Model FLE Assembly Casing Assembly

750-192 3-11

Figure 3-15. Use bar clamps and wedges to align

wall

Figure 3-16. Insulation in the gaps

Figure 3-17. Use bar clamps and wedges to align

wall

4. With bar clamps, clamp the walls together at the cor-

ners of the wall and clamp the entire wall to the base

of the boiler (Figure 3-15).

5. Make sure that the walls are flush with each other

and secure all of the bolts.

6. Remove the clamps.

7. Check that the sides of the wall line up with the base

angles. If not, loosen the bolts and/or nuts on the

bolting plates and move the wall. If the wall will not

line up exactly, then center the wall in relation to the

base angles. Tighten the nuts and bolts on the bolt-

ing plates to secure the walls to the base.

8. Attempt to slide a box cutter into all of the seams

where insulation is visible. If the knife is able to

enter, then gasses can escape. Tighten the bolts and

repeat the last three steps.

9. Trim all of the visible insulation from the joints.

10. If necessary, use the wedge described earlier, to

make the wall stand upright.

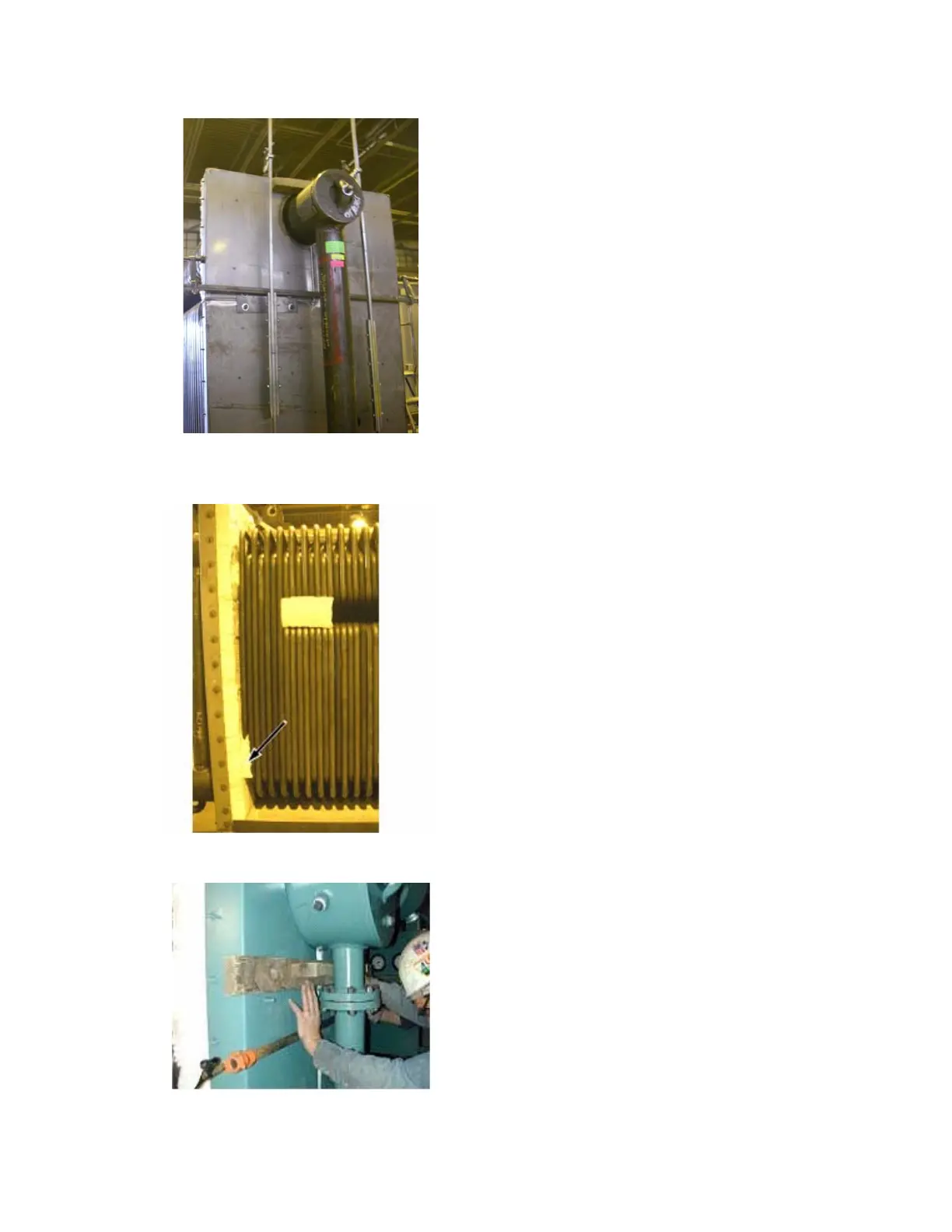

11. Install a pyro-log insulation block (872-911) in the

pass opening near the rear and in the gap left by the

tubes at the bottom (Figure 3-16). The insulation

block should be compressed together slightly and

should be installed flush with the outside of the

tubes. They should be turned vertically to fill in the

turn around area. Trim to fit as necessary.

Loading...

Loading...