Model FLE Assembly Pressure Vessel Assembly

750-192 2-7

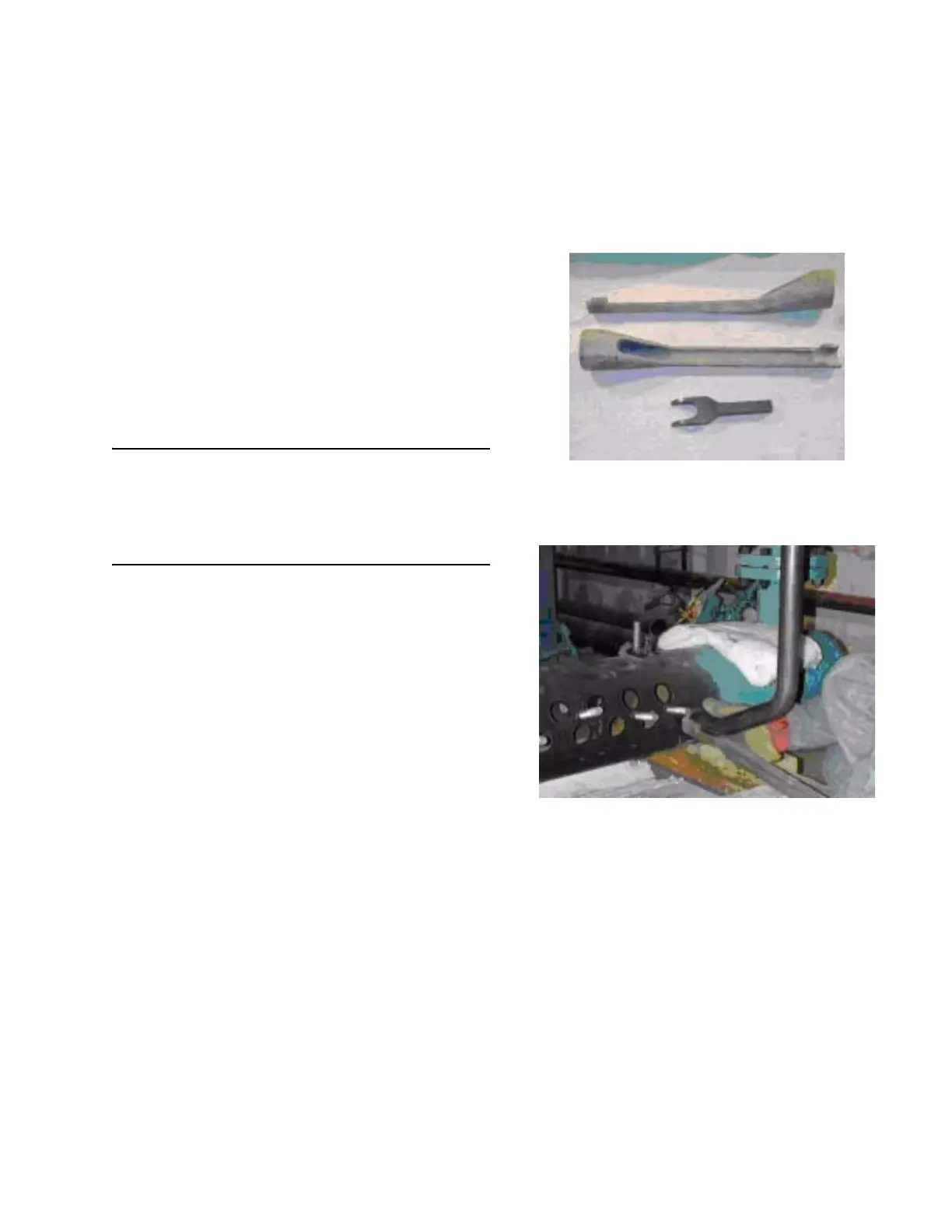

Use a modified vice-grip clamp to secure the driving

tool to the ferrule.

Before installing the tubes, apply a thin, uniform

coat of Lock-Tite sealant (Part Number 872-716) to

the first 1/2” of the ferrule and the drum socket

surfaces.

Both ends of the tube should be inserted into the

drum holes before the tubes are driven into place.

The driving tool must be securely held in place

against the tubes during the driving operation with

vice-grip type clamps (Figure 2-14).

Ferrules must be driven in to expose only 3/4 inch of

the tapered portion of the ferrule.

CAUTION - The tube driving tool must be securely

held against the tube during the driving operation.

Failure to do so is likely to result in damage to the

driving surfaces of the tube ferrule and the tube

driving tool.

The orientation of the first tube installed to the

drums will affect the location of all of the following

tubes. Check that the drums are level using a

bubble level. With the first tube loosely installed in

the drum sockets, place the bubble level against the

tube and adjust the orientation of the tube so that it

is perpendicular to the drums. When the orientation

of the tube is correct, drive them into the drums.

The tube ferrules must be correctly aligned with the

tube sockets when the tubes are being driven into

place in the drums. Although the taper on the

mating surfaces of the tube ferrule and tube hole

provide for alignment of the tube, misalignment

(cocking) may occur and is likely the cause of a tube

becoming difficult to drive before the required depth

of insertion is reached. In this case, remove the

tube, check the ferrule and socket surfaces for

damage and repair or replace it if necessary.

Reapply Lock-Tite® sealant to the ferrule and

socket surfaces, and reinsert the tube ends in the

drum sockets. After checking the tube alignment,

drive the tube ferrules into place with the difficult

ferrule first.

To achieve a tight fit between tubes, drive the tubes

to a uniform depth.

Install the remaining tubes on the right side, follow-

ing the proper tube pattern sequence as shown in

Figure 2-19, 2-20 and 2-21.

Figure 2-11. Tube Driving tools and Tube Removal

Tool

Figure 2-12. Driving lower end of first tube

Loading...

Loading...