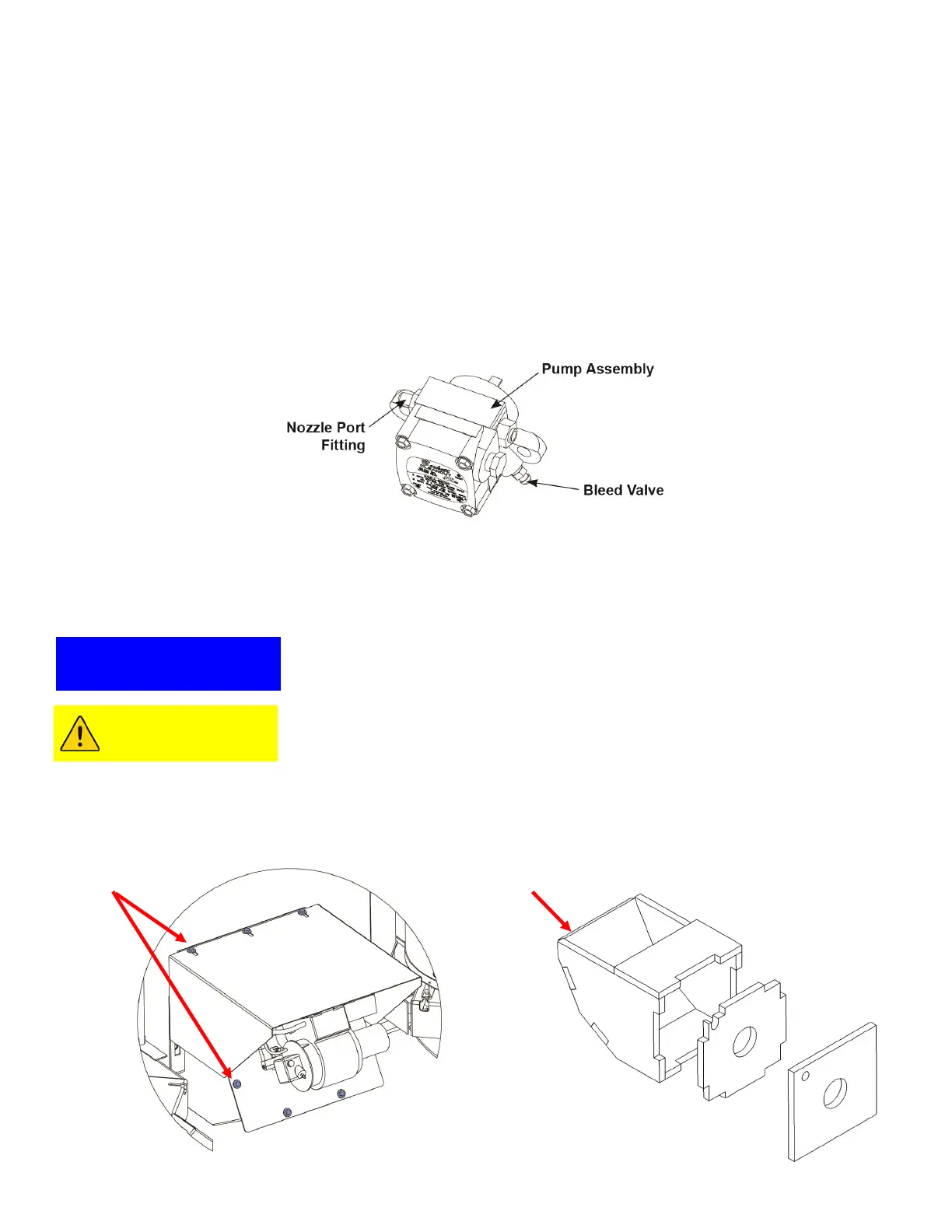

In the case of older Beckett Burner units there may be a need to bleed air from the fuel line if the

burner has run completely out of fuel. To bleed the pump, attach a clear plastic hose over the vent

fitting (C). Loosen the fitting and catch the fuel in an empty container. Tighten the fitting when all air

has been purged from the supply system. Note: If the burner stops after a flame is established, the

unit probably requires additional bleeding. Continue to bleed the system until the pump is primed and

a flame is established when the bleed valve is closed.

