Pressure Vessel Assembly Model FLE Assembly

2-6 750-192

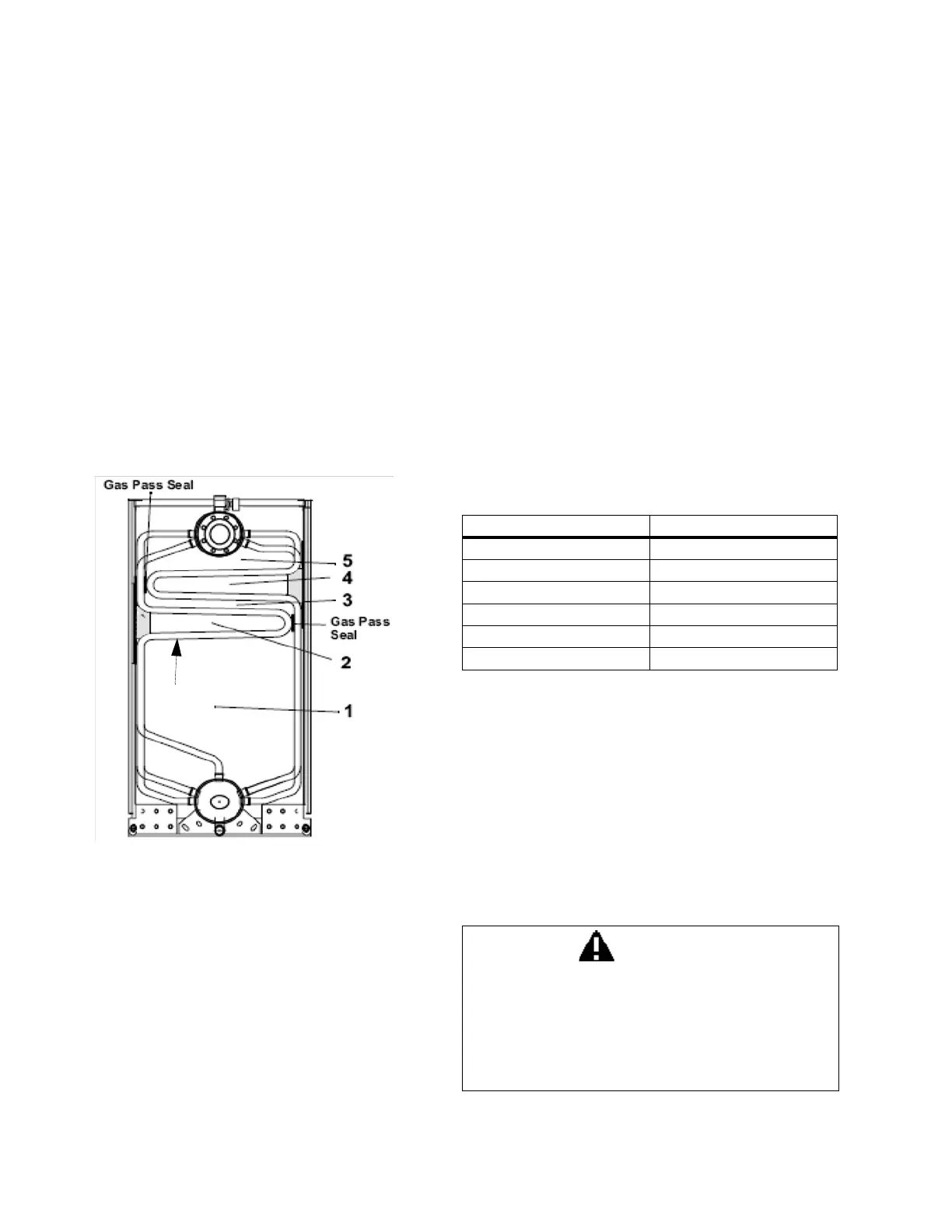

7. Tube Installation

Tubes are formed in eleven different patterns in

order to provide a five-pass gas flow path through

the boiler (Figure 2-10). Tubes can be identified by

visually comparing the tube profile to those shown

in Figures 2-17 and 2-18.

Figures 2-19, 2-20 and 2-21 show the proper

location for each tube pattern at the left and right

sides of the pressure vessel assembly. Tube

locations are the same for steam and hot water

units. The number at each pressure vessel tube

location in Figures 2-19, 2-20 and 2-21 refers to

the tube pattern numbers shown in Figures 2-17

and 2-18.

Figure 2-10. Cross section showing tubes forming

the five gas passes

Note: The horizontal tubes between the first

and second pass with a gap greater than 3/32”

must be packed with ceramic insulation.

One member of the assembly team should become

familiar with the boiler’s tube patterns and keep

track of the tubes as they are installed.

Inspect the tube ferrules for flat spots or scuffs due

to shipping. Repair or replace any tube that may

have been damaged during shipment

Tube installation should begin at the rear of the

pressure vessel, in order to take advantage of the

rigidity provided by the downcomer pipe. The

pressure vessel will become progressively more rigid

as additional tubes are installed.

Refer to pages 2-9 through 2-13 to determine the

top and bottom of the tubes. Install all of the tubes

on one side of the boiler.

