Casing Assembly Model FLE Assembly

3-12 750-192

Figure 3-18. Set tape measure to sight port height

(height varies with flextube size)

Figure 3-19. Overall tape measure length should

match sight port height

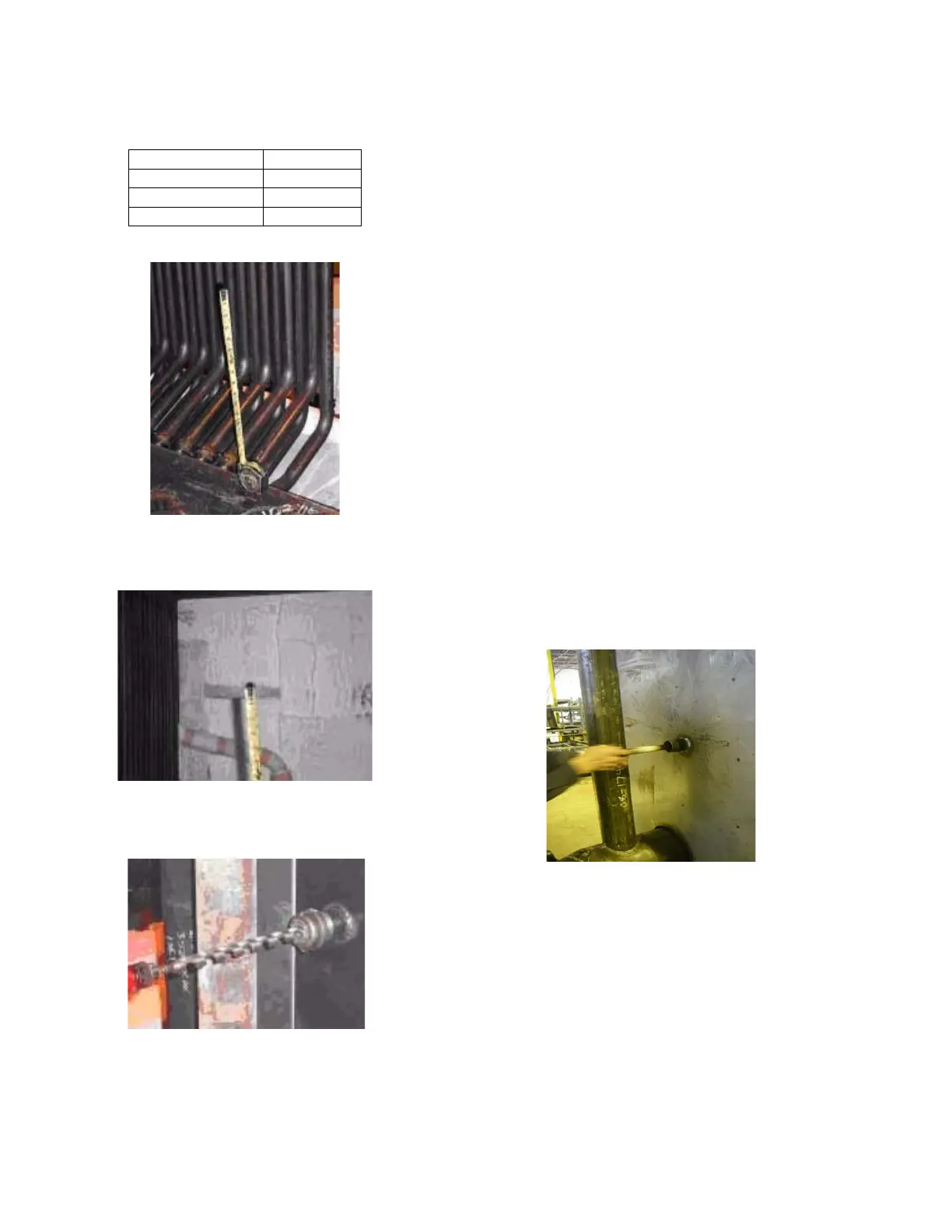

Figure 3-20. Drill out insulation (drill level, pointing

toward tape measure)

4. Drill Rear Sight Port

The sight port drilling process is required to remove

the insulation from inside the rear wall to allow the

burner flame to be viewed during operation.

1. Set your tape measure to the length shown in the

table and place it at the front of the lower boiler drum

(where the front casing wall will be). This dimension

is the same as the distance from the top surface of

the lower drum to the centerline of the sight port

(Figure 3-18, 3-19).

2. Drill a 1” hole through the insulation in the center of

the sight port, parallel to the drum (Figure 3-20).

The tape measure is in approximately the same loca-

tion that the flame will be.

3. Obtain a 1” OD tube x 16” long (3/4” conduit) to use

as a guide pipe. Use the guide pipe as an applicator

and add rigidizer solution (part# 872-00458, not

included in FLE boiler assembly) to the outside of the

pipe and apply it to the inside diameter of the hole in

the insulation. Dip the pipe and coat the insulation

four to six times from the rear of the boiler and repeat

from inside. Ensure that the insulation is thoroughly

coated with the rigidizer solution (Figure 3-21).

Figure 3-21. Coating sight hole with rigidizer

Table 3-1: Sight port height from lower drum

Flextube Size Dimension

250 13”

350 18”

500/800/1100 20”

Loading...

Loading...