Technical and instalation

manual FLOW 38 Batch Page 16 (of 49) COMAC CAL

s.r.o.

It is necessary to do the tightening three times, whereas for the first time, to 50% of the maximum

torque according to the above given Table. For the second time, to 80% and for the third time, to 100%

of the maximum torque. We recommend checking the screws/bolts for tightening some 24 hours after

installation of the meter.

When installing the flow sensors over 200 mm, it is necessary to follow, except for the above

mentioned rules, also simultaneous tightening of parallel screws on both opposite flanges to avoid

possible damaging the electrodes or the measuring tube (symmetrical tensioning of the lining).

If the flanged joint is not tight, although all of the screws are tightened closely, these must not be

tightened more but slackened on the opposite side to the untightness and tightened on the other side.

If the untightness manifests itself even after that, it is necessary to check the sealing surfaces for

scratches or mechanical impurities. If the scratches or any other damage are deeper than some 15% of

the thickness of the flange, it is possible to remove them using fine emery paper.

In case of the threaded connection, it is necessary to check, while tightening, the screwed connection

on the sensor so that torsional displacement is be avoided.

S

e

al

The turned up part of the lining does not carry out the function of sealing so it is necessary to insert

the appropriate seal precisely centred between the sensor and the pipeline. If the sealing extends in

some place into the flow profile, it makes whirls and reduces the measurement quality. Use the seals

compatible with the liquid and 5mm thick. Do not use graphite or any other electrically conductive

material to hold the sealing in place during installation. It could influence the measuring signal

accuracy.