Install the inner row left-side tube before the outer

row tube. Install the tubes in sequential order. Begin

installation of the left side tubes with a PATTERN 4

tube installed in the second to last position in the

upper drum (last tube hole in the bottom drum).

Install the vent tube PATTERN 3 next, followed by

the remaining left side tubes.

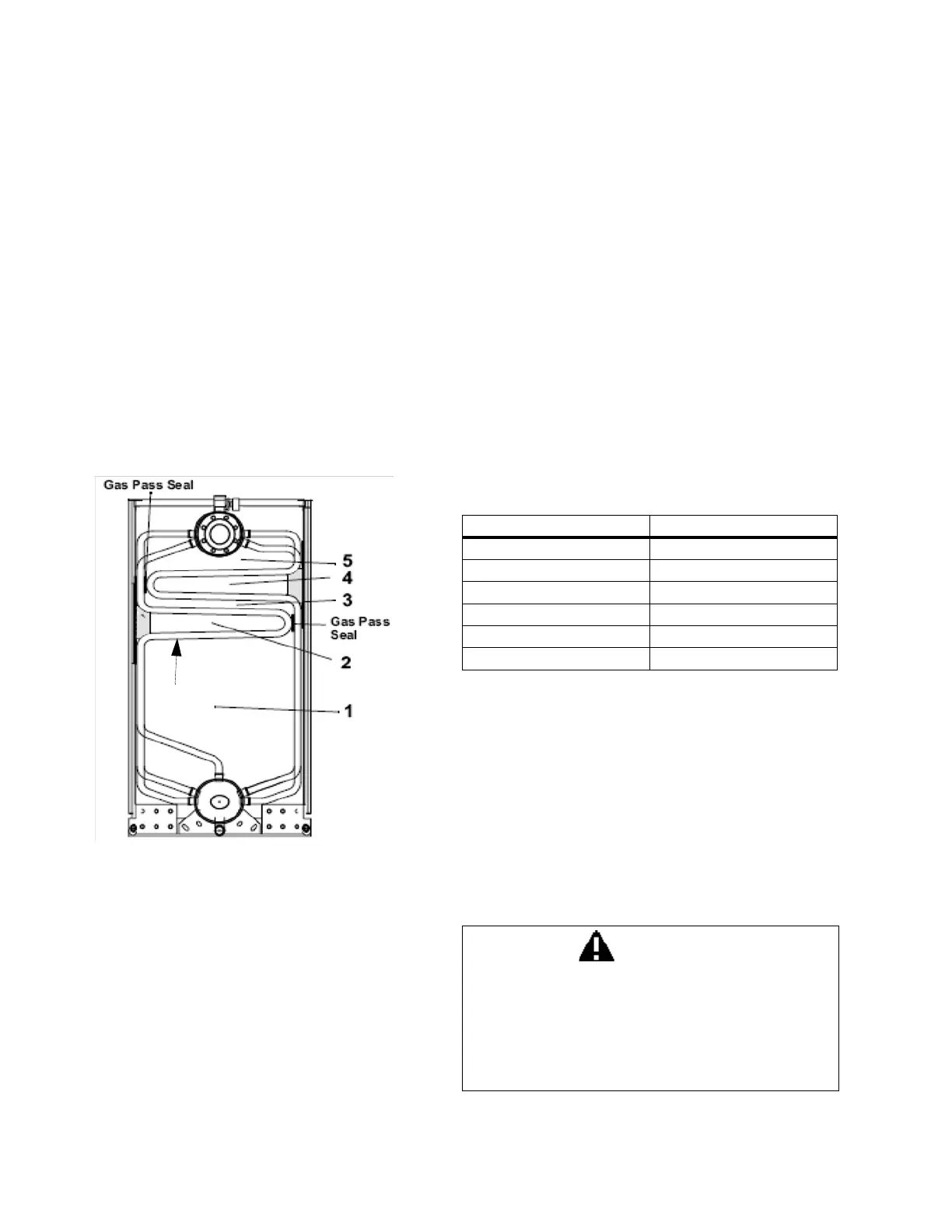

Table 2- 3: Inner and Outer Tube Patterns

Tube ferrule and drum socket surfaces must be free

of any dirt, corrosion, or petroleum-based lubricants

in order to ensure that the tube ferrule and sealant

work effectively

Tubes are driven into place with a tube driving tool,

(Figure 2-11) which is seated against a raised

shoulder on the tube ferrules. A 16-pound

sledgehammer is recommended for driving the

tubes.

INNER ROW TUBES OUTER ROW TUBES

Tube Pattern 4 Tube Pattern 1

Tube Pattern 5 Tube Pattern 2

Tube Pattern 9 Tube Pattern 3

Tube Pattern 10 Tube Pattern 6

Tube Pattern 11 Tube Pattern 7

Tube Pattern 8

WARNING

Heavy-duty work gloves and hearing and eye

protection must be worn by assemblers when

driving boiler tubes. Failure to heed this

warning may result in damage to the eyes,

hearing impairment, or serious personal

injury.

Loading...

Loading...