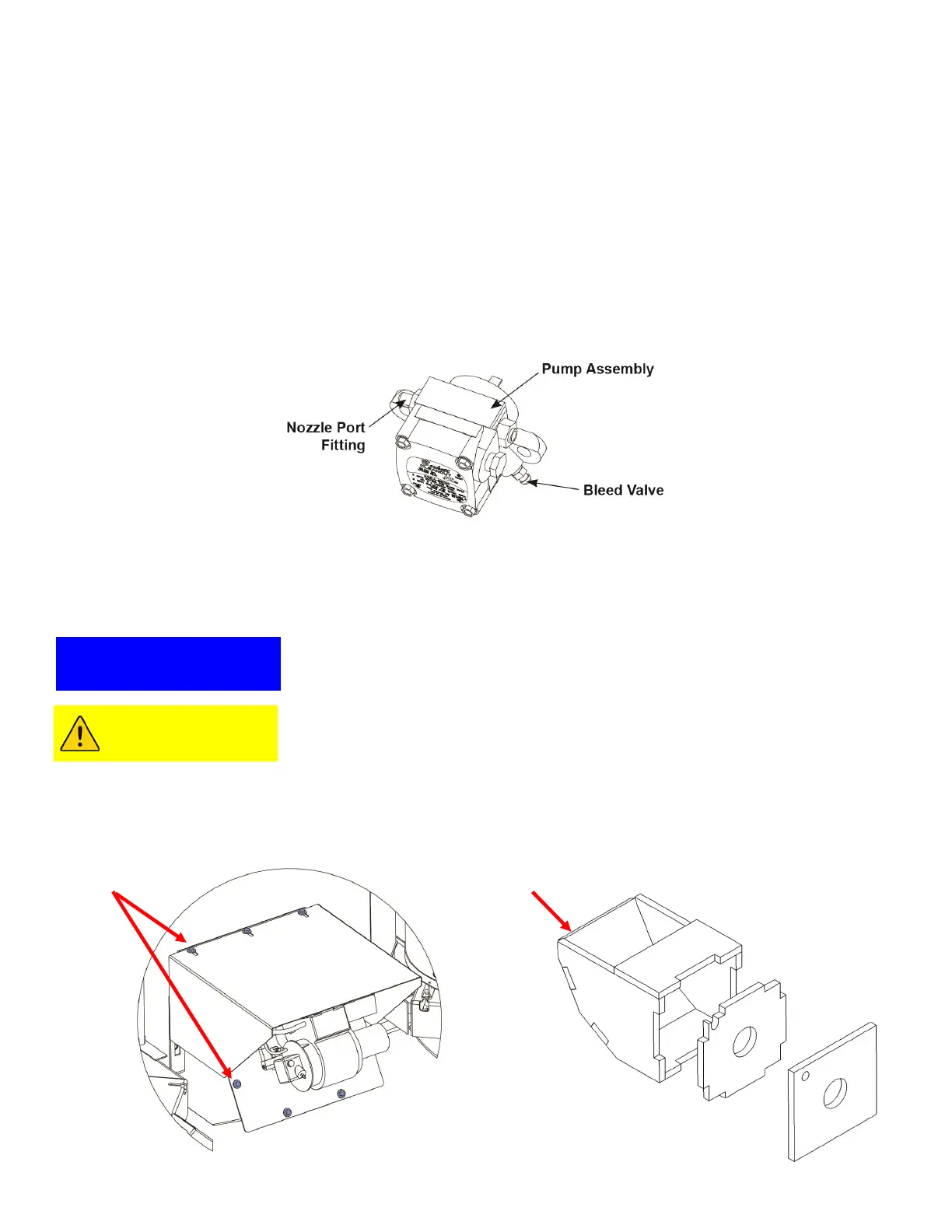

Tank Burner Chamber Lining:

After initial 200 hours of operation, the chamber lining must be inspected. Cracks in lining may occur

and should be regularly inspected and monitored. If cracks expand excessively a new lining kit should

be ordered to replace worn lining.

Remove tank burner mount bolts (A) and pull out burner and mount. Inspect lining (B) for excessive

cracking. If cracks exceed guidelines, contact your CIMLINE dealer to purchase a replacement PN#

403400 Burner Chamber Lining Kit.

(A)

1

2

3

4

5

6

7

8

(B)

(C)

Assemble chamber insulation

in the order shown 1-8.

Do not run machine if cracks are wide enough to allow flame to

contact the metal combustion chamber walls or if any piece has

broken loose. Do not attempt to repair cracks.

NOTICE

Contact with lining may cause skin or eye irritation, wear long

sleeve shirt, gloves, and goggles when inspecting lining.

CAUTION

Loading...

Loading...