Model FLE Assembly Pressure Vessel Assembly

750-192 2-15

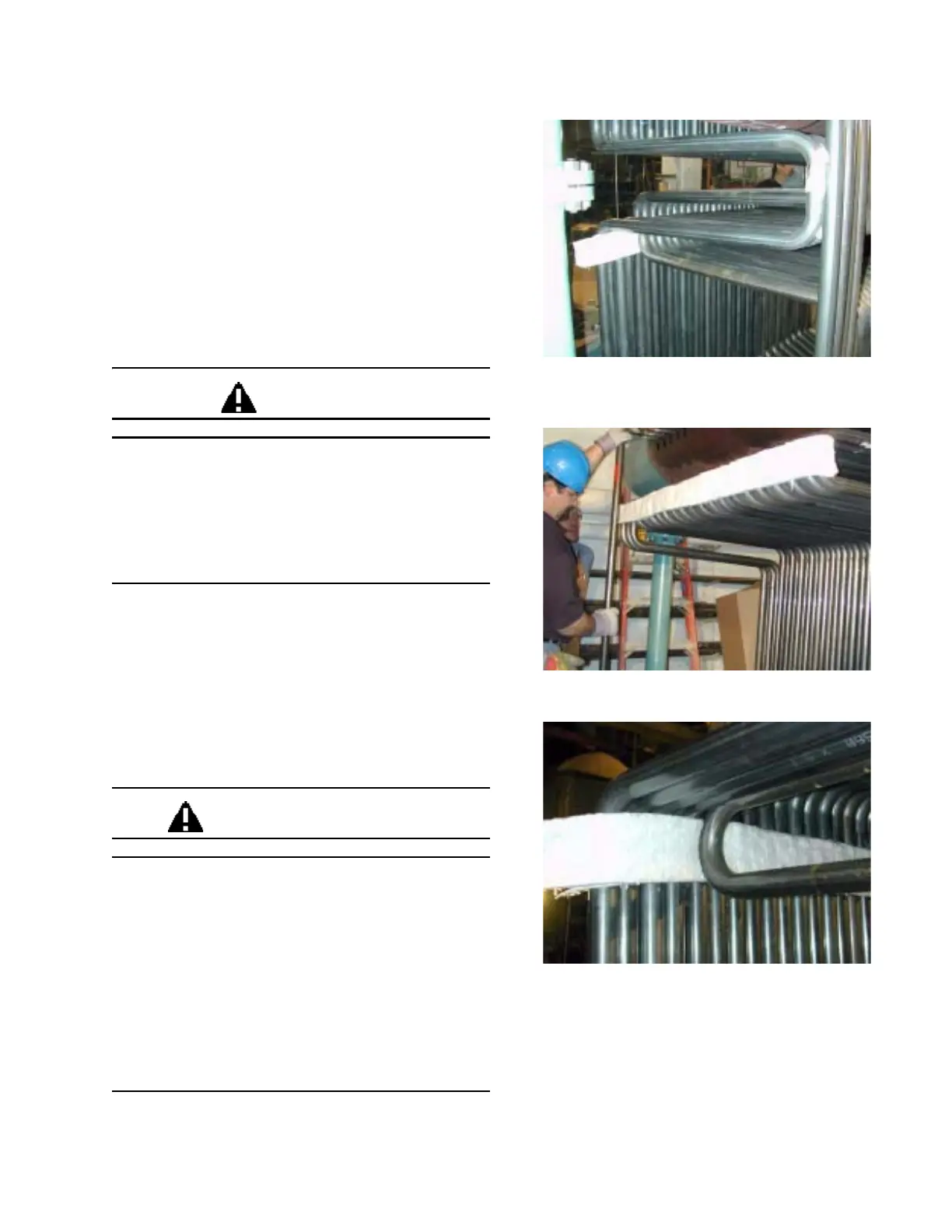

9. Pass Seals

Two lengths of ceramic fiber insulation seal the

sides of the upper gas passes. The pass seals are

installed between the contact areas of the left and

right side tubes as shown in Figure 2-26. The seals

are compressed and held in place as the left side

tubes are driven into place. Cut the seals from the

supplied bulk material. Use a spray glue to hold the

insulation in place while installing the left side

tubes.

WARNING

Gloves and an appropriate respirator should

be worn when handling or working with

insulating materials. Handling or working with

insulating materials may result in skin

irritation or may pose a health risk from

inhaling insulation fibers.