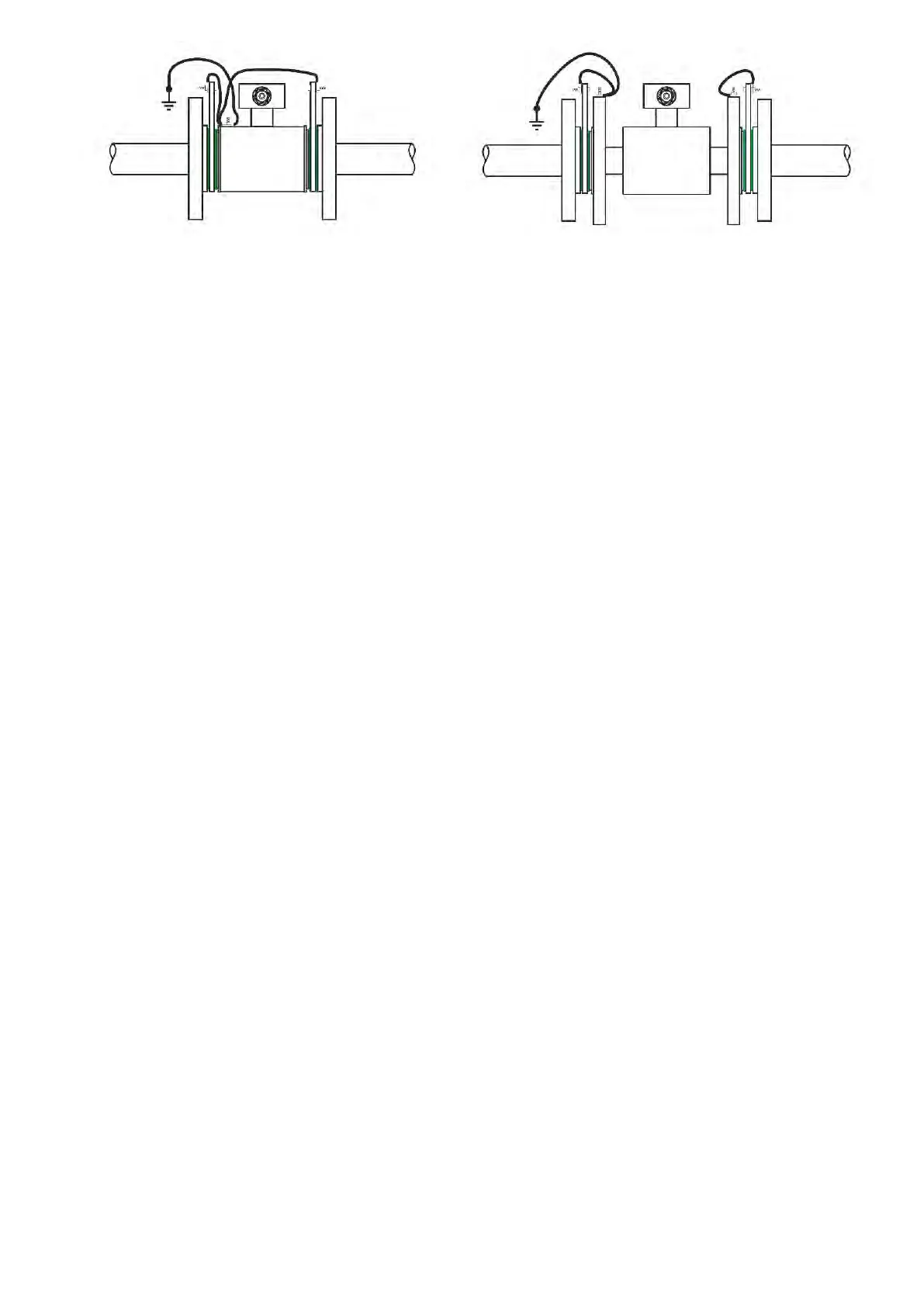

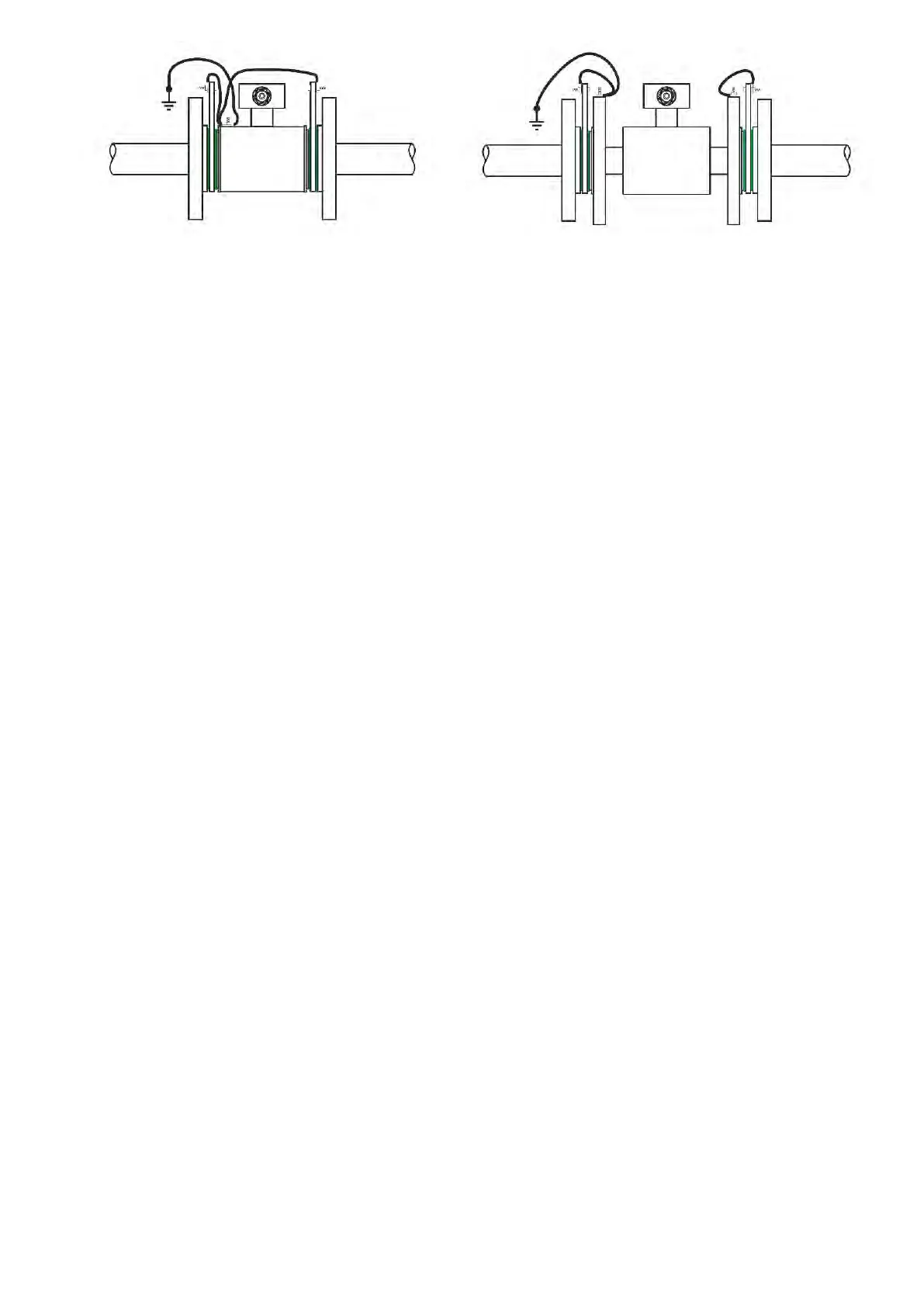

Earthing

For reliable and correct operation of the induction sensor it is necessary nto provide proper protective

and working eathing. The earth line must not transmit interference voltages so the other electrical

devices must not be earthed by means of this line.

The flow sensor is provided with the M5 earthing screw of stainless steel with a washer and nut for

proper connection of the sensor body with both counter-flanges of the metallic pipeline. The earthing

cable lug is screwed there and it should be conductively connected with the counter-flanges. On the

counter-flanges, it is recommended their connection to the welded crews or into a threaded hole.

Connecting under the fixing screws of the flange is not suitable as they may corrode with time and

cause failures in measurement.

However, if it is not ensured that the counter-flanges are in dicert contact with the measured media and

they are conductive, the earthing rings must be used, refer hereinafter.

Loading...

Loading...