General Description Model FLE Assembly

1-4 750-192

3. Order of Assembly

The assembly of the pressure vessel and casing will

be easier if all of the component parts are sorted

and arranged to be easily accessible in the working

area. If there is not enough room in the work area

for all the parts, only those that will be needed for

the day’s work should be brought into the work

area.

Assembly of the boiler can be regarded as a four

step process. The four steps are:

1. Pressure vessel assembly and

water side leak test (Chapter 2)

2. Casing assembly and fireside leak

test (Chapter 3)

3. Burner assembly and gas train

installation (Chapter 4)

4. Trim installation (Chapter

4)

The boiler components are listed in Table 1-1.

Special assembly equipment likely to be required for

each part of the assembly process is listed below.

There are three different types of insulation used in

the construction of the Cleaver-Brooks Flextube

Model boilers:

• Ceramic fiber- white, flexible, dry insulation, supplied

in bulk roll or block

• Wet-pack- white, flexible, insulation saturated with

curing agent, supplied as rolls in sealed bags

• Fibrefax- white insulation, supplied in tubes

4. Pressure Vessel Assembly

Assembly of the pressure vessel will require the

following components (also refer to the packing list):

• Top and bottom drums

• Fanged bolts and gaskets

•Boiler tubes

• Base assembly

• Ceramic fiber pass seal insulation

• Tube sealant (LockTite 680)

• Anti-seize lubricant

• Tube retainers and fasteners

• Spray adhesive

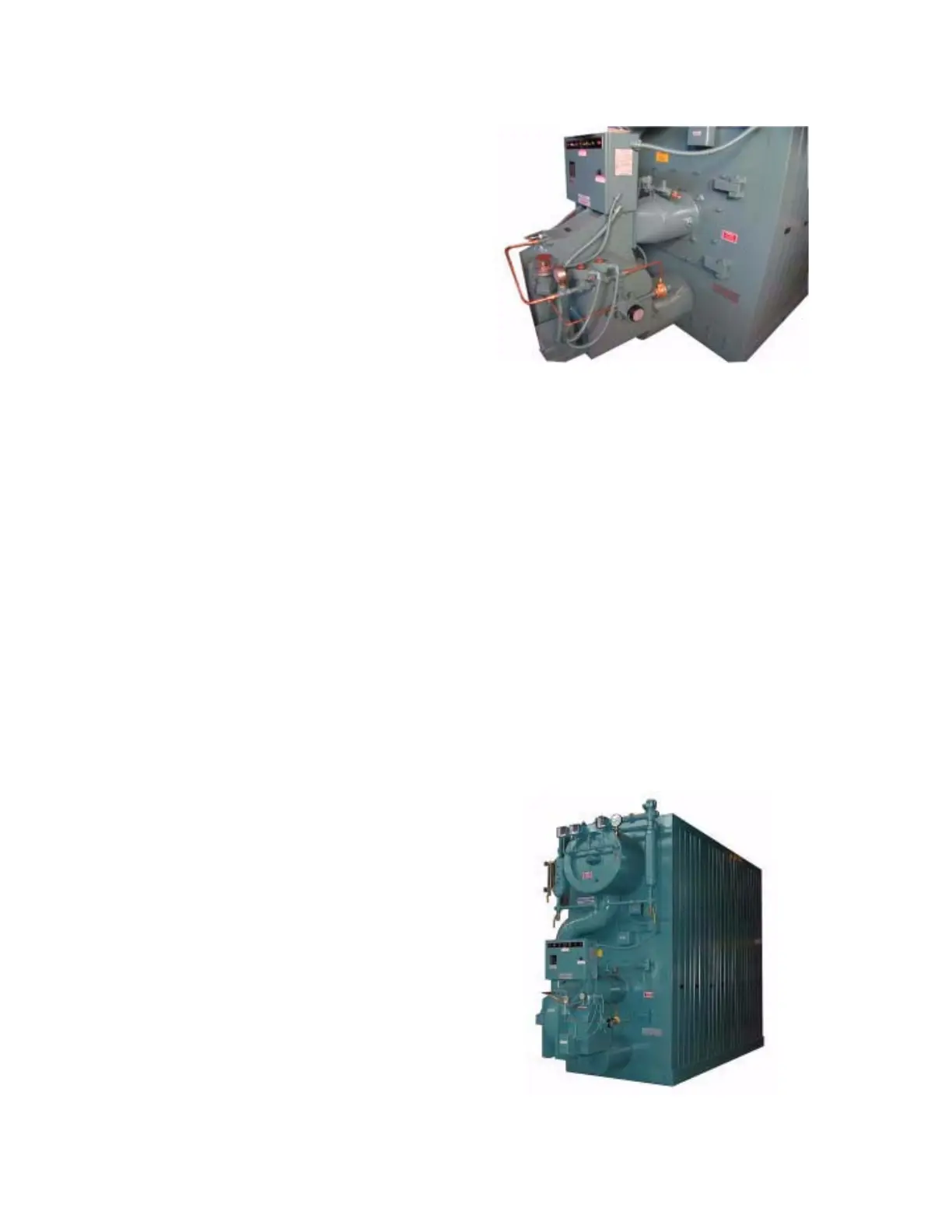

Figure 1-3. ProFire burner mounted on a Model FLE

boiler

The following tools will be required to assemble

the pressure vessel:

• Small and large level

• Vice-grip clamp or strap wrench

• Chain fall and support strapping

• Lifting support

• Tube driving tools and 16 or 20 lb sledge hammer

•5/8” die

• Dulled chisel

• Slings and chains

• Lifting and support devices (come-along, ratchet

hoist, etc.)

• Caulking gun

• Safety glasses, hearing protection and gloves

• Suitable lifting equipment will be required to handle

the placement of the drums and the mounting of the

completed vessel to the base

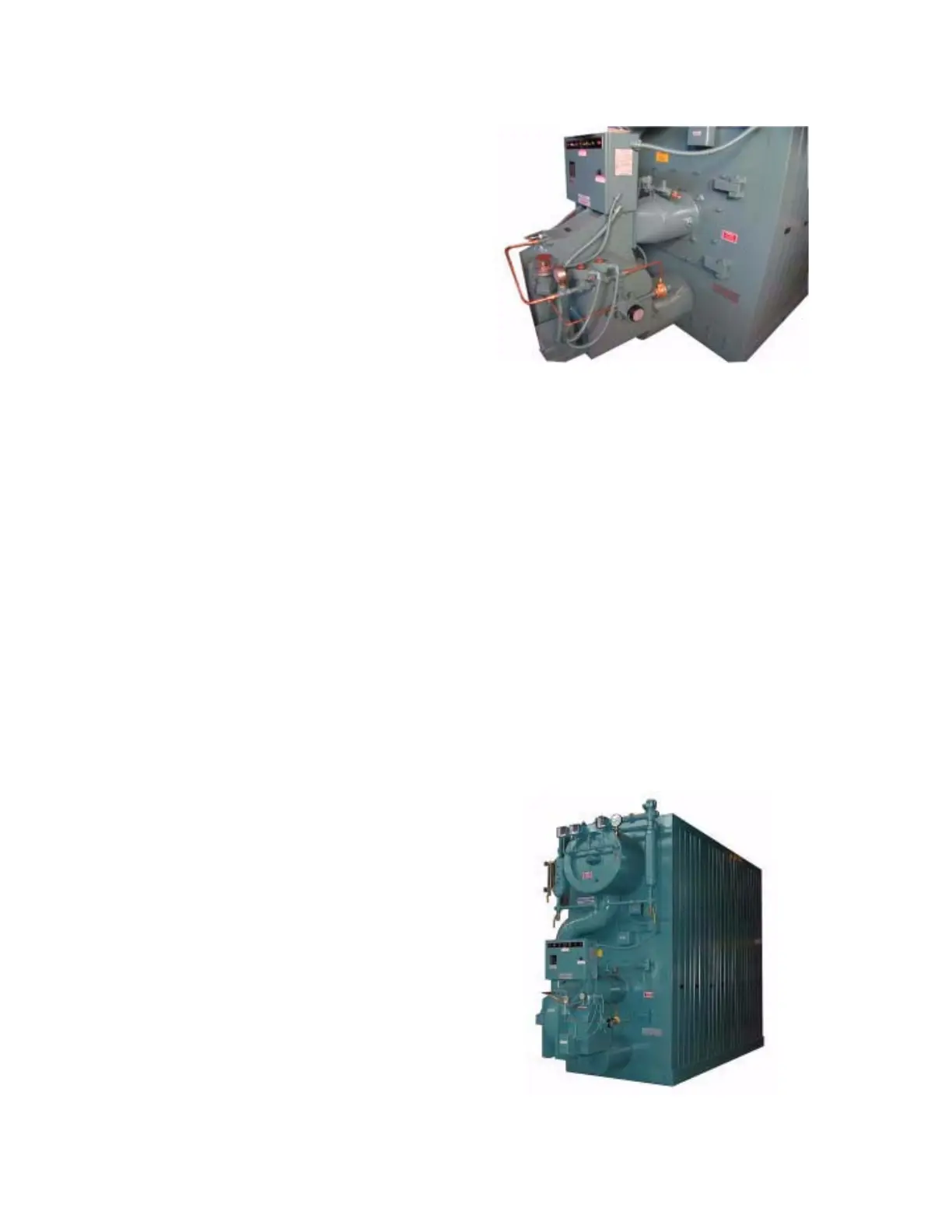

Figure 1-4. Model FLE (Steam)

Loading...

Loading...