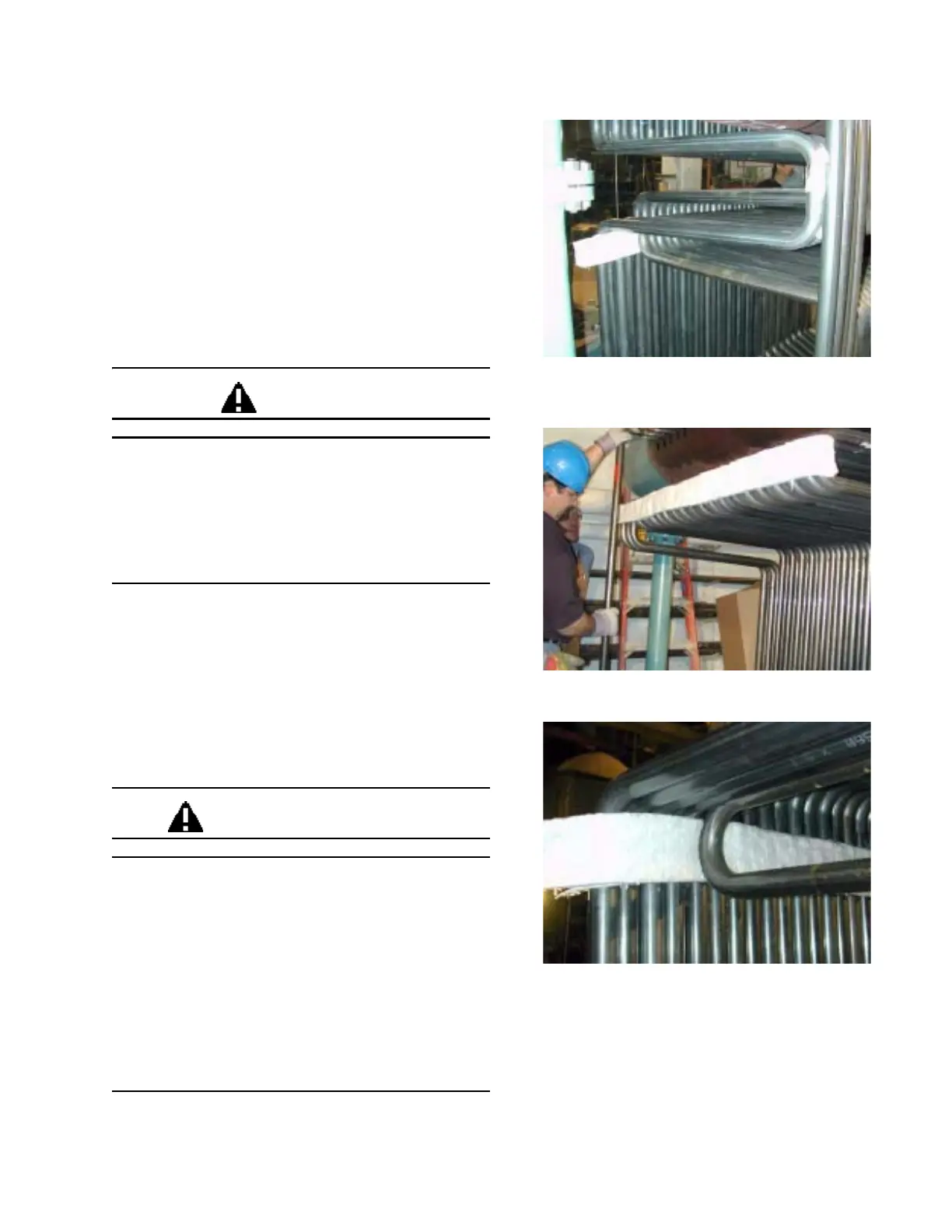

Proceed with tube installation in the same manner

as with the previously installed right-side tubes,

following the proper tube pattern sequence for the

right-side tubes as shown in Figures 2-19, 2-20 and

2-21.

CAUTION

Model FLE boilers are equipped with two

lifting lugs located on the upper drum. The

lugs should be used to lift or to pull the boiler.

If the vessel is a Hot Water unit, be sure the

front spreader is securely bolted in place prior

to lifting or moving the unit. Do not lift or move

the boiler by pushing, prying, or pulling on the

tubes, or downcomer pipe. Failure to follow

these instructions could result in equipment

damage.

Figure 2-26. Install pass seals before installing left

side tubes

Figure 2-27. Upper pass seal installed

Figure 2-28. Lower pass seal installed

Loading...

Loading...